Process for extracting potassium chloride by coarse flotation of primary sylvine ores

A technology of potassium halite and potassium chloride, which is applied in the technical field of extracting potassium chloride by coarse-grained flotation of primary potash halite, which can solve the problem of small grinding machine processing capacity, small flotation feed particle size, and product Filter high moisture and other problems to achieve the effect of easy large-scale industrial production, low energy consumption and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

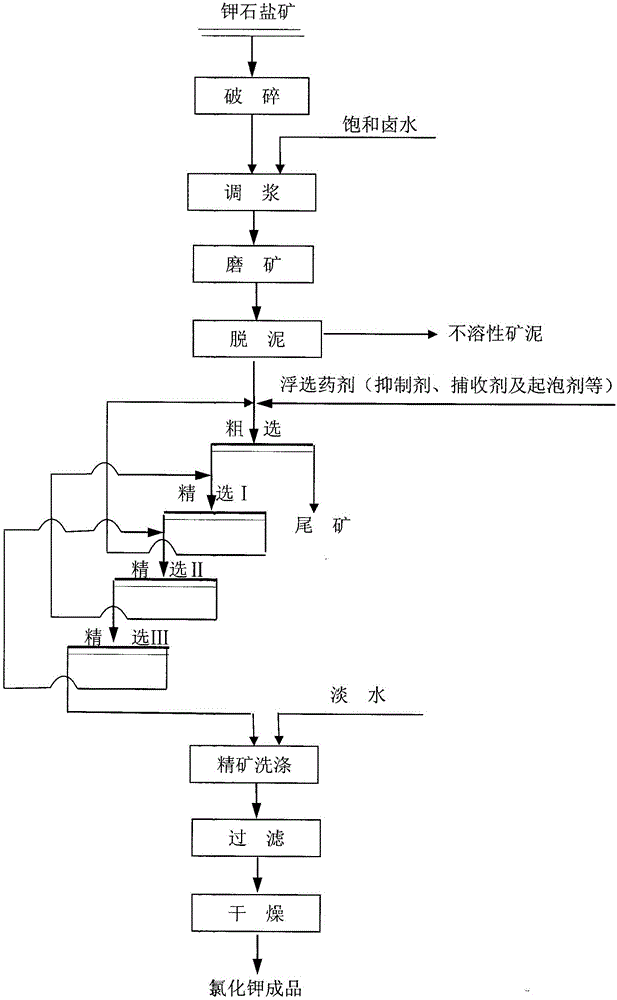

[0017] Embodiment 1, with reference to figure 1 , a technique for extracting Potassium Chloride by coarse-grained flotation of primary potash halite, the steps of which are as follows:

[0018] ⑴ Crushing: Crushing the solid potash salt ore to a particle size below 10mm;

[0019] (2) Grinding: add the material obtained in step (1) into potassium rock salt saturated brine and then send it to a rod mill for coarse grinding, control the grinding mass concentration to 50%~60%, and the grinding particle size to 1-2mm;

[0020] (3) Desliming: send the material obtained in step (2) into the desliming equipment for desliming and remove insoluble slime;

[0021] (4) Flotation: add the deslimed material obtained in step (3) into potassium rock salt saturated brine, adjust the pulp to 20%~30% ore pulp mass concentration, send it to the coarse material flotation machine for flotation, and add the ore slime successively in the rough selection Inhibitors, potassium chloride collectors, au...

Embodiment 2

[0025] Example 2, a process experiment for extracting potassium chloride by coarse-grained flotation of primary potassium halite ore: (1) crushing potassium halite (containing KCl 31.93%, insolubles 3.5%) to below 10mm, (2) crushing Finally, the raw ore is slurried with saturated brine to a concentration of 50%, and sent to a rod mill for grinding to a thickness below 1.0mm; (3) The ore pulp after grinding is sent to a hydrocyclone for desliming to remove insoluble slime. (4) Send the deslimed ore pulp to the special flotation machine for coarse grain flotation for flotation, control the concentration of the ore pulp to 25%, and add collector octadecyl primary amine 50g / t, auxiliary collector Catalytic diesel oil 20 g / t, slime inhibitor starch 200 g / t, foaming agent terpineol oil 25 g / t, after a rough separation and three separations to obtain the flotation concentrate; (5) Add the flotation concentrate to other Wash the concentrate with 12% water; (6) filter and dry the washe...

Embodiment 3

[0026] Example 3, a process experiment for extracting potassium chloride by coarse-grained flotation of primary potassium halite ore: (1) crushing potassium halite (containing KCl 26.5%, insolubles 4.20%) to below 10 mm, (2) crushing Finally, the raw ore is slurried with saturated brine to a concentration of 60%, and sent to a rod mill for grinding to a thickness below 1.2mm; (3) The ore pulp after grinding is sent to a hydrocyclone for desliming to remove insoluble slime. ⑷ Send the deslimed ore pulp to a special flotation machine for coarse-grain flotation for flotation, control the concentration of the ore pulp to 20%, and add collector octadecyl primary amine 40g / t, auxiliary collector catalyst Diesel oil 30 g / t, slime inhibitor starch 300 g / t, foaming agent terpineol oil 15 g / t, after a rough separation and three separations to obtain flotation concentrates; (5) Add flotation concentrates to its mass 18% water for concentrate washing; (6) Filter and dry the washed concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com