Method for preparing one-dimensional magnetic fluorescent nanochain

A nano-chain, high-magnetic technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem that dipole interactions are difficult to maintain the orderly structure of superparamagnetic nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

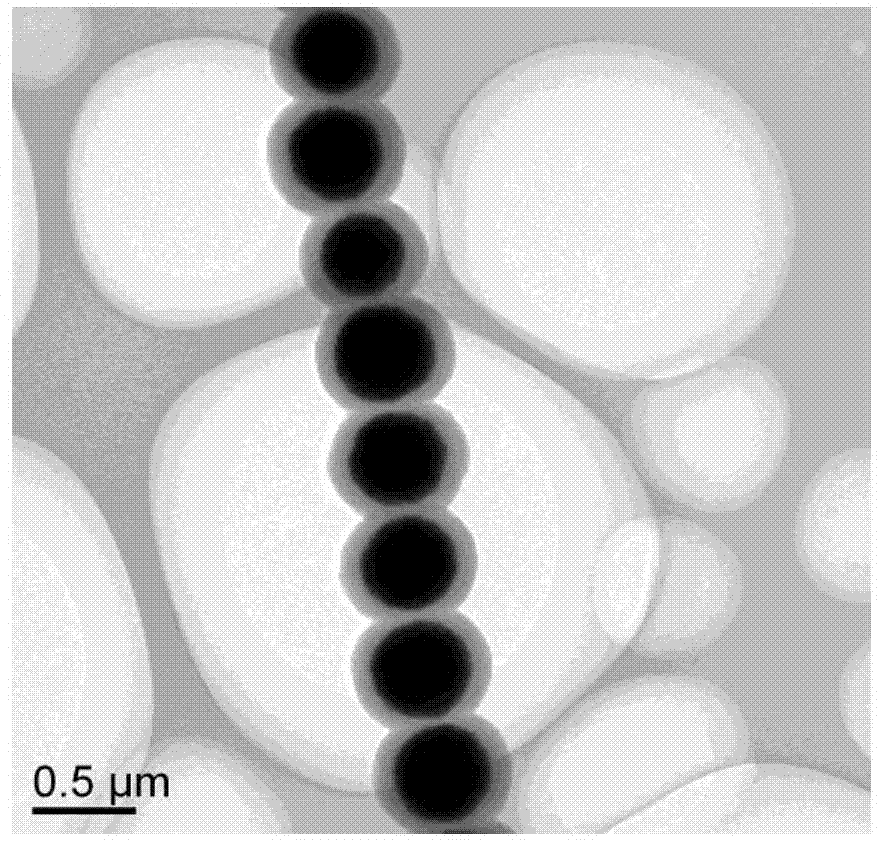

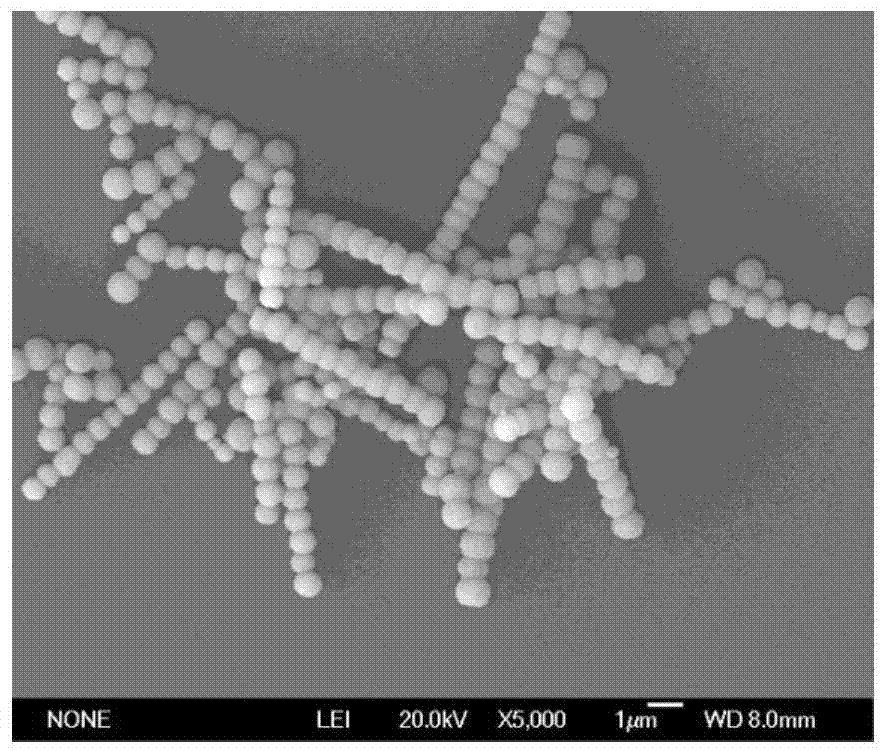

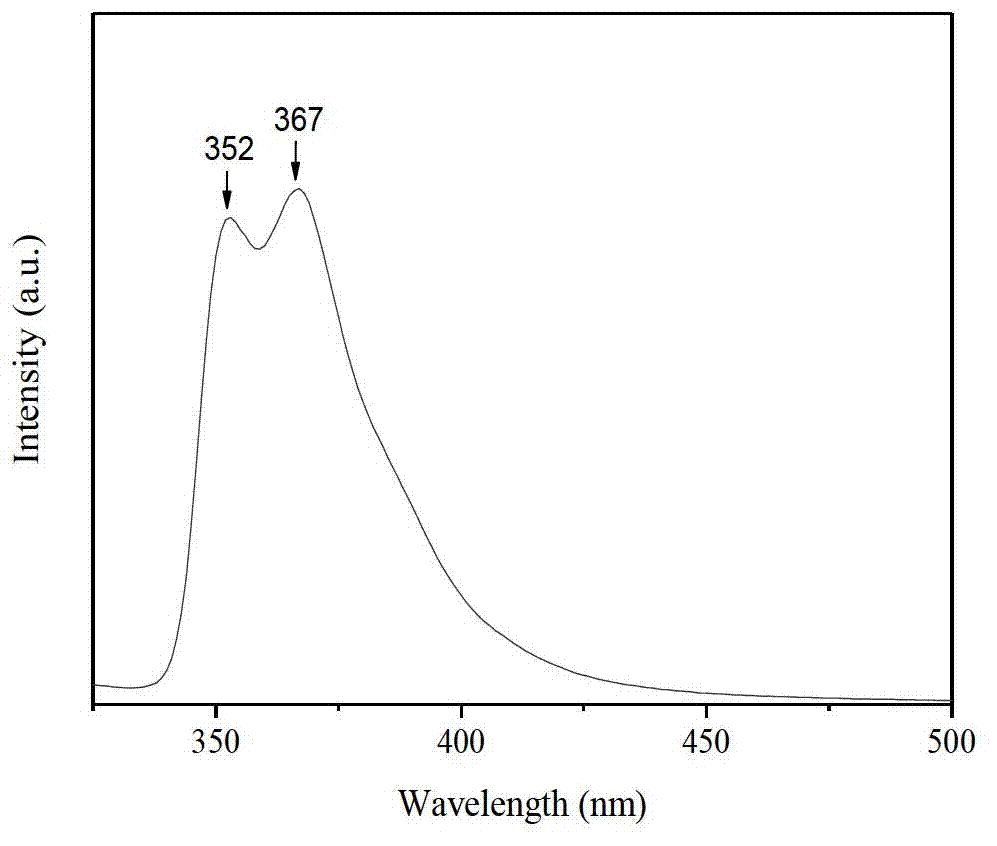

[0025] In a 100mL reactor equipped with a condenser, add 70g of acetonitrile and 5g of ethanol; 0.04g of Fe 3 o 4 The microspheres were added to a 100mL reactor; a magnet with a magnetic field strength of 120Gs was added to the reactor; 0.06g GMA (glycidyl methacrylate), 0.06g DVB (divinylbenzene) and 0.03gNVCz ( Vinyl carbazole) and 0.007g of BPO (dibenzoyl peroxide), shake to dissolve, add to the reactor, mix well; gradually raise the temperature to 82 ° C, polymerize for 4 hours; magnetically separate the obtained product, pour Remove the supernatant, add anhydrous ethanol, ultrasonically disperse, and then perform magnetic separation; repeat this process several times to remove excess monomers and polymers. Vacuum drying at room temperature yields dark brown one-dimensional magnetic fluorescent nanochains.

[0026] The resulting one-dimensional magnetic fluorescent nanochains have a chain length of about 2 μm, a magnetic responsivity of 64 emu / g, and a magnetic content o...

Embodiment 2

[0028] In a 100mL reactor equipped with a condenser, add 78g of acetonitrile; 0.06g of Fe 3 o 4 The microspheres were added to a 100mL reactor; a magnet with a magnetic field strength of 400Gs was added to the reactor; 0.15g GMA (glycidyl methacrylate), 0.22g EGDMA (ethylene glycol dimethacrylate) were added to the beaker and 0.08g of NVCz (vinyl carbazole) and 0.018g of AIBN (azobisisobutyronitrile), after shaking and dissolving, add to the reactor and mix well; gradually heat up to 80°C, and polymerize for 1.5h; the obtained The product is subjected to magnetic separation, the supernatant liquid is poured off, anhydrous ethanol is added to disperse by ultrasonic, and then magnetic separation is carried out; repeated washing in this way is repeated several times to remove excess monomer and polymer. Vacuum drying at room temperature yields dark brown one-dimensional magnetic fluorescent nanochains.

[0029] The resulting one-dimensional magnetic fluorescent nanochains have ...

Embodiment 3

[0031] In a 100mL reactor equipped with a condenser, add 70g of acetonitrile, 5g of methanol and 5g of acetone; add 0.07g of Fe3O4 microspheres into the 100mL reactor; add a magnet with a magnetic field strength of 800Gs to the reactor; add 0.22g GMA (glycidyl methacrylate), 0.26g DVB (divinylbenzene), 0.12g NVCz (vinyl carbazole) and 0.015g BPO (dibenzoyl peroxide), after shaking and dissolving, add Put it into the reactor, mix well; gradually raise the temperature to 84°C, and polymerize for 3 hours; conduct magnetic separation on the obtained product, pour off the supernatant liquid, add absolute ethanol to disperse by ultrasonic, and then perform magnetic separation; repeat this way for several times, to remove excess monomer and polymer. Vacuum drying at room temperature yields dark brown one-dimensional magnetic fluorescent nanochains.

[0032] The resulting one-dimensional magnetic fluorescent nanochains have a chain length of about 5 μm, a magnetic responsivity of 40 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic responsiveness | aaaaa | aaaaa |

| Magnetic responsiveness | aaaaa | aaaaa |

| Magnetic responsiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com