A kind of preparation method and application of nano niobium pentoxide/fto electrode material

A technology of niobium pentoxide and electrode material, which is used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., to achieve the effects of easy mass production, environmental protection, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Cut the FTO substrate into small pieces with a width and length of 1.5 cm × 2 cm, and then place them in acetone solution, ethanol solution, and deionized water in turn, and ultrasonically treat each for 15 minutes; after treatment, place in a vacuum drying oven Dry in medium and set aside.

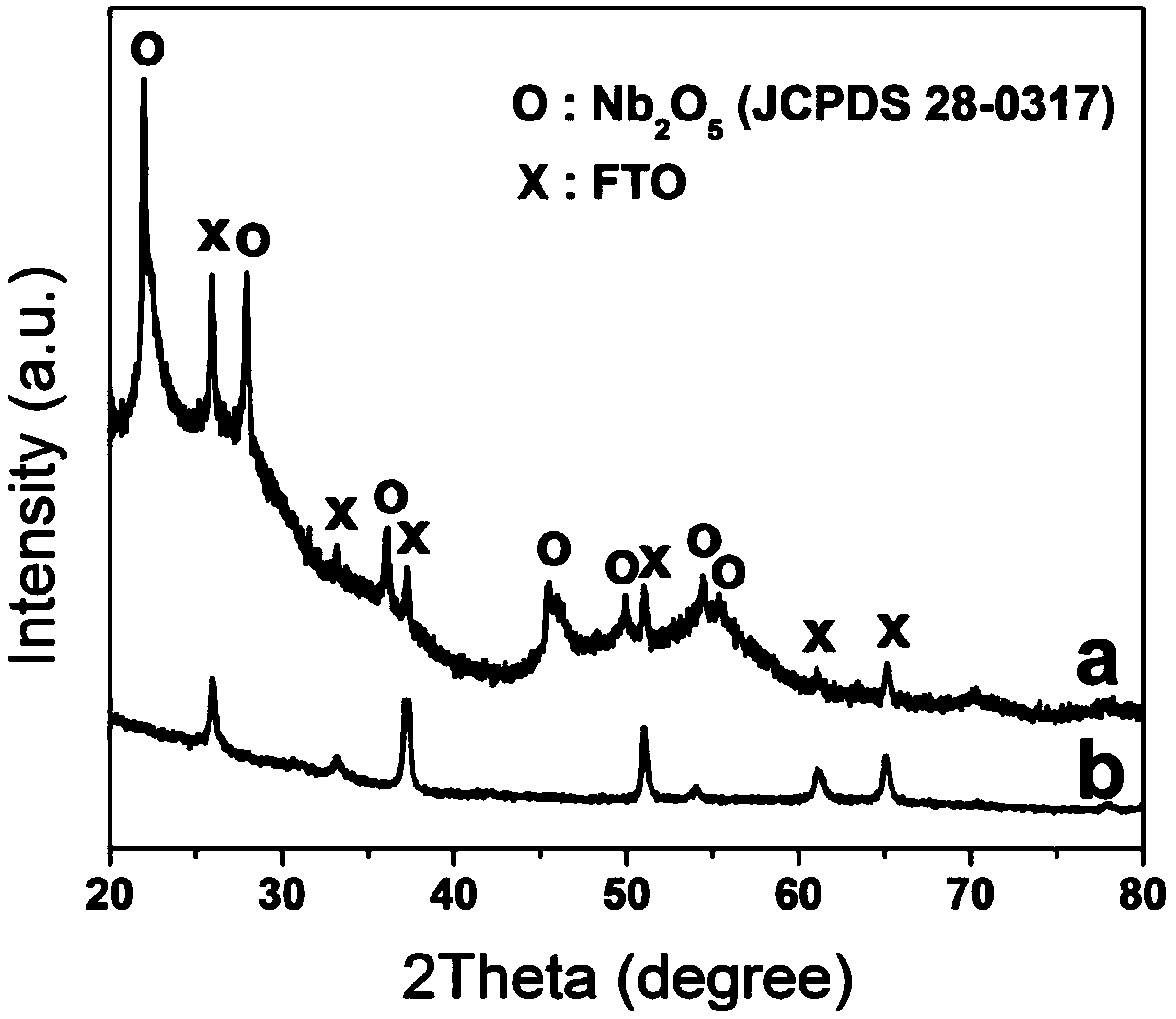

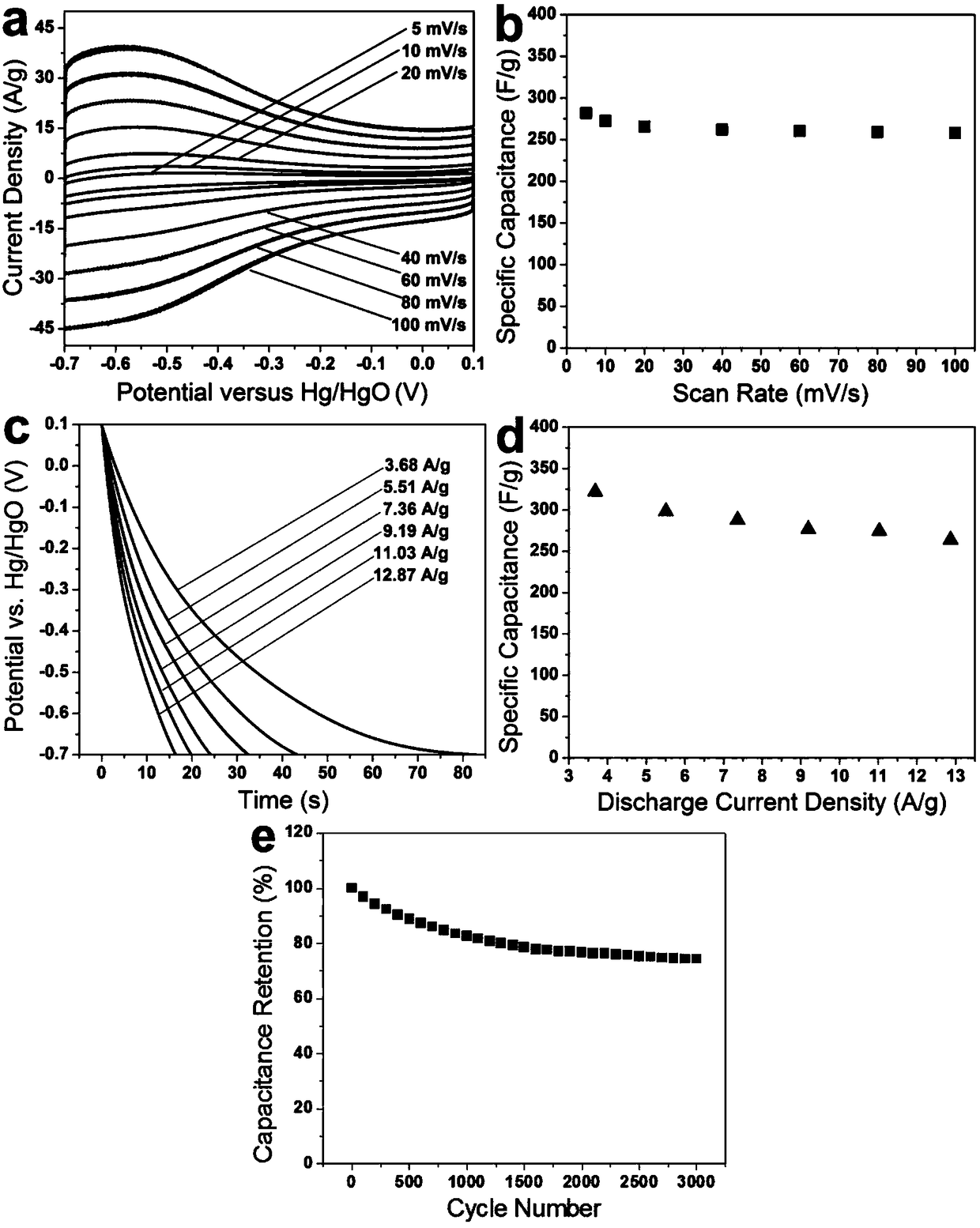

[0028] Add 1.5mmol of niobium pentachloride and 7.5mmol of sodium acetate powder to 40mL of deionized water, put it in a 100ml beaker, put it in an ultrasonic instrument for 10 minutes to make it evenly mixed, and then pour it into a 50mL polytetrafluoroethylene liner In the reaction kettle at the bottom, put a piece of pretreated FTO substrate into the above reaction kettle with the conductive side up, seal it, place it in an oven, control the temperature of the oven at 200°C, and react for 8 hours. Cool to room temperature, take out the FTO substrate, wash it, and dry it in vacuum to obtain the nanometer niobium pentoxide / FTO water-based supercapacitor electrode material.

[002...

Embodiment 2

[0032] The pretreatment mode of FTO substrate is the same as embodiment 1.

[0033] Add 1.5mmol of niobium nitrate and 7.5mmol of sodium acetate powder to 40mL of deionized water, put it in a 100ml beaker, put it in an ultrasonic instrument for 10 minutes to make it evenly mixed, and then pour it into a 50mL polytetrafluoroethylene substrate In the reaction kettle, put a piece of pretreated FTO substrate into the above reaction kettle with the conductive side up, seal it, place it in an oven, control the temperature of the oven at 180°C, and react for 12 hours. At room temperature, take out the FTO substrate, wash it several times, and dry it in vacuum to obtain the electrode material of nanometer niobium pentoxide / FTO water-based supercapacitor.

[0034] The FTO substrate made of the FTO conductive glass in the present invention can be used not only as a substrate but also as a current collector for electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com