Method for converting and storing solar energy with low-hydration magnesium chloride as energy storage working medium

A technology of hydrated magnesium chloride and solar energy, which is applied in chemical instruments and methods, solar thermal power generation, and mechanical power generation by solar energy, etc., can solve the problems of increasing the difficulty of operation and storage, restricting large-scale applications, and complex production processes, and achieving energy efficiency. Unbalanced supply and demand, reversible desorption/adsorption process, and large resource reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

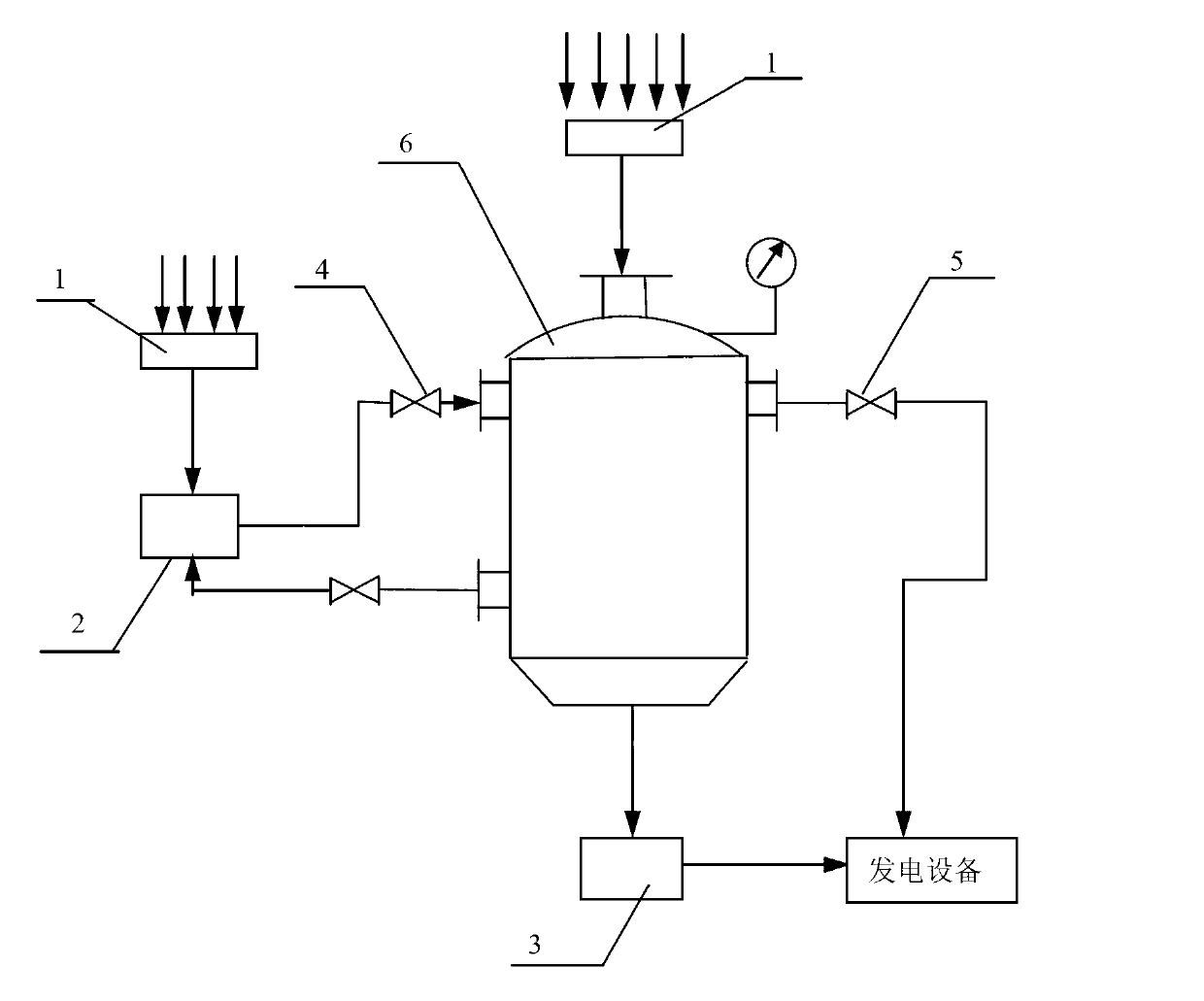

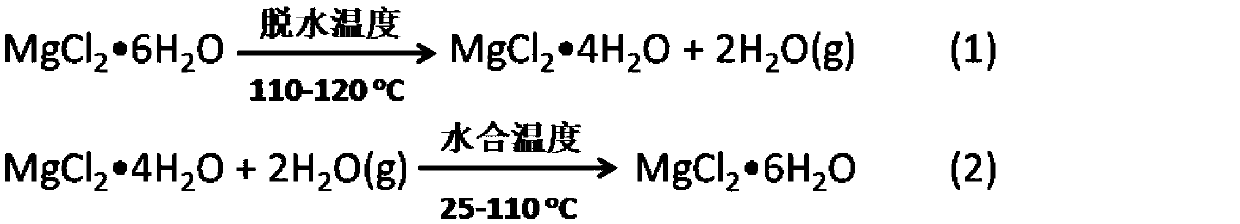

[0025]Drop into 1 kilogram of bischofite in the primary dehydration fluidized bed 6, under sunlight irradiation, use 10 square meters of flat plate solar heat collectors to heat the bischofite in the primary dehydration fluidized bed 6, and the irradiation time is 5 hours, Control the temperature in the primary dehydration fluidized bed 6 to reach 120°C. In the process, close the shut-off valve 4, open the shut-off valve 5, derive the water vapor generated by the reaction, and use the steam as power generation; when the sunlight intensity is insufficient (18 time), close the shut-off valve 5, open the shut-off valve 4, pass the water vapor in the heat preservation water tank 2 into the primary dehydration fluidized bed 6, and control the water vapor pressure in the primary dehydration fluidized bed 6 to be 1.013×10 3 Pa, the temperature is 25°C, the heat released is passed to the thermal insulation water tank 3, and the generated water vapor is used to generate electricity, whe...

Embodiment 2

[0029] Drop into 0.5 kilogram of bischofite in the primary dehydration fluidized bed 6, under sunlight irradiation, use the flat type solar heat collector of 8 square meters to heat the bischofite in the primary dehydration fluidized bed 6, the irradiation time is 2 hours, Control the temperature in the primary dehydration fluidized bed 6 to be 130°C. In the process, close the shut-off valve 4, open the shut-off valve 5, derive the water vapor generated by the reaction, and use the steam as power generation; when the sunlight intensity is not enough (19 time), close the shut-off valve 5, open the shut-off valve 4, pass the water vapor in the heat preservation water tank 2 into the primary dehydration fluidized bed 6, and control the water vapor pressure in the primary dehydration fluidized bed 6 to be 3.262×10 3 Pa, temperature is 80 DEG C, and the heat that produces passes in the insulation water tank 3, and the steam that produces is used for generating electricity, and where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com