Coating for magnesium alloy metal mold casting as well as preparation method and applications thereof

A metal mold casting, magnesium alloy technology, applied in casting molding equipment, metal processing equipment, coating and other directions, can solve the problems affecting the quality of castings, waste of magnesium alloy raw materials, etc., to save raw materials and energy consumption, easy operation, surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. The proportion of paint is as follows:

[0043]

[0044] 2. Use of paint:

[0045] Mix the paint evenly according to its ratio, and then spray the prepared paint on the preheated metal mold. The process specification is as follows:

[0046] Preheat the metal mold at 260°C and keep it warm for 2.5h;

[0047] Spray the paint, raise the temperature to 330°C, and keep it warm for 3 hours;

[0048] Ready to use.

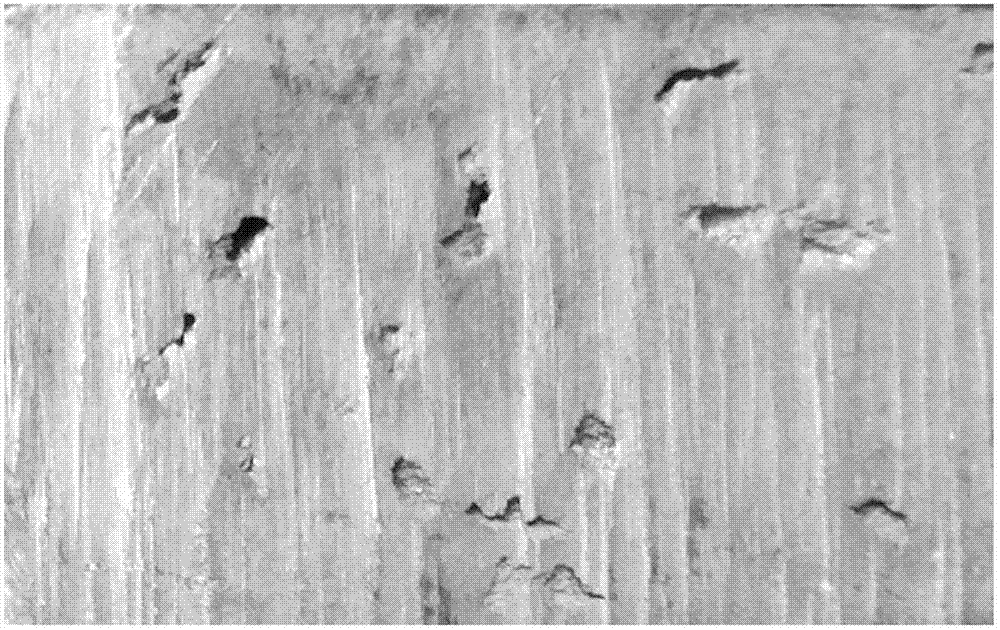

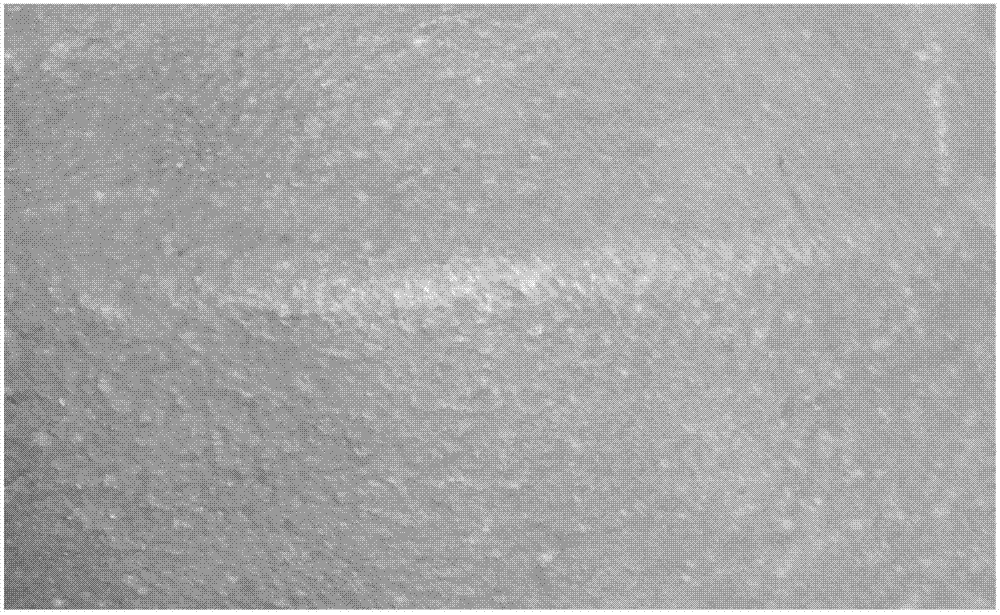

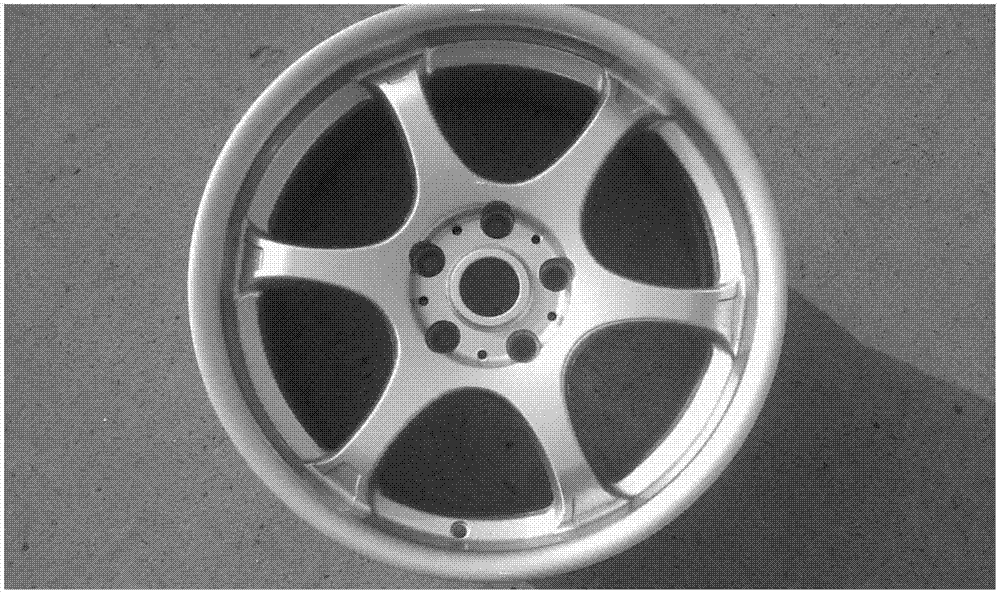

[0049] The castings produced by this coating have no reactive slag pores, the surface of the castings is smooth, and the precision is high, while the castings produced by ordinary coatings have more serious defects. The specific surface appearance is as follows Figure 1-2 shown. The produced hubs have high precision and good quality, such as Figure 3-4 shown.

Embodiment 2

[0051] 1. The proportion of paint is as follows:

[0052]

[0053] 2. Use of paint:

[0054] Mix the paint evenly according to its ratio, and then spray the prepared paint on the preheated metal mold. The process specification is as follows:

[0055] Preheat the metal mold at 250°C and keep it warm for 4 hours;

[0056] Spray the paint, raise the temperature to 350°C, and keep it warm for 2 hours;

[0057] Ready to use.

[0058] The castings produced by this coating have no reactive slag pores, the surface of the castings is smooth, the precision is high, and the surface appearance is as follows: figure 2 As shown; and the produced hub has high precision and good quality.

Embodiment 3

[0060] 1. The proportion of paint is as follows:

[0061]

[0062]

[0063] 2. Use of paint:

[0064] Mix the paint evenly according to its ratio, and then spray the prepared paint on the preheated metal mold. The process specification is as follows:

[0065] Preheat the metal mold at 280°C and keep it warm for 2 hours;

[0066] Spray the paint, heat up to 300°C, and keep it warm for 3 hours;

[0067] Ready to use.

[0068] The castings produced by this coating have no reactive slag pores, the surface of the castings is smooth, the precision is high, and the surface appearance is as follows: figure 2 As shown; and the produced hub has high precision and good quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com