Chloride molten salt heat transfer and heat storage material, as well as preparation method and use thereof

A heat storage material, molten salt technology, applied in heat exchange materials, chemical instruments and methods, bulk chemical production, etc. Improve the value of development and utilization, good thermal stability, and the effect of wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A chloride molten salt heat transfer heat storage material, prepared by the following steps:

[0032] Mix 30wt% sodium chloride and 70wt% calcium chloride and stir evenly, statically heat until the solids are completely melted, then keep warm for 10 to 30 minutes, then naturally cool to room temperature, and mechanically pulverize to obtain chloride molten salt heat transfer storage hot material.

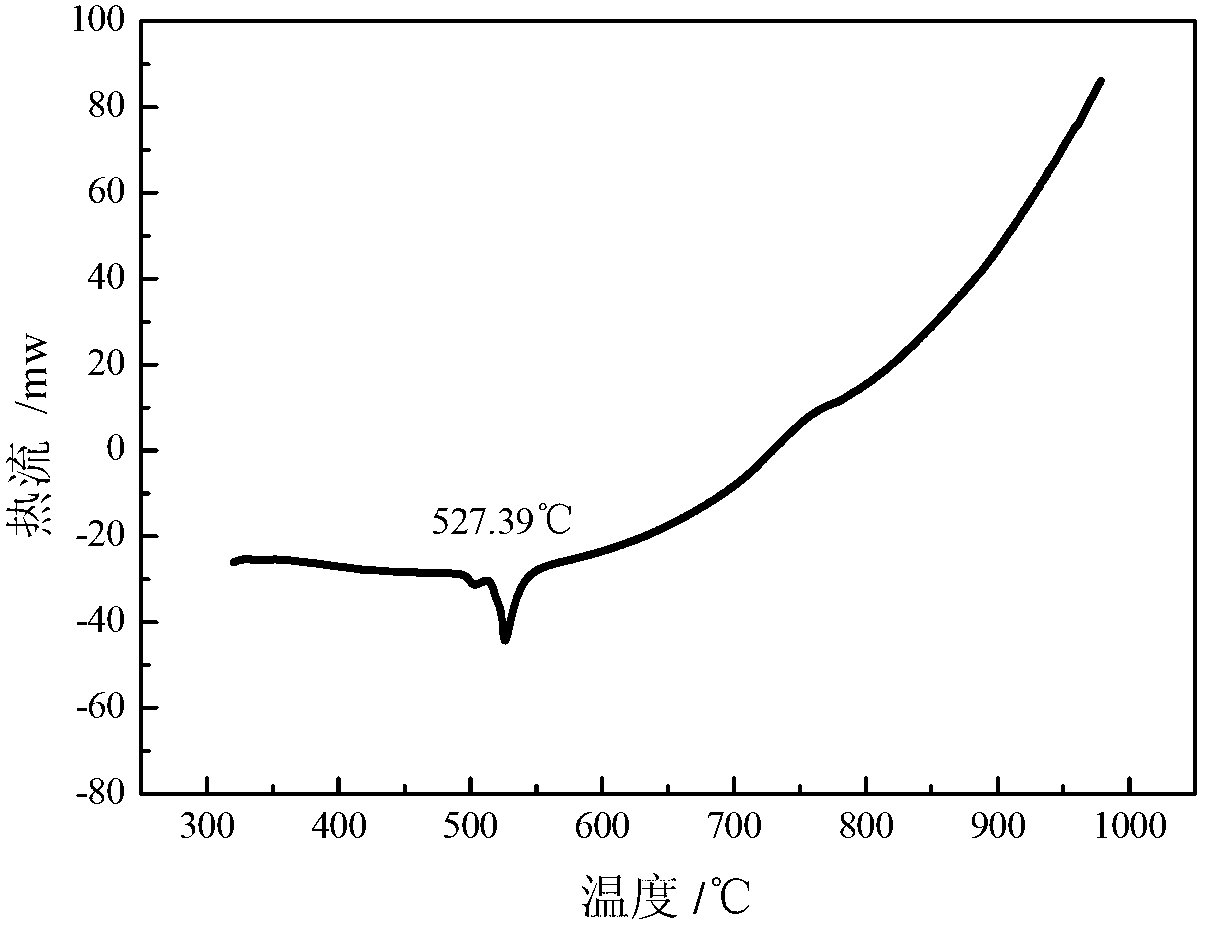

[0033] Using a differential scanner to test the melting point of the chloride molten salt heat transfer and heat storage material prepared in this example, the obtained curve is as follows figure 1 shown. The test results showed that the melting point of the molten salt was 527.39°C.

Embodiment 2

[0035] A chloride molten salt heat transfer heat storage material, prepared by the following steps:

[0036] Mix 31.5wt% sodium chloride and 68.5wt% calcium chloride and stir evenly, statically heat until the solids are completely melted, then keep warm for 10 to 30 minutes, then naturally cool to room temperature, and mechanically pulverize to obtain chloride molten salt heat storage material.

[0037] A differential scanner was used to test the melting point of the chloride molten salt heat transfer and heat storage material prepared in this example. The melting point of the molten salt was measured to be 510.25° C., which was lower than that of Example 1.

Embodiment 3

[0039] A chloride molten salt heat transfer heat storage material, prepared by the following steps:

[0040] Mix 32.7wt% sodium chloride and 67.3wt% calcium chloride and stir evenly, statically heat until the solids are completely melted, then keep warm for 10 to 30 minutes, then naturally cool to room temperature, and mechanically pulverize to obtain chloride molten salt. heat storage material.

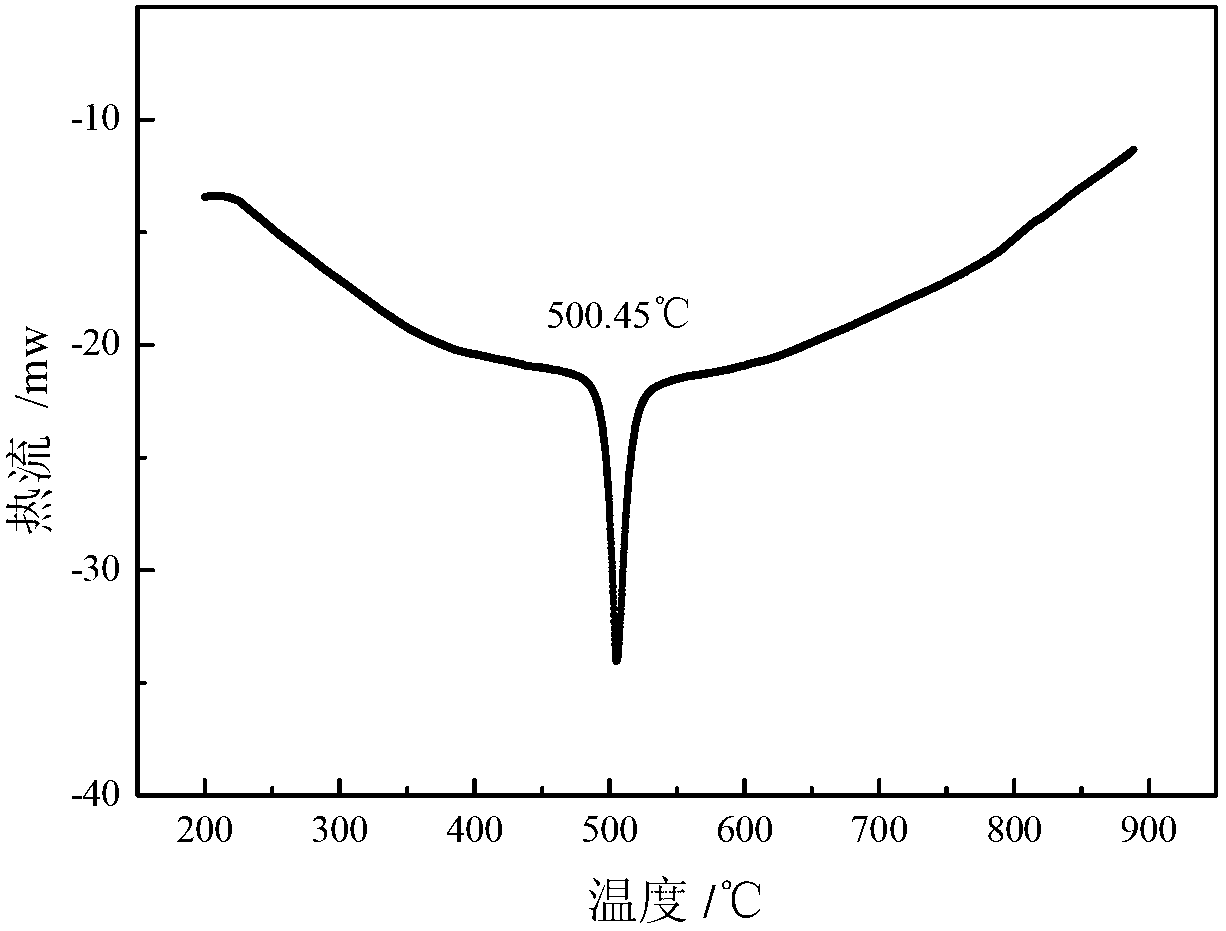

[0041] Using a differential scanner to test the melting point of the chloride molten salt heat transfer and heat storage material prepared in this example, the obtained curve is as follows figure 2 shown. The test results showed that the melting point of the molten salt was 500.45°C. All lower than Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com