Anti-emptying self-compacting roadbed structure and construction method

A construction method and compact technology, applied in the field of self-compacting roadbed structure and construction, can solve the problems of environmental sustainability violation, affecting driving comfort, and consuming equipment and manpower, and achieve short-term and long-term service performance. The effect of seepage prevention and hollowing out and reducing soil permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

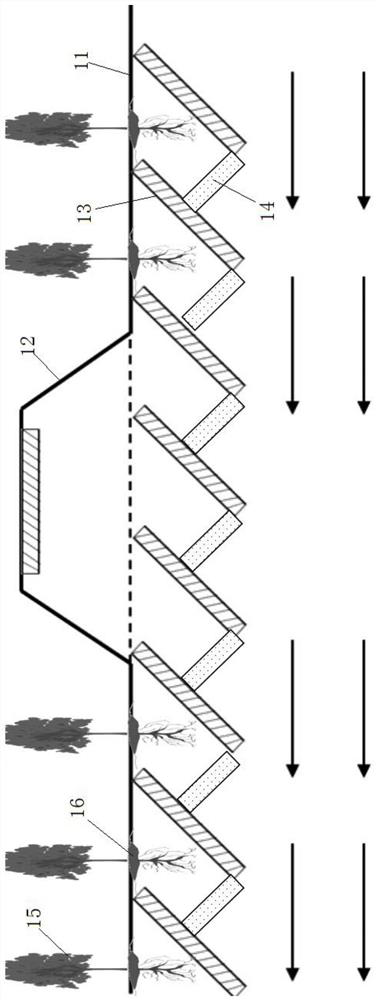

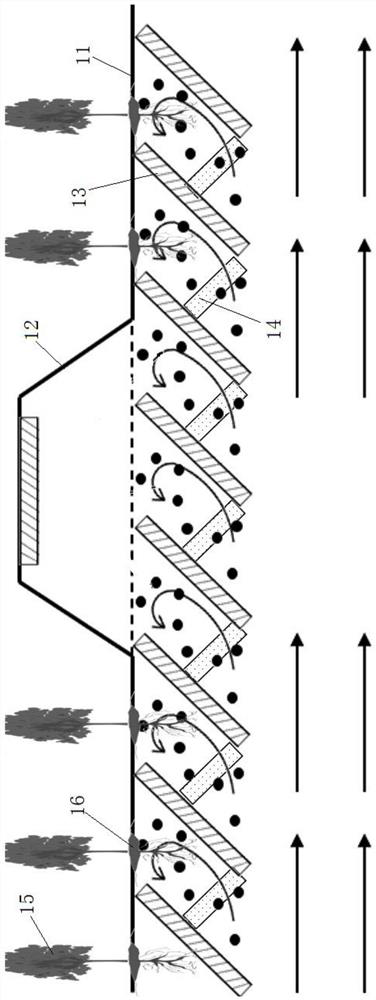

[0032] Embodiment one, with reference to Figure 1-Figure 2 As shown, the present invention is an anti-hollowing self-compacting roadbed structure, including: the original foundation 11 and the filling roadbed 12 arranged on the original foundation 11;

[0033] The bottom of the filled subgrade 12 and the original foundation 11 on both sides are provided with multi-layer deflectors 13 inserted obliquely. According to the actual situation, for example, if the water velocity under the original foundation 11 is different, the setting angle of the deflector 13 will also be different, and the deflector 13 is usually made of a polymer material plate, which has good strength and corrosion resistance. 13 is used to block the erosion of the original foundation 11 by the tidal high tide water flow, and intercept and accumulate the sediment particles in the tidal ebb and flow flow to tamp the original foundation 11. The tide flow direction in the original foundation 11 is the same. It c...

Embodiment 2

[0041] Embodiment two, refer to Figure 1-Figure 4 As shown, a kind of construction method of the self-compacting subgrade structure of a kind of anti-hollowing as described in embodiment one, this construction method comprises the following steps:

[0042] 1. The surface treatment of the original foundation 11 to be built to fill the subgrade 12 is smooth, so as to facilitate the subsequent construction of the plug-in board and the construction of the filled subgrade 12;

[0043] 2. On the side of the original foundation 11 close to the water area, insert the first layer of deflector 13 according to the set inclination angle and insertion depth through the plug-in machine; usually, the insertion depth of the deflector 13 needs to reach or be close to the roadbed work area or Apply Diffusion to the lower part of the area of influence.

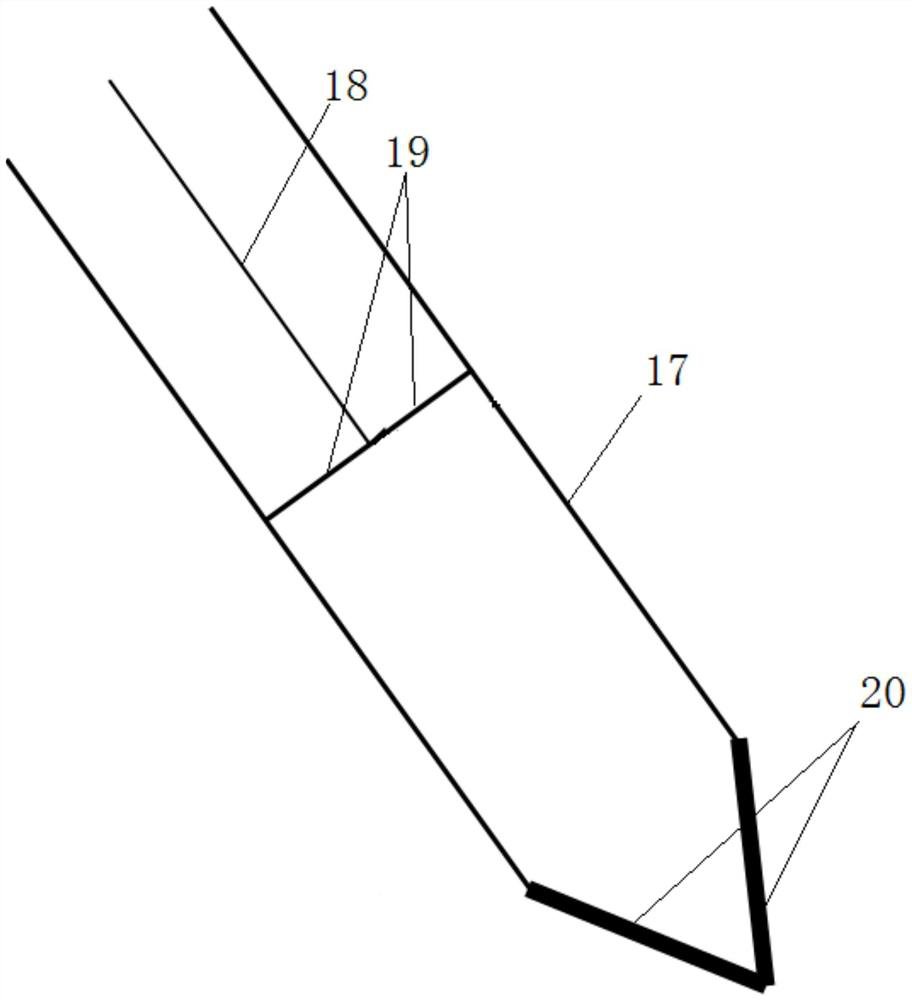

[0044] 3. Fill the loofah in the metal mold box 17 of the set size, insert the metal mold box 17 filled with the loofah at the designated p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com