Novel beta-cyclodextrin host-guest complex antibacterial starch-base plastic and method for preparing same

A technology of starch-based plastics and cyclodextrin, which is applied in the field of novel β-cyclodextrin host-guest inclusion compound antibacterial starch-based plastics and its preparation, can solve the problem that the antibacterial performance of antibacterial plastic products cannot be fully exerted, the antibacterial effect is reduced, Short antibacterial period and other issues, to achieve the effect of simple coating design, long-lasting antibacterial effect, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

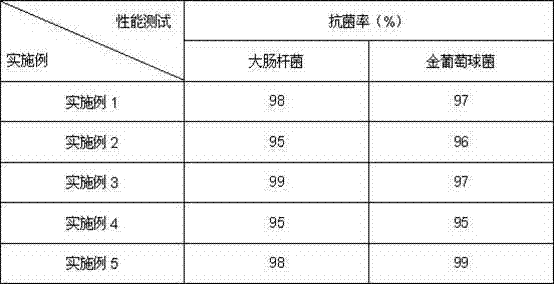

Examples

Embodiment 1

[0017] An antibacterial plastic, comprising the following components in mass percentage: plastic raw material starch filling PP95%, antibacterial masterbatch 4%, dispersant 0.2%, antioxidant 0.8%, the preparation method of the antibacterial starch plastic of the present embodiment comprises the following steps: Among them, the plastic raw material is starch-filled PP, the antibacterial masterbatch is β-cyclodextrin host-guest inclusion compound zinc oxide antibacterial masterbatch, the dispersant is sodium stearate, and the antioxidant is 1010. Wherein the dispersant used may be one of zeolite, silica, bentonite, sepiolite, diatomaceous earth or sodium stearate. One of MD-1024, JX-1076, 702, 164 or 1010 can be used as the antioxidant.

[0018] (1): Prepare thermoplastic starch according to the usual steps for preparing pp filled starch;

[0019] (2): Mix thermoplastic starch 20%, PP75%, dispersant 0.2%, antioxidant 0.8%, and β-cyclodextrin host-guest inclusion complex nano-zi...

Embodiment 2

[0021] The antibacterial masterbatch is β-cyclodextrin host-guest inclusion complex nano-titanium dioxide, and other formulations are the same as in Example 1.

Embodiment 3

[0023] The antibacterial masterbatch is β-cyclodextrin host-guest inclusion complex nano-silver, and other formulations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com