Glucose oxidase electrode, preparation method and application thereof

A glucose oxidase and electrode technology, applied in the direction of material analysis, measuring devices, instruments, etc. by electromagnetic means, to achieve the effects of simple and fast preparation process, increased enzyme loading, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] According to the preparation method of the glucose oxidase electrode of the present invention, the template-free electrochemical method comprises: at a current density of 0.01-1 mA cm -2 , the energization time is 20 minutes to 2 hours, and the temperature of the electrolyte is 20-40°C, the conductive electrode substrate is used as the working electrode, the platinum sheet is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode. The electrolytic solution containing the conductive polymer monomer and the dopant is electrolyzed; preferably, the current density is 0.01-0.5mA·cm -2 , the power-on time is 30 minutes-1 hour, and the temperature of the electrolyte is 25-35°C.

[0022] According to the preparation method of the glucose oxidase electrode of the present invention, the preparation method of the electrolytic solution containing the conductive polymer monomer and the dopant is not particularly limited, and can be prep...

Embodiment 1

[0032] This example is used to illustrate the glucose oxidase electrode of the present invention and its preparation method.

[0033] 1) Preparation of aniline monomer electrolyte: to 20mL with a concentration of 1mol L -1 HClO 4 Add aniline monomer (Sinopharm Group Chemical Reagent Co., Ltd., analytically pure) to the aqueous solution to obtain aniline monomer concentration of 0.1mol L -1 aniline monomer electrolyte.

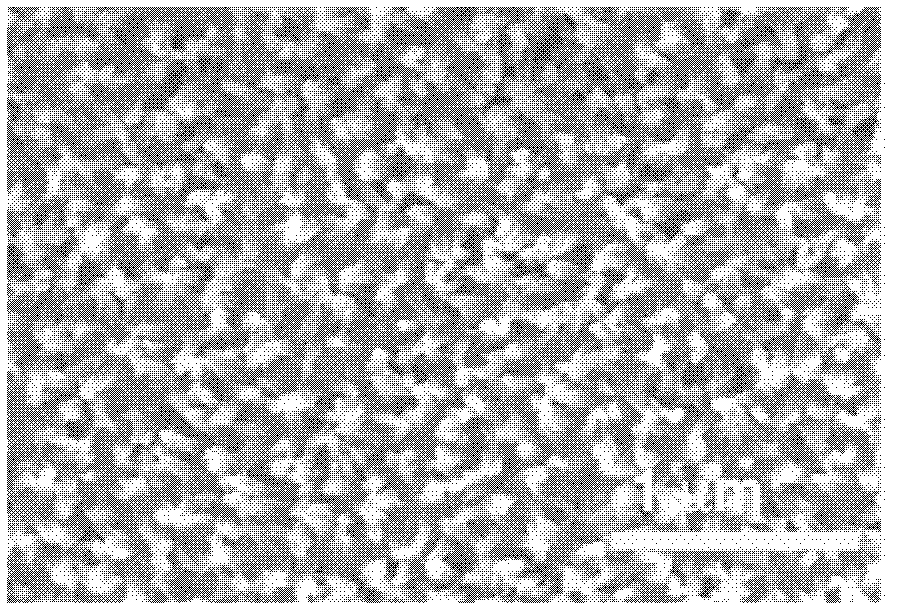

[0034] 2) Preparation of conductive polymer nanoarray electrodes: at 25°C, a polished platinum sheet (Pt) was used as the working electrode, a Pt sheet (15×20mm, 0.2mm) was used as the counter electrode, and a saturated calomel electrode was used as the The reference electrode uses the above-mentioned aniline monomer electrolyte as the electrolyte, adopts the method of constant current, and the current density is 0.01mA·cm -2 , energized for 0.5 hours, a green polyaniline nanowire array was deposited on the surface of the working electrode (see figure 1 SEM...

Embodiment 2

[0039] This example is used to illustrate the glucose oxidase electrode of the present invention and its preparation method.

[0040] 1) Preparation of aniline monomer electrolyte: 0.5mol L to 20mL -1 HClO 4 Add aniline monomer (Sinopharm Group Chemical Reagent Co., Ltd., analytically pure) to the aqueous solution to obtain aniline monomer concentration of 0.5mol L -1 aniline monomer electrolyte.

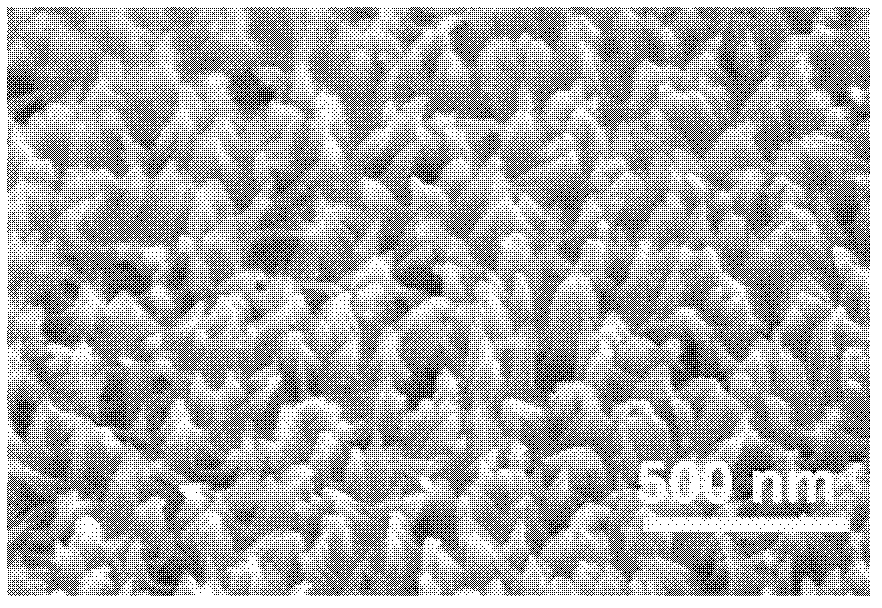

[0041] 2) Preparation of conductive polymer nanoarray electrodes: at 30°C, a polished platinum sheet (Pt) was used as the working electrode, a Pt sheet (15×20mm, 0.2mm) was used as the counter electrode, and a saturated calomel electrode was used as the The reference electrode uses the above-mentioned aniline monomer electrolyte as the electrolyte, adopts the method of constant current, and the current density is 0.1mA cm -2 , energized for 40 minutes, and deposited a layer of green polyaniline nanowire array on the surface of the working electrode. The diameter of the polyanili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com