Diamond grinding wheel and processing technic thereof

A technology of diamond grinding wheel and processing technology, which is applied in the field of diamond grinding wheel for grinding automobile brake discs and its processing technology, which can solve the problems of affecting the service life of equipment, shortening the service life of grinding wheel, and heavy weight of silicon carbide grinding wheel, so as to save manpower and material resources, Effects of improving quality and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention are given below to further describe the composition of the present invention in detail.

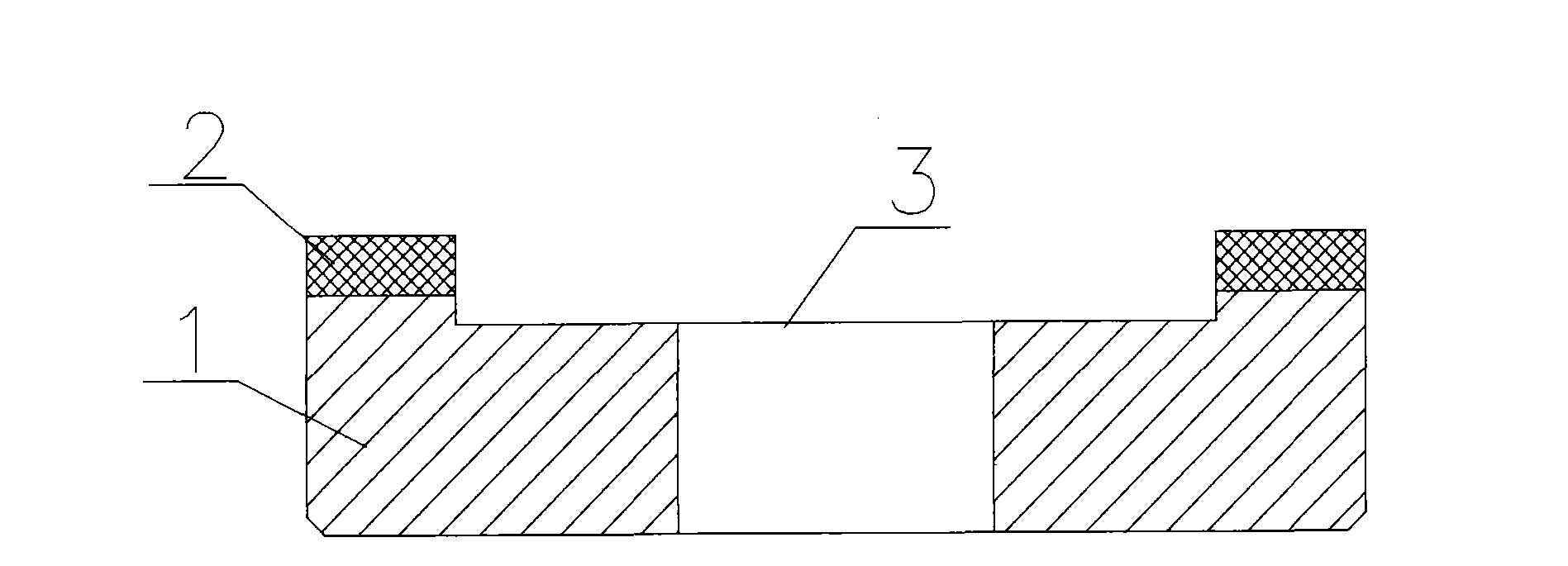

[0021] The diamond grinding wheel of this embodiment comprises a substrate 1 and a diamond layer 2, the substrate 1 is processed with an inner hole 3, and the substrate 1 is made of aluminum;

[0022] The processing technology of diamond grinding wheel comprises the following steps:

[0023] (1) Ingredients

[0024] The following ingredients are proportioned according to volume percentage: phenolic resin powder 30%, diamond 15%, cubic boron nitride 3.5%, copper powder 5%, chromium oxide 20%, zinc oxide 5%, hemihydrate gypsum powder 5%, oxide Magnesium 3%, molybdenum disulfide 5%, sodium fluorosilicate 5%, the porosity formed is 3.5%;

[0025] (2) hot pressing

[0026] Put the above ingredients into the ball mill to mix and pulverize, then weigh them. After the grinding wheel mold is coated with release agent, then put the weighed ing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com