Inorganic zinc-rich anticorrosive nano-attapulgite coating and its preparation method

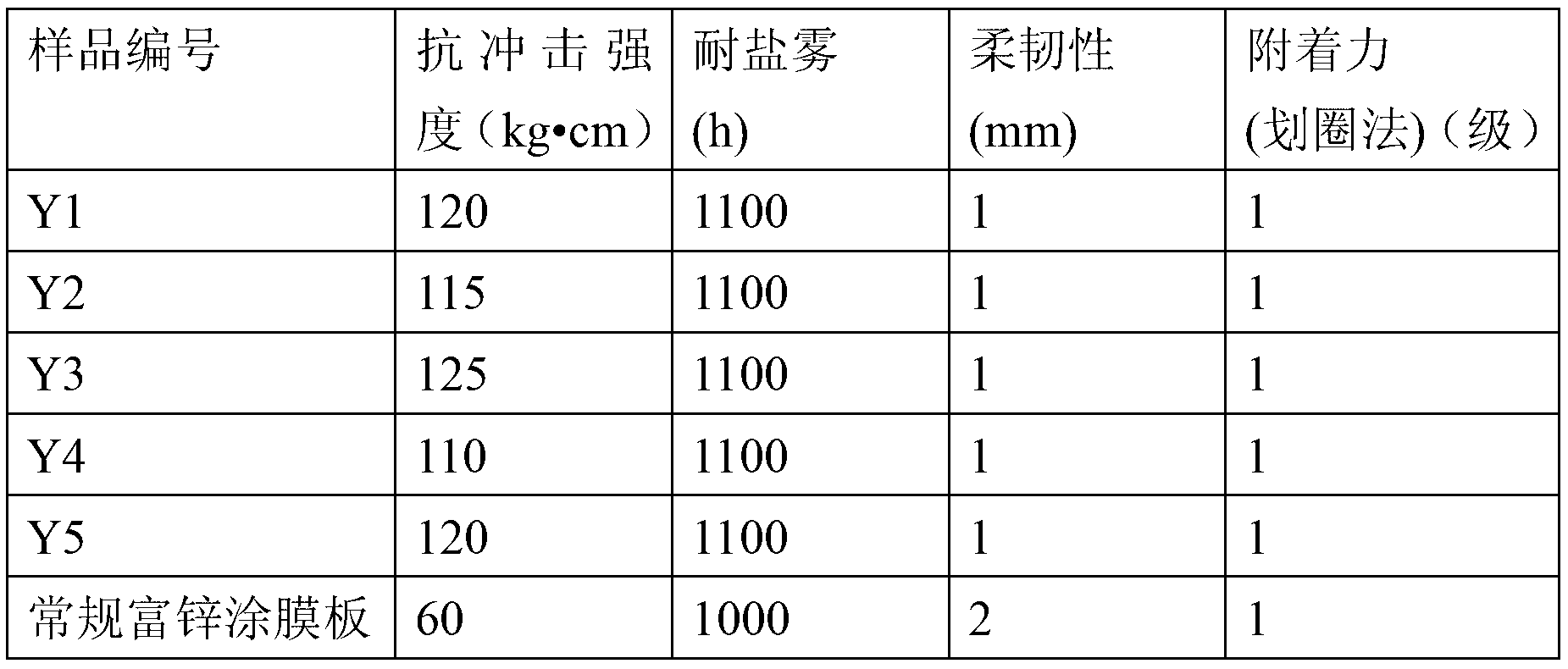

A technology of inorganic zinc-rich anti-corrosion coatings, applied in anti-corrosion coatings, alkali metal silicate coatings, etc., can solve the problems of poor mechanical properties of water-based zinc-rich anti-corrosion coatings, low bonding force between coatings and substrates, low impact strength and Poor flexibility and other problems, to achieve the effects of crack suppression, strong bonding, and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of nano attapulgite inorganic zinc-rich anticorrosion coating, comprising the following steps:

[0036] 1) Preparation of component A:

[0037] Based on 100% of the mass percentage of component A, component A adopts the following components in mass percentage;

[0038] Inorganic binder 68%~87%;

[0039]Synthetic resin emulsion 8% to 30%;

[0040] Wetting and dispersing agent 1.5%~4%;

[0041] Defoamer 0.5% ~ 2%;

[0042] Put the inorganic binder with a modulus of 3.0 to 5.0 (one or more of potassium silicate solution, sodium silicate solution, lithium silicate solution) into the container, and add the above synthetic resin emulsion (benzene Acrylic emulsion or silicone acrylic emulsion), wetting and dispersing agent (polycarboxylate sodium salt type wetting and dispersing agent) and defoamer (polyether type defoamer or silicon dioxide type defoamer) to prepare component A;

[0043] 2) Preparation of nano-attapulgite in component B: Add 50g of a...

Embodiment 1

[0051] 1) Take 87 grams of potassium silicate-sodium silicate solution with a modulus of 3.5 (produced by Hebei Xingtai Dayang Chemical Co., Ltd., model DY-KN), and add 10 grams of styrene-acrylic emulsion (Rohm and Haas AS-398), 2 grams of wetting and dispersing agent (polycarboxylate sodium salt type wetting and dispersing agent SN-5040 produced by Nopco) and 1 gram of defoamer (SPG-10 produced by Nantong Hongfeng Industrial Auxiliary Co., Ltd. Type polyether defoamer), stir to make it completely dispersed, and make component A;

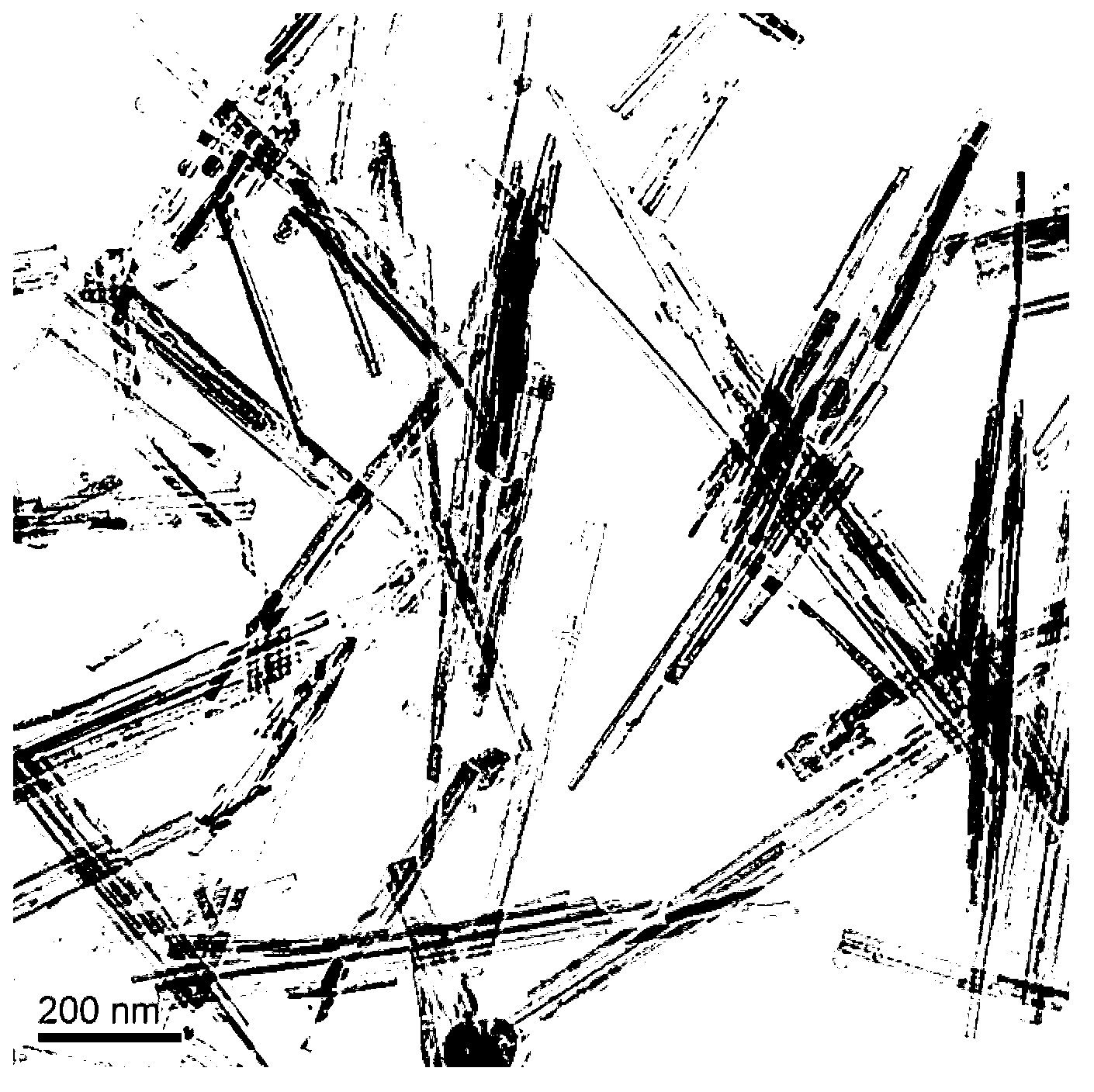

[0052] 2) Add 8 grams of nano-attapulgite (fibrous attapulgite with a diameter of 25-80nm and a length of 0.5-3μm) into the above-mentioned component A solution, and stir for 1.5 hours at 1500 rpm to make the nano-attapulgite in the liquid Disperse evenly in the medium, and finally add 292 grams of 500-mesh zinc powder, the mass ratio of component A and component B is 1:3, and keep stirring for 30 minutes, and filter to obtain nano attapulgite inor...

Embodiment 2

[0055] 1) Take 81 grams of potassium silicate solution with a modulus of 4.0 (produced by Hebei Xingtai Dayang Chemical Co., Ltd., model DY-K), add 15 grams of styrene-acrylic emulsion (Rohm and Haas AS-398), 2.5 grams of wetting and dispersing agent (the polycarboxylate sodium salt type wetting and dispersing agent SN-5040 produced by Nopco) and 1.5 grams of defoamer (SPG-10 polyether defoamer produced by Nantong Hongfeng Industrial Auxiliary Co., Ltd.) Foaming agent), stir to make it completely dispersed, and make A component.

[0056] 2) Add 10 grams of nano-attapulgite (fibrous attapulgite with a diameter of 25-80 nm and a length of 0.5-3 μm) into the above-mentioned component A solution, and stir for 1.5 hours at 1500 rpm to make the nano-attapulgite in the liquid Disperse evenly in the medium, and finally add 290 grams of 600-mesh zinc powder, the mass ratio of component A and component B is 1:3, and continue stirring for 30 minutes, and filter to obtain nano-attapulgite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap