Ginkgolide osmotic pump tablet and preparation method thereof

A technology of ginkgolide and osmotic pump tablets is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, and drug combinations, which can solve problems such as difficulty in ensuring the synchronization of traditional Chinese medicine ingredients, and achieve good in-vivo and in-vitro correlation. Solubility difference, effect of small individual differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]

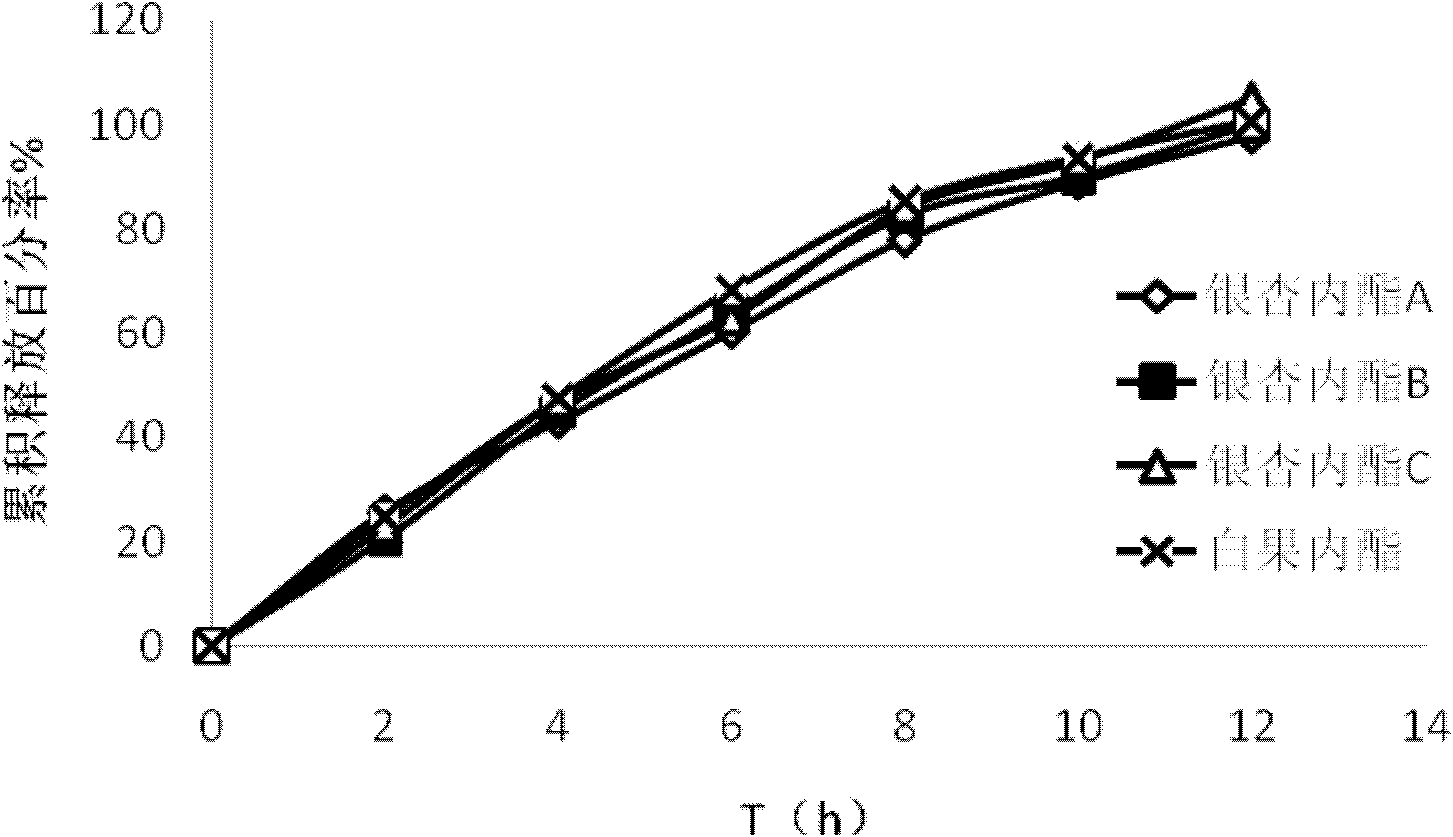

[0027] Preparation process: add prescription amount of drug and polyvinylpyrrolidone into ethanol-dichloromethane (1:1) mixed solvent, and ultrasonically dissolve it completely. Rotary evaporation, water bath temperature 60 ° C, distilled off the organic solvent. Put it in a vacuum drying oven and continue drying for 24 hours to remove the residual solvent to obtain the ginkgolide solid dispersion. Pass the prescribed amount of ginkgolide solid dispersion, microcrystalline cellulose, and talcum powder through a 60-mesh sieve, and mix evenly to form the drug-containing layer; add the prescribed amount of lactose, polyoxyethylene PEO WSR303, polyoxyethylene PEO WSR N10 and talcum powder are all passed through a 60-mesh sieve, mixed evenly, which is the booster layer. A double-layer tablet press is used to compress into tablets to obtain tablet cores. Dissolve the prescribed amount of polyethylene glycol 4000 in acetone, and then dissolve the prescribed amount of ce...

Embodiment 2

[0029]

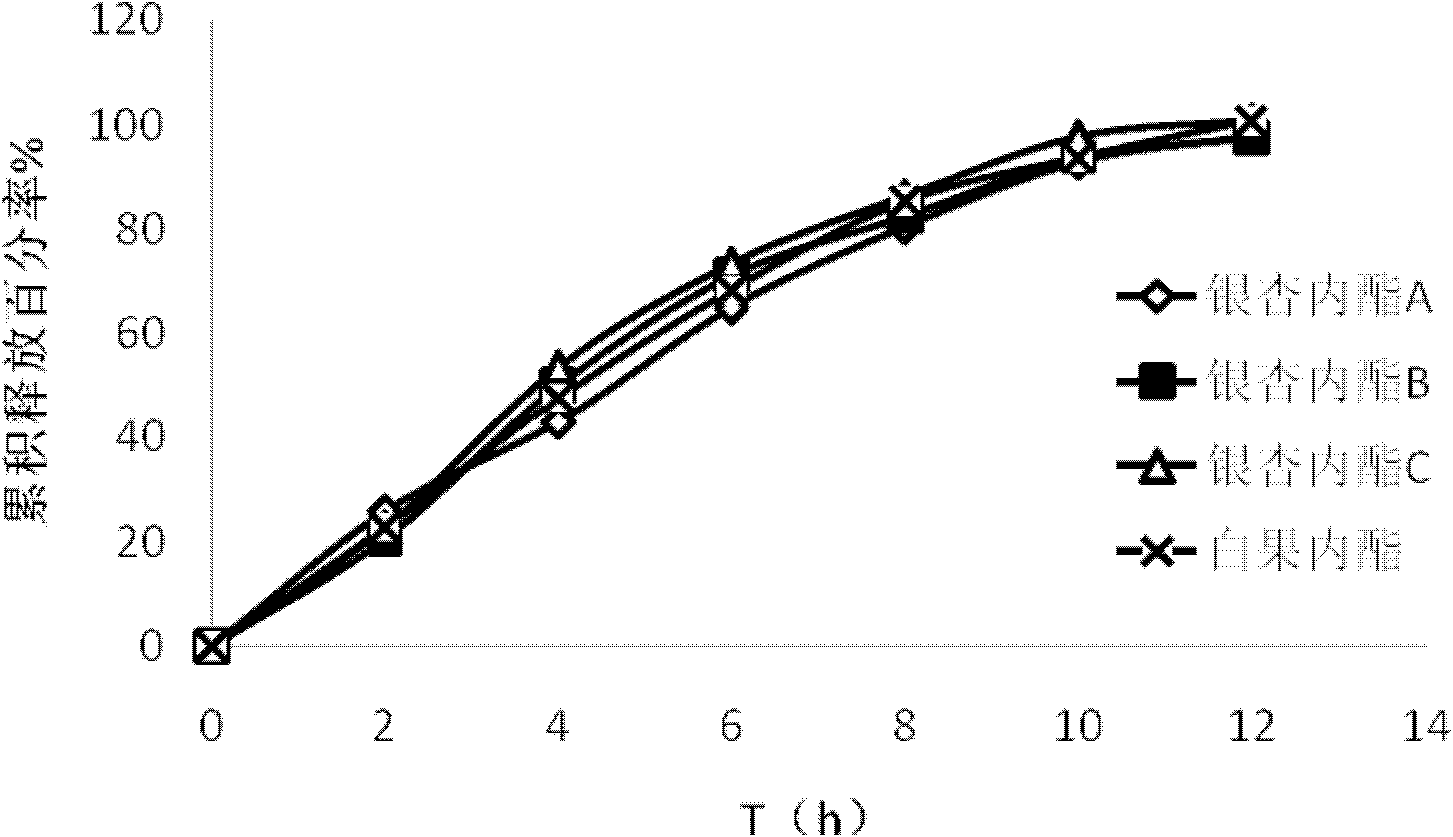

[0030]Preparation process: add the prescribed amount of drug and poloxamer into dichloromethane, and ultrasonically dissolve it completely. Rotary evaporation, water bath temperature 60 ° C, distilled off the organic solvent. Put it in a vacuum drying oven and continue drying for 30 hours to remove the residual solvent to obtain the ginkgolide solid dispersion. Pass the prescribed amount of ginkgolide solid dispersion, compressible starch, and talcum powder through a 100-mesh sieve, and mix evenly to form the drug-containing layer; pass the prescribed amount of sucrose, polyoxyethylene PEO WSR N10, and talc powder through a 100-mesh sieve. Mesh sieve, mix evenly, that is the booster layer. A double-layer tablet press is used to compress into tablets to obtain tablet cores. Dissolve the prescribed amount of polyethylene glycol 4000 in acetone, and then dissolve the prescribed amount of cellulose acetate in the solution to obtain the coating solution. The tablet c...

Embodiment 3

[0032]

[0033]

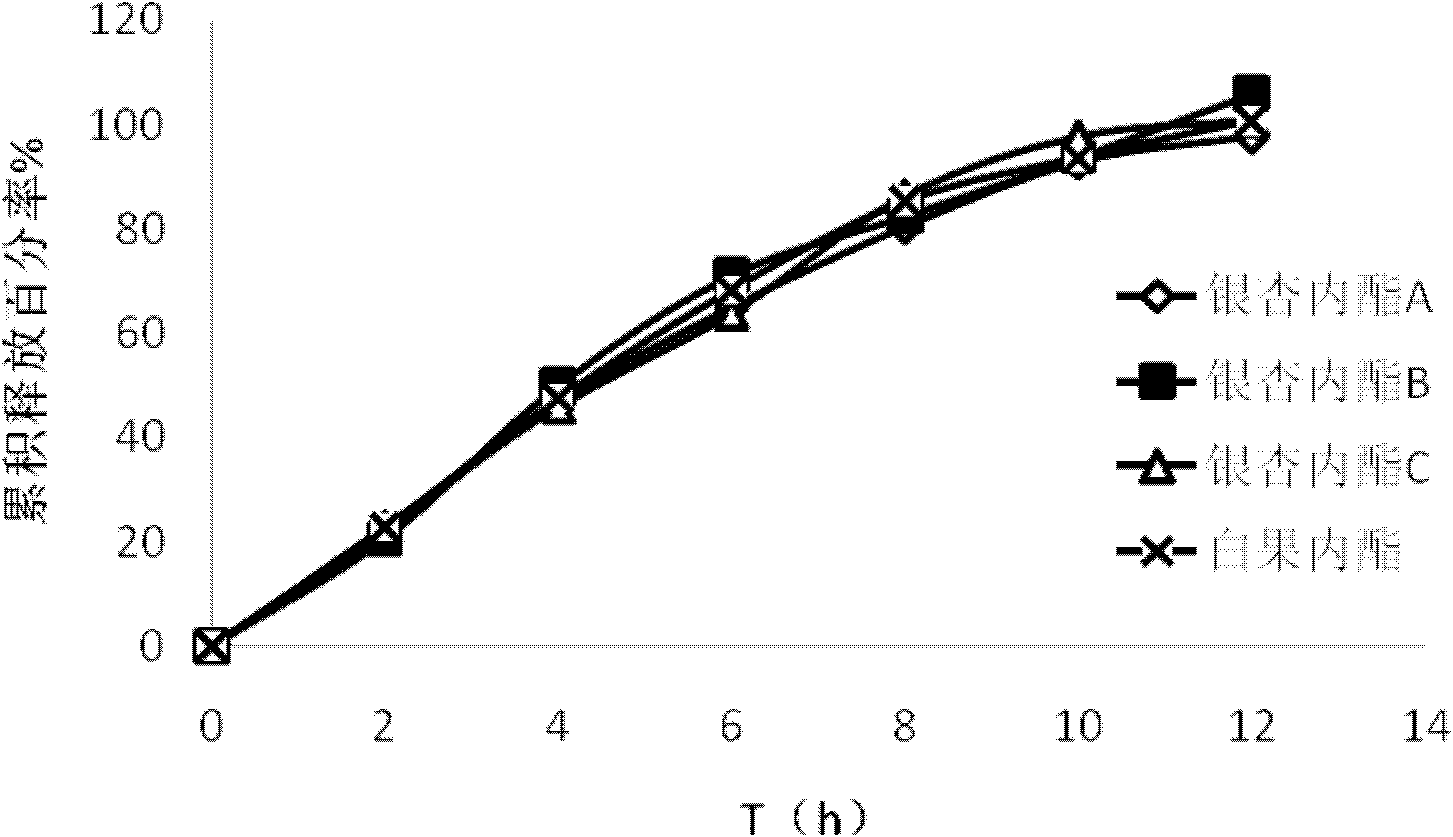

[0034] Preparation process: add the prescribed amount of medicine and polyethylene glycol 4000 into ethanol, and ultrasonically dissolve it completely. Rotary evaporation, water bath temperature 60 ° C, distilled off the organic solvent. Put it in a vacuum drying oven and continue drying for 12 hours to remove the residual solvent to obtain the ginkgolide solid dispersion. Pass the prescribed amount of ginkgolide solid dispersion, lactose, and talcum powder through a 80-mesh sieve, and mix evenly to form the drug-containing layer; pass the prescribed amount of glucose, polyoxyethylene PEO WSR303, and talc powder through a 80-mesh sieve, and mix Uniform, that is, the booster layer. A double-layer tablet press is used to compress into tablets to obtain tablet cores. Dissolve the prescribed amount of polyethylene glycol 4000 in acetone, and then dissolve the prescribed amount of cellulose acetate in the solution to obtain the coating solution. The table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com