Carbon fiber electromagnetic wave absorbing material and preparation method thereof

A technology of electromagnetic wave absorption and carbon fiber, which is applied in the direction of chemical instruments and methods, other chemical processes, lamination devices, etc., can solve the problems of long development cycle and limited wave absorption bandwidth, and achieve low preparation cost, wide operating frequency band, and preparation The effect of simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

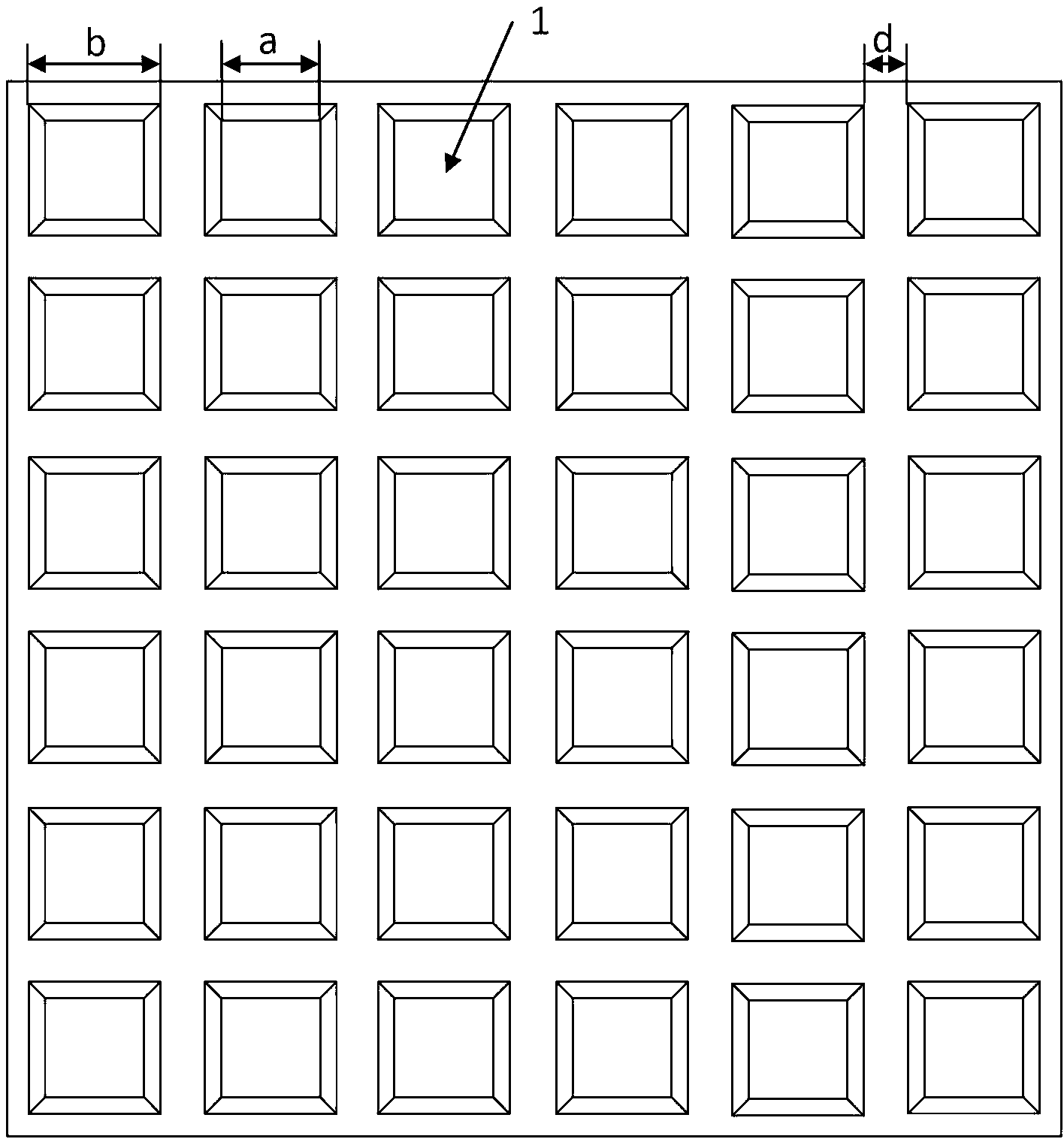

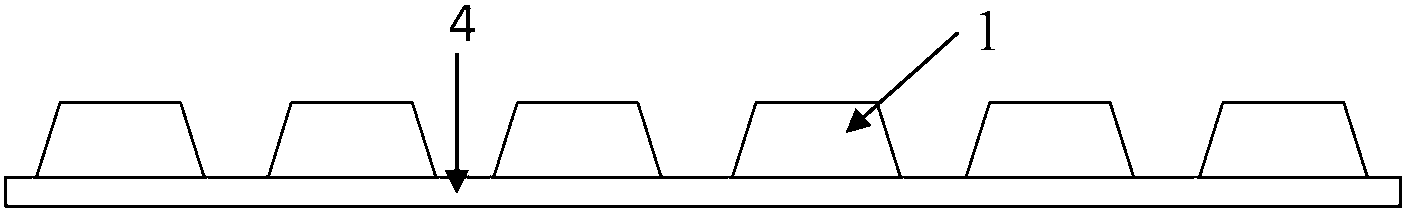

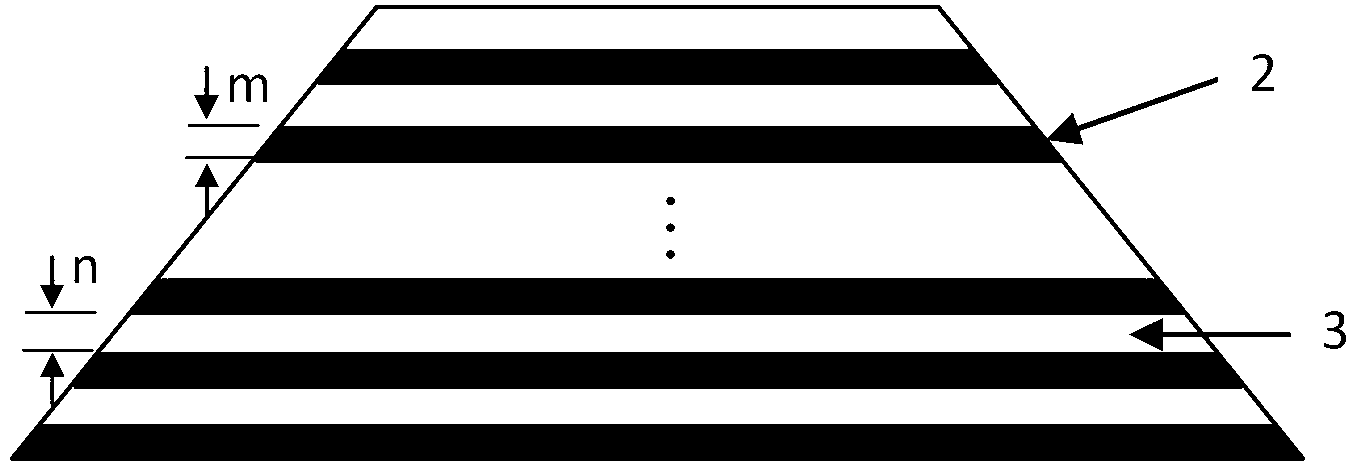

[0027] a kind of like Figure 1 to Figure 5 The shown carbon fiber electromagnetic wave-absorbing material of the present invention is mainly composed of square prisms 1 periodically distributed on the conductive substrate 4 (metal aluminum substrate is used in this embodiment), and the regular prism is composed of Carbon fiber layers 2 and dielectric layers 3 are alternately stacked in a direction perpendicular to the plane of the conductive substrate 4 . In this embodiment, the periodic distribution of the regular square prisms 1 means that the regular square prisms 1 are arranged in a matrix. The side length b of the lower bottom of the regular square prism 1 is 8.4mm, the side length a of the upper bottom of the regular square truss is 4.5mm, and the distance d between two adjacent regular square trusses is 2.0mm. The carbon fiber layer 2 in this embodiment is made of carbon fiber-reinforced epoxy resin-based composite material, especially a resin composite material reinf...

Embodiment 2

[0033] a kind of like Figure 1 ~ Figure 3 The carbon fiber electromagnetic wave-absorbing material of the present invention shown, the carbon fiber electromagnetic wave-absorbing material is mainly composed of regular square prisms 1 periodically distributed on the conductive substrate 4, and the regular square prisms are composed of carbon fiber layers 2 and medium layers 3 in the vertical direction. They are alternately stacked in the direction of the plane of the conductive substrate 4 . In this embodiment, the periodic distribution of the regular square prisms 1 means that the regular square prisms 1 are arranged in a matrix. The side length b of the lower bottom of the regular square truss 1 is 7.0mm, the side length a of the upper bottom of the regular square truss is 3.8mm, and the distance d between two adjacent regular square trusses is 1.5mm. The carbon fiber layer 2 in this embodiment is made of carbon fiber reinforced epoxy resin matrix composite material, and th...

Embodiment 3

[0037] a kind of like Figure 1 ~ Figure 3 The carbon fiber electromagnetic wave-absorbing material of the present invention shown, the carbon fiber electromagnetic wave-absorbing material is mainly composed of regular square prisms 1 periodically distributed on the conductive substrate 4, and the regular square prisms are composed of carbon fiber layers 2 and medium layers 3 in the vertical direction. Alternately stacked in the direction of the plane of the conductive substrate 4 . In this embodiment, the periodic distribution of the regular square prisms 1 means that the regular square prisms 1 are arranged in a matrix. The side length b of the lower bottom of the regular square prism 1 is 10.0mm, the side length a of the upper bottom of the regular square truss is 4.8mm, and the distance d between two adjacent regular square trusses is 2.0mm. The carbon fiber layer 2 in this embodiment is made of carbon fiber reinforced epoxy resin matrix composite material, and the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com