Preparation method of three-dimensional graphene/porphyrin compounded oxygen reduction electrocatalyst

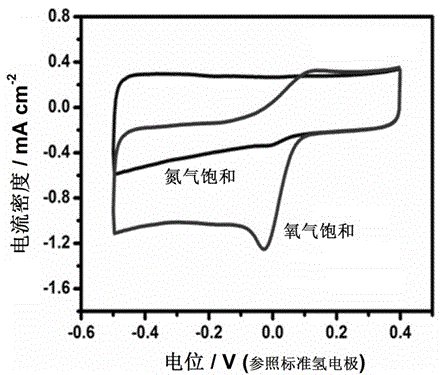

An electrocatalyst and graphene technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of platinum-based catalysts being expensive, hindering the development of fuel cells, Element doping involves harsh conditions and other issues to achieve excellent oxygen reduction catalytic performance and long-term stability, improve oxygen reduction catalytic performance, and significantly resist methanol catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

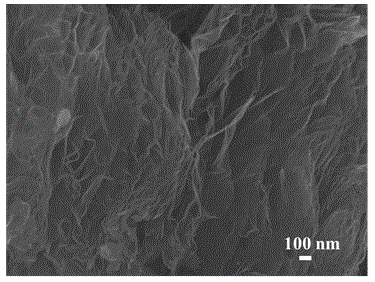

[0025] First prepare three-dimensional graphene by the following method:

[0026] a) Using concentrated sulfuric acid, sodium nitrate and potassium permanganate to oxidize graphite powder to obtain graphite oxide;

[0027] b) ultrasonically disperse the graphite oxide obtained in step a) to prepare a graphene oxide solution, then add hydrazine hydrate to the graphene oxide solution, centrifuge and clean the product after the reaction, and dry the product under vacuum to obtain graphene;

[0028] c) heat-treating the graphene obtained in step b) at 200° C. for 10 min under vacuum to obtain three-dimensional graphene.

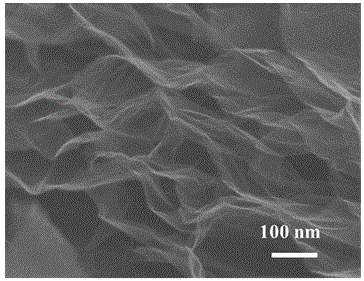

[0029] Then the three-dimensional graphene / porphyrin composite oxygen reduction electrocatalyst is prepared by the following method:

[0030] 1) Heat-treat the three-dimensional graphene at 600°C for 60 minutes;

[0031] 2) Stir and mix the three-dimensional graphene and porphyrin after the heat treatment in step 1) under liquid phase conditions at a mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com