Magnéli phase titanium oxide nanowire array and preparation method thereof

A nanowire array, phase titanium oxide technology, applied in titanium dioxide, titanium oxide/hydroxide, nanotechnology and other directions, can solve problems such as inability to effectively utilize natural light, and achieve high practical value, novel synthesis methods, and rich raw material sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

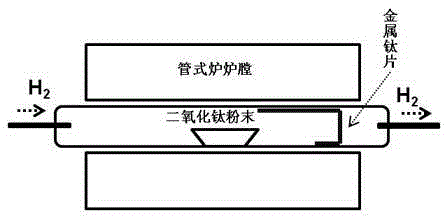

[0024] (1) if figure 1 As mentioned above, take the length and width as 2×6cm 2 Titanium sheet folded into figure 1 The shape shown was ultrasonically cleaned with acetone for 30 minutes, then ultrasonically cleaned with deionized water, and then etched with a mixed acid solution of hydrofluoric acid: nitric acid: deionized water with a volume ratio of 1:3:6 for one minute, and finally Ultrasonic cleaning and drying with deionized water to obtain titanium metal sheets with clean surfaces;

[0025] (2) Put the corundum boat containing 2 grams of titanium dioxide powder and the metal titanium sheet etched in step (1) into the tube furnace together, and place it as figure 1 shown;

[0026] (3) Pre-flow nitrogen for 2 hours at a nitrogen flow rate of 100mL / min, turn off the nitrogen gas, and pass hydrogen gas for 30 minutes at a hydrogen flow rate of 100mL / min. Then, adjust the hydrogen flow rate to 50mL / min, raise the temperature to 1050°C at a rate of 8°C / min, keep it war...

Embodiment 2

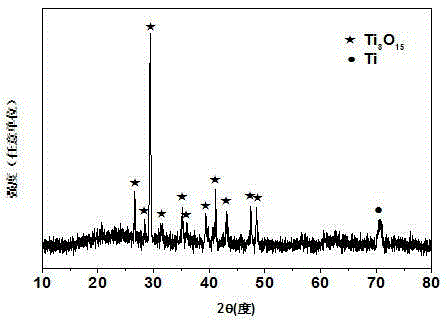

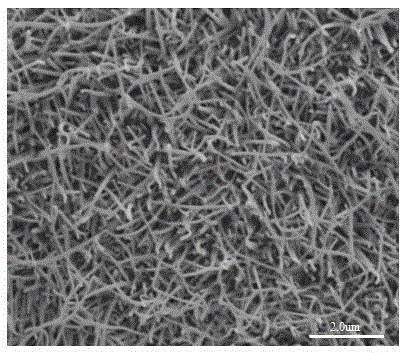

[0030] The difference between this example and Example 1 is that 10% oxalic acid solution is used and etched at 100°C for 2 hours. The other steps are the same as in Example 1. The obtained Magnéli phase titanium oxide nanowire is similar to the product of Example 1. Its XRD pattern and scan Electron microscope pictures can refer to figure 2 , image 3 .

Embodiment 3

[0032] The difference between this example and Example 1 is that the hydrogen flow rate is adjusted to 20mL / min during heat preservation, and the other steps are the same as in Example 1. The obtained Magnéli phase titanium oxide nanowires have a morphology similar to that of the product in Example 1, and the diameter ratio is slightly smaller than that of the product in Example 1. Nanowire, its XRD diagram and scanning electron microscope diagram can refer to figure 2 , image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com