Slagging agent used in converter steelmaking, and preparation method thereof

A converter steelmaking and slagging agent technology, applied in the field of metallurgy, can solve the problems of inability to achieve one-time molding, reduce the service life of the furnace lining, and the pellets cannot be stored immediately, so as to save processing steps, increase the viscosity of slag, and make The effect of slag fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

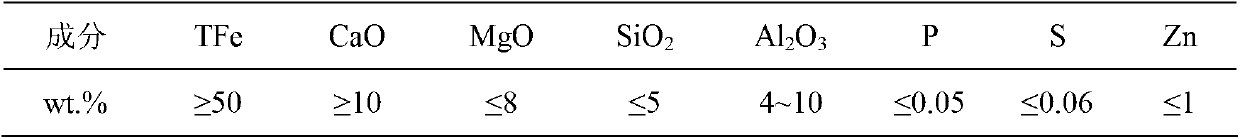

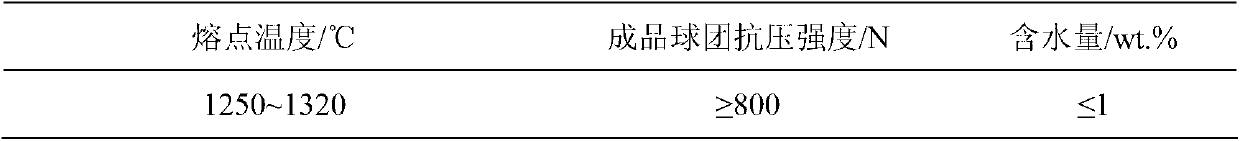

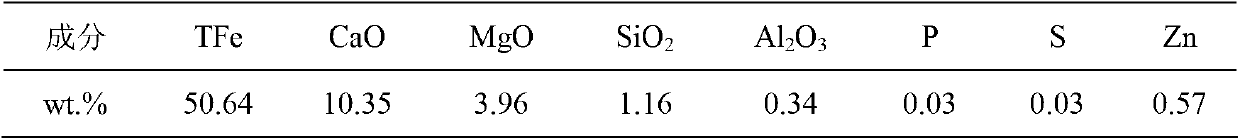

[0030] The slagging agent for converter steelmaking is prepared by adopting converter sludge, whose mass percentage is 52%, rolling steel oxide scale, whose mass percentage is 40% and adhesive, whose mass percentage is 8%. The chemical quality composition of the converter sludge is: total Fe50%; Fe 2 o 3 15%, FeO45%; SiO 2 2%, CaO15%, and the balance is necessary impurities. The chemical mass composition of rolled steel oxide scale is: total Fe80%, FeO43%, Fe 2 o 3 52%, S0.015%, P0.01%, and the balance is necessary impurities. The chemical quality composition of the adhesive is: light burnt Mg powder 50%, MgCl 2 Powder 50%.

[0031] The preparation method of slagging agent for converter steelmaking is as follows:

[0032] (1) The baking temperature of the rotary drying kiln is set at 800°C, and the converter sludge is dried, and the converter sludge is crushed and ground at the same time, and the particle size of the sludge is 2.5mm;

[0033] (2) being 52% converter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com