Preparation method of high refractive index semiconductor surface anti-reflection passivation composite structure

A high-refractive index, composite structure technology, applied in nanotechnology and other directions, can solve the problems of large reflection loss, low reflectivity, difficult to achieve semiconductor refractive index, etc., to improve efficiency, reduce reflection loss, and improve carrier collection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

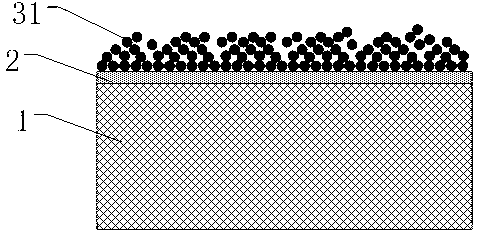

[0027] This embodiment provides a method for preparing a high-refractive index semiconductor surface anti-reflection passivation composite structure. The prepared composite structure is as follows: figure 1 The steps shown are as follows.

[0028]I. Prepare a layer of dense dielectric film 2 for passivating the surface on the surface of the high refractive index semiconductor 1 . Wherein the high refractive index semiconductor includes Si, Ge, III-V group semiconductor, III-N group semiconductor, II-VI group semiconductor and other high refractive index semiconductor materials, and the antireflection passivation composite structure is applied to the solar cell absorption area Surface emission / reception semiconductor optoelectronic devices such as the surface of light-emitting diodes (LEDs), surface-emitting lasers, and detectors. The solar cells include crystalline Si cells, microcrystalline Si cells, amorphous Si and its multi-junction cells, copper indium gallium selenide c...

Embodiment 2

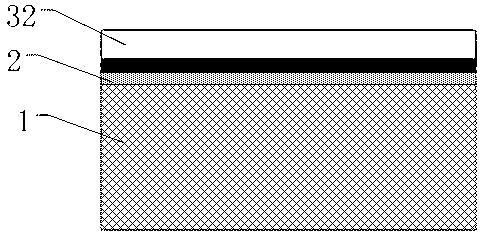

[0035] This embodiment provides a method for preparing a high-refractive index semiconductor surface anti-reflection passivation composite structure. The prepared composite structure is as follows: figure 2 The steps shown are as follows.

[0036] I. Step I is the same as Step I in Example 1.

[0037] II. Deposit metallic titanium on the dielectric film, and form a dielectric titanium oxide nanostructure 32 with a graded refractive index by means of anodic oxidation. It should be noted that: the metal deposited on the dielectric film may be a metal corresponding to a high refractive index dielectric material, at least Ti, Zr, Ta or Y, where titanium and titanium oxide are only provided as examples.

[0038] Among them, the metal titanium film can be prepared by various methods such as thermal evaporation, electron beam evaporation, magnetron sputtering, and atomic layer deposition.

[0039] The properties and functions of the resulting composite structure are as described i...

Embodiment 3

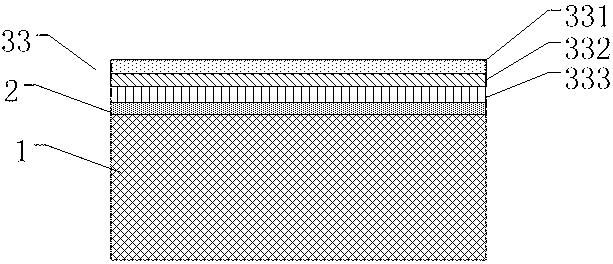

[0041] This embodiment provides a method for preparing a high-refractive index semiconductor surface anti-reflection passivation composite structure. The prepared composite structure is as follows: image 3 The steps shown are as follows.

[0042] I. Step I is the same as Step I in Example 1.

[0043] II. Depositing high-refractive-index dielectric materials with relative refractive index distributions of high, medium and low in sequence on the dielectric film to form a multi-layer composite dielectric layer with a graded refractive index. In this example, the sequentially deposited high-refractive-index dielectric materials are divided into zirconia, silicon nitride and silicon oxide thin films according to the high, medium and low relative refractive indices, forming a multi-layer composite dielectric layer 33 with a graded refractive index.

[0044] Deposit dielectric films 333, 332 and 331 in sequence on the dense dielectric film prepared in step 1, wherein 333 refers to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com