Sizing agent applied to constant SiC (Silicon Carbide) fiber and preparation method and application thereof

A sizing agent and fiber technology, which is applied in the field of sizing agent and its preparation, can solve the problems of low beam strength, decreased strength, and loose beams, etc., to improve the tensile strength of beams, improve weavability, and improve flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0035] Polyoxyethylene nonylphenol ether: OP10; brown oily liquid, produced by Sinopharm Group Chemical Co., Ltd.;

[0036] Polyvinyl alcohol: the number average molecular weight is 1750; white powder, produced by Guangzhou Chemical Reagent Factory.

Embodiment 1

[0038] The sizing agent for continuous SiC fibers in this embodiment is made of polyvinyl alcohol, modified silicone oil, polyoxyethylene nonylphenol ether, potassium persulfate, and distilled water in parts by weight of 0.15:1:0.8:0.1:100 .

[0039] Described polyvinyl alcohol is the white powder of number average molecular weight 1750;

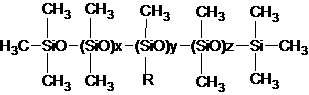

[0040] Described modified silicone oil is amino-modified silicone oil, and its molecular formula is:

[0041] ,

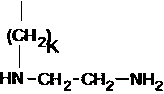

[0042] Among them, R= , K=2; (x+z=10-1000, y=1-50)

[0043] The preparation method of the sizing agent for continuous SiC fibers of this embodiment comprises the following steps:

[0044] (1) Mix 0.8 g of polyoxyethylene nonylphenol ether and 20 g of distilled water to prepare A solution;

[0045](2) Mix 0.1 g of potassium persulfate and 80 g of distilled water to prepare solution B;

[0046] (3) Heat solution A to 50°C and stir at a speed of 1200 rpm, then add 0.15 g of polyvinyl alcohol and 1 g of modified silicone oi...

Embodiment 2

[0053] The sizing agent for continuous SiC fibers in this embodiment is made of polyvinyl alcohol, modified silicone oil, polyoxyethylene nonylphenol ether, potassium persulfate, and distilled water at a weight percentage of 0.3:0.7:1.5:0.3:100.

[0054] Described polyvinyl alcohol is the white powder of number average molecular weight 1750;

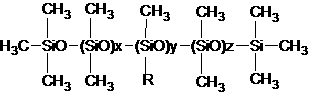

[0055] The modified silicone oil is selected from epoxy modified silicone oil, and its molecular structure is:

[0056] Among them, R= . (x+z=10-1000, y=1-50)

[0057] The preparation method of the sizing agent for continuous SiC fibers of the present invention comprises the following steps:

[0058] (1) Mix 1.5 grams of polyoxyethylene nonylphenol ether and 20 grams of distilled water to prepare A solution;

[0059] (2) Mix 0.3 grams of potassium persulfate and 80 grams of distilled water to prepare solution B;

[0060] (3) Heat solution A to 60°C and stir at 800 rpm, then add 0.3 g of polyvinyl alcohol and 0.7 g of modified sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com