Ultrahigh-performance concrete reinforced channel girder deck structure and reinforcing method thereof

A concrete reinforcement and ultra-high performance technology, which is applied in bridge reinforcement, bridge, bridge construction, etc., can solve the problems of long curing time in high temperature steam, difficulty in guaranteeing durability, and inconvenient transportation, so as to ensure durability and increase the rigidity of the whole section , the effect of preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example is the preparation process of the ultra-high performance concrete used in the present invention.

[0040] Concrete per cubic meter is composed of the following raw materials: cement 800-1200kg, mineral admixture 50-200kg, fine aggregate 800-1200kg, steel fiber 78-300kg, water reducer (solid content) 3-15kg, defoamer 0.6-5kg, expansion agent 60-120kg, water 105-250kg.

[0041] In a specific operation process, each cubic ultra-high performance concrete includes the following raw materials and quality: Portland cement 765kg; active SiO 2 72kg; CaO48kg; SO 3 22.5kg; Al 2 o 3 7.5kg; quartz sand 300kg; river sand 300kg; slag 400kg; steel fiber 128kg; naphthalene superplasticizer 9kg; silicone defoamer 2kg; calcium oxide expansion agent 75kg; water 200kg.

[0042] Among them, the length of steel fiber is 15-20mm, the diameter is 0.15-0.25mm, and the particle size of quartz sand, river sand and slag is all less than or equal to 5mm.

[0043] The ultra-high pe...

Embodiment 2

[0046] This embodiment is a channel beam bridge deck structure reinforced by the ultra-high performance concrete prepared in Embodiment 1.

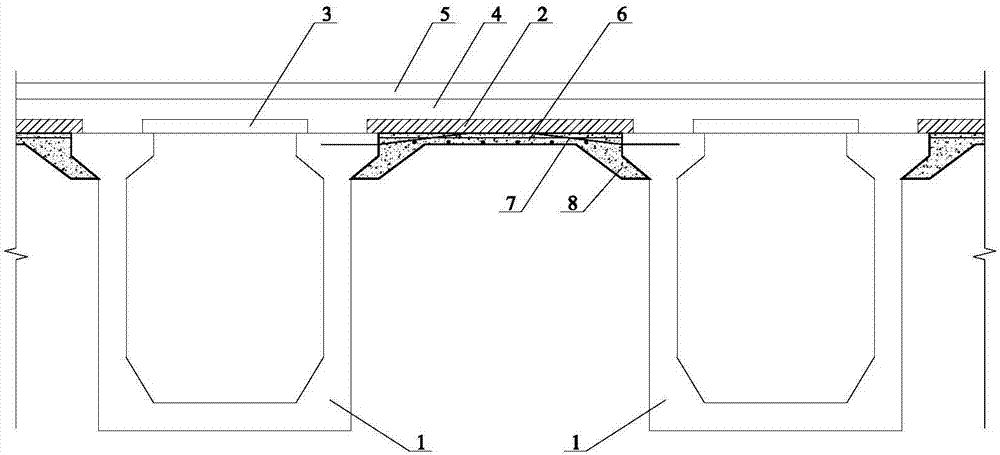

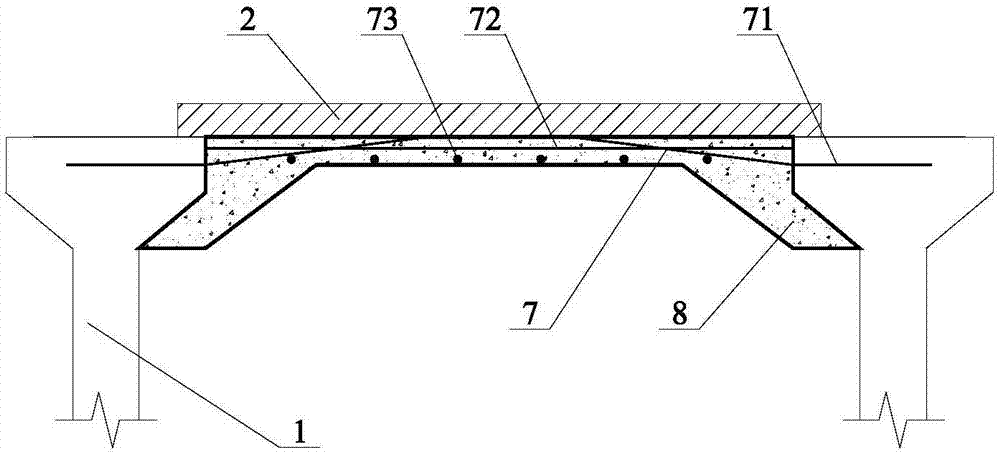

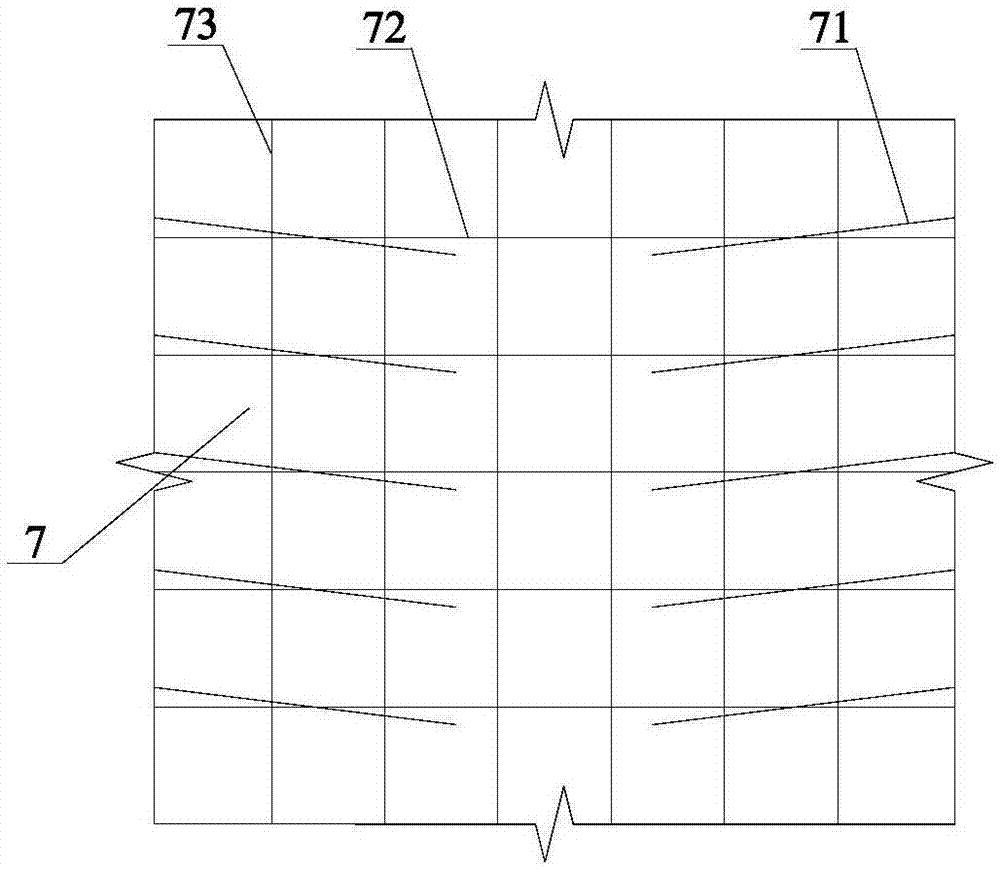

[0047] Such as figure 1 As shown, the ultra-high performance concrete reinforced channel beam deck structure of the present invention includes channel beams 1, a bridge deck 2 erected between the channel beams 1, and a bridge deck erected above the channel beams 1. Type B bridge deck 3 and the concrete pavement layer 4 and asphalt layer 5 laid on the top of the Type A bridge deck 2 and the Type B bridge deck 3, which also includes an ultra-high performance concrete reinforcement layer at the bottom of the Type A bridge deck 2 6; the ultra-high-performance concrete reinforcement layer 6 includes a steel bar structure 7 connected to the channel beam 1 and an ultra-high-performance concrete layer 8 cast in the steel bar structure 7, and the side shape of the ultra-high-performance concrete reinforcement layer 6 It is π-shaped with thicker s...

Embodiment 3

[0053] This embodiment is the reinforcement method of the channel beam bridge deck structure reinforced by ultra-high performance concrete described in Embodiment 2. The specific steps are as follows: during construction, the original concrete layer at the bottom of the A-type bridge deck is first surface-treated to remove the A-type bridge deck. For the broken and loose concrete on the surface of the Type A bridge deck, after the surface treatment, the debris and powder are thoroughly washed, and the thickness of the removed original concrete layer is about 2-5cm; For rust treatment, first use a wire brush, sand plate, sackcloth, etc. to gently wipe off the rust, and then use a steel bar rust remover to dissolve and remove the rust; The depth of the inserted steel bar in the channel beam is 18 times or 20 times the diameter of the implanted steel bar; use the implanted steel bar to erect the steel mesh, and weld or bind the thin steel bars between the steel bars; The formwork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com