Textile continuous cold-batch pretreatment method, auxiliary used for method and preparation method of auxiliary

A technology for textiles and auxiliaries, which is applied in the field of continuous cold stacking of textiles, can solve the problems of insufficient washing power of cold stacks, insufficient wool efficiency and whiteness to meet dyeing requirements, and is not suitable for continuous production of large quantities, and saves energy. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Cotton 20 S ×16 S / 128×60

[0057] (1) The present invention's continuous cold reactor pretreatment method:

[0058] Working fluid prescription: LYM-A dosage: 10g / l, LYM-B dosage: 10g / l, sodium hydroxide (100% discount) dosage: 25g / l, hydrogen peroxide (100% discount) dosage: 20g / l;

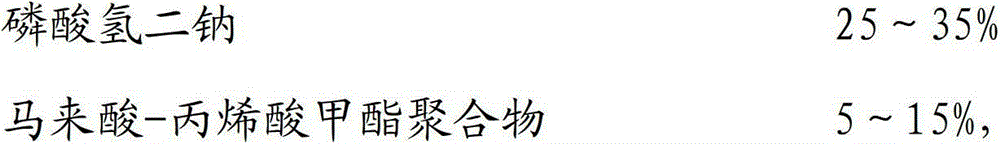

[0059] LYM-A formula: oxidant 15%, acyl compound 10%, composite catalyst 35%, disodium hydrogen phosphate 30%, maleic acid-methyl acrylate polymer 10%;

[0060] LYM-B formula: emulsifier 15%, penetrant 5%, solvent 15%, alcohol ether sulfate 15%, defoamer 1%, demineralized water 49%;

[0061] Process: gray cloth→turning cloth→sewing, hemming→singeing, one front and one reverse, speed 100 m / min, 1% light alkaline water to extinguish the fire, wet cloth→wet cloth in the cloth falling car for 20 minutes, and cover with plastic film Sealing → 85 ℃ water washing two compartments, cold water one compartment → heavy rolling car, cloth surface water retention rate 60% → padding work...

Embodiment 2

[0068] Example 2: Cotton 40 S ×40 S / 133×72

[0069] (1) Continuous cold stack process of the present invention:

[0070] Working fluid prescription: LYM-A dosage: 10g / l, LYM-B dosage: 20g / l, sodium hydroxide (100% discount) dosage: 20g / l, hydrogen peroxide (100% discount) dosage: 20g / l;

[0071] LYM-A formula: oxidant 15%, acyl compound 10%, composite catalyst 35%, disodium hydrogen phosphate 30%, maleic acid-methyl acrylate polymer 10%;

[0072] LYM-B formula: emulsifier 15%, penetrant 5%, solvent 15%, alcohol ether sulfate 15%, defoamer 1%, demineralized water 49%;

[0073] Process: gray cloth→turning cloth→sewing, hemming→singeing, one positive and one reverse, vehicle speed 110 m / min, 1% light alkaline water to extinguish fire, wet falling cloth → wet cloth placed on the cloth falling car for 20 minutes, and covered with plastic film Sealing → 85 ℃ water washing two compartments, cold water one compartment → heavy rolling car, cloth surface water retention rate 60% →...

Embodiment 3

[0080] Embodiment 3: polyester cotton 24 S ×24 S / 100×47 (T / C65 / 35)

[0081] ⑴Continuous cold stack process:

[0082] Working fluid prescription: LYM-A1 dosage: 5g / l, LYM-B dosage: 8g / l, sodium hydroxide (100% discount) dosage: 15g / l, hydrogen peroxide (100% discount) dosage: 25g / l;

[0083] LYM-A formula: 20% oxidant, 10% acyl compound, 40% composite catalyst, 25% disodium hydrogen phosphate, 5% maleic acid-methyl acrylate polymer;

[0084] LYM-B formula: emulsifier 20%, penetrant 5%, solvent 15%, alcohol ether sulfate 10%, defoamer 1%, demineralized water 49%;

[0085]Process: gray cloth→turning cloth→sew head, hemming→singeing, one positive and one reverse, speed 120 m / min, fire spraying steam, dry falling cloth→ padding working liquid, multiple dipping and multiple rolling, high liquid supply, belt Liquid rate is 110% → double-layer crawler box, vehicle speed 60 m / min, stacked at 35°C for 90 minutes → wash five compartments at 95°C → wash one compartment at 80°C → was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com