Magnetic microsphere carrier and its making method

A technology of magnetic microspheres and carriers, applied in the field of biomaterials, can solve problems such as the reduction of reaction kinetics, and achieve the effects of regular shape, improved capacity, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

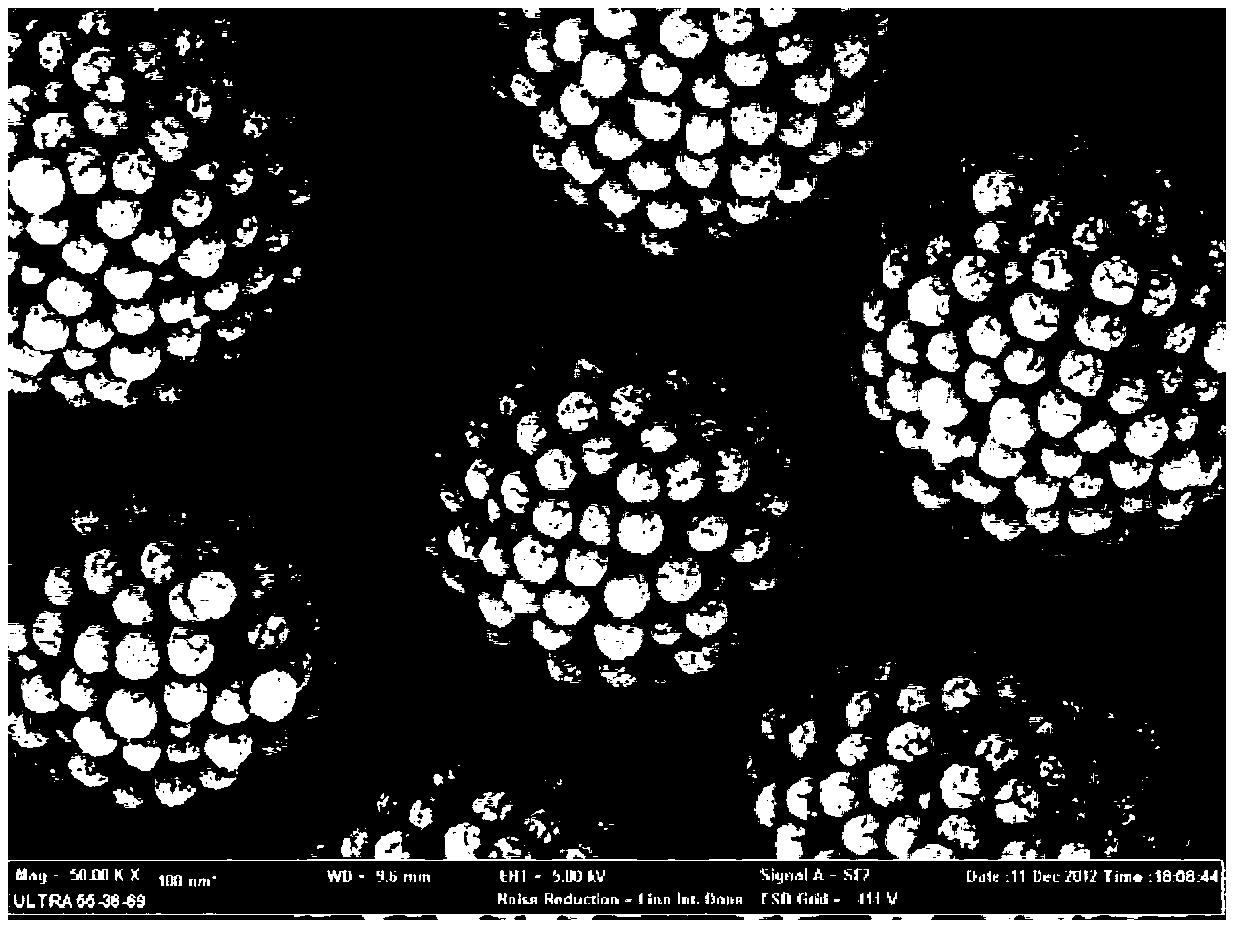

Embodiment 1

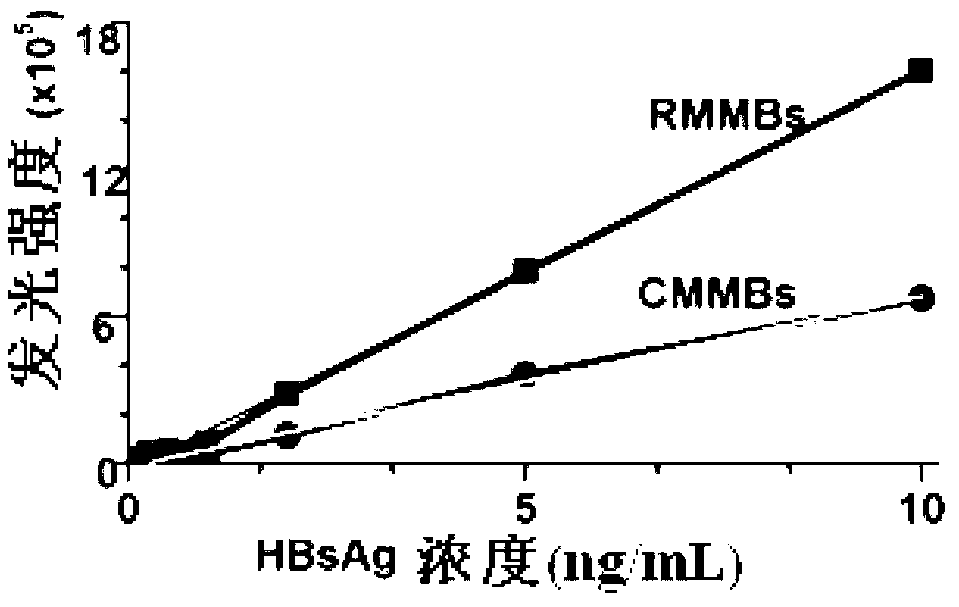

[0033] The first step is to use magnetic polymer microspheres with a particle size of 700nm as the cue ball. There are 50wt% nano-ferric oxide particles dispersed inside the cue ball. The matrix of the magnetic microspheres is polystyrene, and the surface is polystyrene. Copolymer of ethylene and polyacrylic acid. Take 80 mg of magnetic microspheres containing carboxyl groups on the surface and disperse them into 20 mL of 10 mM MES (2-(N-morpholino)ethanesulfonic acid) solution (the solution contains 0.05 wt% Tween 20). In the three-necked flask, under stirring, add EDC / NHS activator so that the final concentration of the two is 50 mg / mL. The reaction was stirred for 15 minutes, and the unreacted EDC and NHS were washed with the help of a magnetic field to obtain activated magnetic cue balls. The activated magnetic cue balls were then dispersed into 20 mL of phosphate buffer solution (pH = 7.6, containing 0.05 wt% Tween 20). Next, add the activated magnetic cue sphere disper...

Embodiment 2

[0037] In the first step and the second step of this embodiment, except that the cue ball particle size is 5 μm carboxyl magnetic microspheres, and the daughter balls are 200 nanometer amino polystyrene microspheres, the remaining operation methods are the same as in Example 1.

[0038] In the third step, the remaining steps are the same except that 15 micrograms of assembled magnetic microspheres are added to each concentration gradient. The detection limit of HBsAg obtained through detection and calculation is 1.2 ng / mL, and the detection limit of the smooth magnetic microspheres coated with the same cue ball as the surface amine silica shell is 3.1 ng / mL.

Embodiment 3

[0040] In the first step and the second step of this embodiment, except that the cue ball particle diameter is 10 μm carboxyl magnetic microspheres, and the daughter balls are 200 nm amino polystyrene microspheres, the rest of the operation method is the same as that of Example 1.

[0041] In the third step, the remaining steps are the same except that 30 micrograms of assembled magnetic microspheres are added to each concentration gradient. The detection limit of HBsAg obtained through detection and calculation is 1.5 ng / mL, and the detection limit of the smooth magnetic microspheres coated with the same cue ball as the surface amine silica shell is 3.8 ng / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com