Device and method for testing electric conductivity of powder material and impedance of membrane electrode

A technology for testing devices and powder materials, applied in the direction of measuring resistance/reactance/impedance, measuring devices, measuring electrical variables, etc., can solve the problems of reducing the contact resistance between the compact and the wire, high test cost, high test accuracy, etc., to achieve Inexpensive, easy to master, and simple to test for effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Grind the ATO powder material with electronic conductivity, obtain a certain particle size powder conductive material with a 200-mesh sieve, weigh 0.5 g, dry it in a vacuum oven at 80 °C for 12 h, and briquette.

[0041] Then, the dried ATO powder material was placed in a commercial briquetting machine to prepare briquettes with a diameter of 10 mm, and the thickness of the briquettes was measured by a vernier caliper.

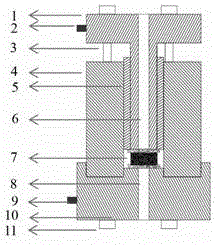

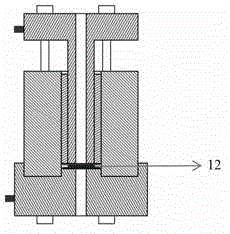

[0042] Take out the briquetting block, press the porous stainless steel mesh-briquetting block 7-stainless steel mesh figure 2 After assembly, obtain the test sample of the sandwich structure. like Figure 1a As shown, it is placed in the sample chamber to be tested consisting of the upper pressing rod 1, the base 10 and the temperature control sleeve 4, and the pressing block 7 is compressed by the upper fastening screw 2 and the lower fastening screw 11, each screw The torque is 1 N m.

[0043] The test temperature of the sample chamber can be con...

Embodiment 2

[0048] The test material was changed to ATO-SnP with both electronic and proton conductivity 2 o 7 Mix the charged powder materials, grind the powder materials, use a 200-mesh sieve to obtain powder materials with a certain particle size, weigh 0.5 g, and dry them in a vacuum oven at 80 °C for 12 h before briquetting.

[0049] Dry ATO-SnP 2 o 7 The powder material was placed in a commercial briquetting machine to prepare briquettes, the diameter of the briquettes was 10 mm, and the thickness of the briquettes was measured by a vernier caliper.

[0050] Take out the briquetting block, press the porous stainless steel mesh-briquetting block-stainless steel mesh figure 2 After assembly, obtain the test sample of the sandwich structure. like Figure 1a As shown, it is placed in the sample chamber composed of the upper pressing rod 1, the base 10 and the temperature control sleeve 4, and the pressing block 7 is compressed by the upper fastening screw 2 and the lower fastening...

Embodiment 3

[0060] This example institute, adopts catalyst IrO 2 / ATO, IrO 2 / Cs 1.5 HWA–ATO prepared membrane electrode, the specific method is as follows:

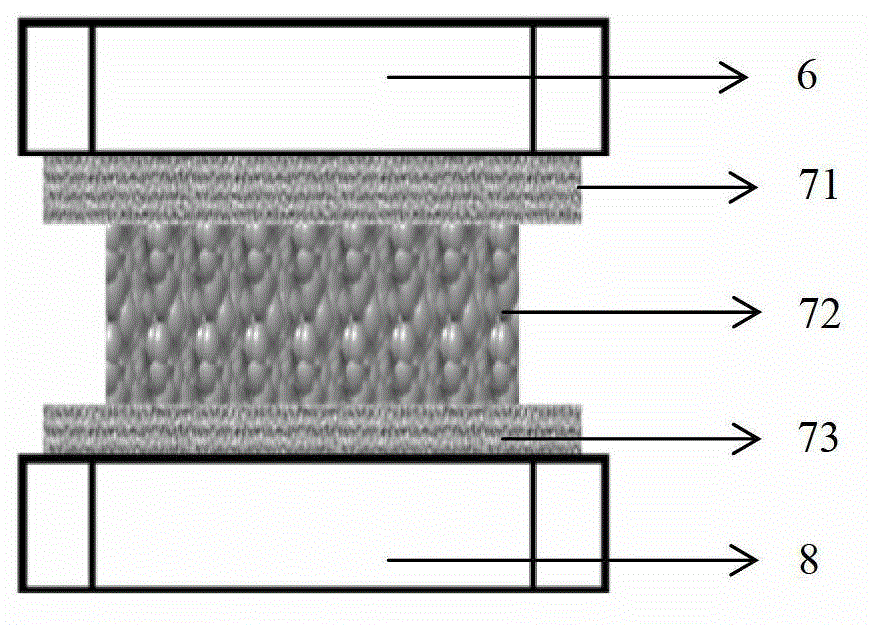

[0061] First, the above-mentioned catalyst and 5% PTFE emulsion are mixed in a certain volume of isopropanol in a certain proportion, and the spray slurry is obtained after hundreds of times of ultrasonication in an ice bath, and then the PTFE film is used as the substrate, and the catalytic layer is prepared by heating and spraying. as attached image 3 , and finally the PTFE film with the anode catalytic layer 142, the Nafion membrane 143, and the PTFE film of the cathode catalytic layer 144 are placed under a pressure of 750 N cm -2 The PTFE film was peeled off by hot pressing at a temperature of 135 °C to obtain the tested membrane electrode. Among them, MEA-1 and MEA-2 are IrO 2 / ATO and IrO 2 / Cs 1.5 Membrane electrode prepared by HWA-ATO two catalysts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com