Preparation method of pressure-sensitive conductive membrane

A technology of conductive film and conductive particles, which is used in cable/conductor manufacturing, conductors, circuits, etc., can solve the problems of single conductive effect, can not meet the anisotropic conduction of special electronic devices, etc., and achieves a simple and fast preparation method and is convenient for large-scale Production, the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

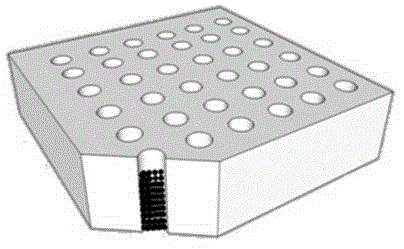

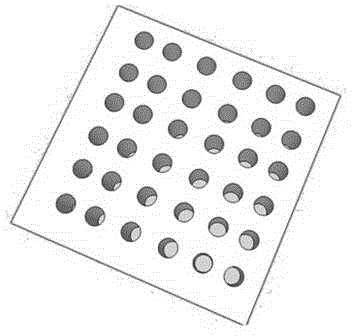

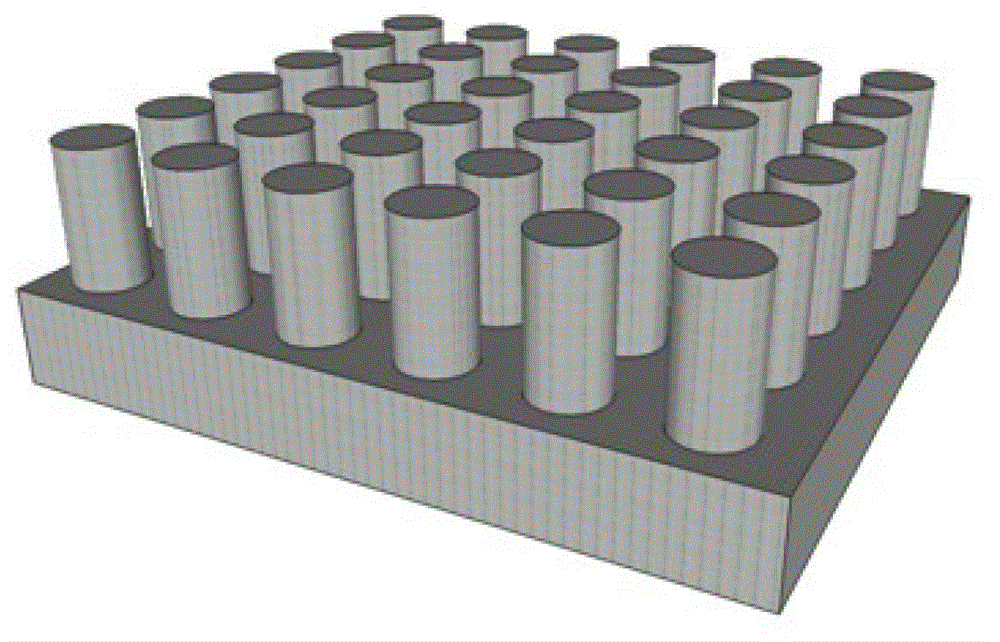

[0029] Select a silicon wafer, and use a conventional etching method to etch a regular array of micron-scale columns with a diameter of 1 μm and a height of 20 μm on the surface of the silicon wafer (such as figure 1 shown); the polydimethylsiloxane (PDMS) prepolymer and the curing agent for curing the polydimethylsiloxane prepolymer (the polydimethylsiloxane prepolymer used and the curing agent for the prepolymer The curing agent of the polymer is SYLGARD184 silicone rubber product of Dow Corning Company in the United States) according to the mass ratio of PDMS prepolymer: curing agent is 10:1, and the mixture obtained after mixing the PDMS prepolymer and curing agent is mixed with toluene according to the mass ratio Mix 1:1 to obtain a mixed solution with a mass concentration of 50%, and drop-coat the obtained mixed solution onto a silicon wafer with a regularly arranged cylindrical array on the surface, and then put the silicon wafer into an oven at a temperature of 120°C. ...

Embodiment 2

[0031] Select a glass sheet, and use a conventional etching method to etch a regular array of micron-sized columns with a diameter of 5 μm and a height of 20 μm on the surface of the glass sheet; dissolve polyethylene glycol (PEG) in ethanol to prepare a mass A polyethylene glycol solution with a content of 5%, and the obtained polyethylene glycol solution is drip-coated on a glass sheet with a regularly arranged cylindrical array on the surface, and then the glass sheet is placed in an oven at a temperature of 80°C for 3 hours. ; The cured polyethylene glycol film is separated from the glass sheet to obtain a pressure-sensitive elastic polyethylene glycol film with a porous structure with a pore size of 5 μm. Conductive gold particles with a particle size of about 10nm (electron micrographs such as Figure 4 Shown) and isopropanol preparation of conductive gold particles with a mass content of 10% of the suspension was filled in the pores of the prepared pressure-sensitive el...

Embodiment 3

[0033]Select a quartz plate, and use a conventional etching method to etch a micron-scale regularly arranged cylindrical array with a diameter of 20 μm and a height of 20 μm on the surface of the quartz plate; dissolve polyvinyl alcohol (PVA) in ethylene glycol to prepare A polyvinyl alcohol solution with a mass content of 50%, the obtained polyvinyl alcohol solution is drip-coated on a quartz plate with a regularly arranged cylindrical array on the surface, and then the quartz plate is placed in an oven with a temperature of 80°C for curing for 1 hour; The cured polyvinyl alcohol film is separated from the quartz plate to obtain a pressure-sensitive elastic polyvinyl alcohol film with a porous structure with a pore diameter of 20 μm. Fill the suspension with a mass content of 50% conductive copper particles prepared from conductive copper particles with a particle size of about 1 μm and ethanol into the pores of the prepared pressure-sensitive elastic polyvinyl alcohol film wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com