Method for preparing corylus avellana-corylus heterophylla fisch hybrid hazelnut oil by aqueous enzymatic method

A technology of Pingou hazelnut oil and water enzymatic method, applied in the direction of edible oil/fat, fat oil/fat production, fat production, etc., to achieve the effect of maintaining nutrients, simple process, and maintaining color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Drying of raw materials: put the harvested hazelnuts in a warehouse with the following conditions for 2-3 months: low temperature (5-20°C), dry (relative humidity 60%-70%), avoid light and ventilation, and keep the fruit moisture It can be controlled to reach the 5%-7% standard, and it will not deteriorate after continuous storage for 2 years.

[0022] 2. Cleaning and shelling: clean and remove impurities, use TFXZ-500 hazelnut shelling machine (marketed) to process raw materials, and the shelling rate is above 95%.

[0023] 3. Crushing: Put the shelled hazelnut kernels into ST-06 300g multifunctional grinder (marketed) to grind, and grind for 30 seconds to obtain the hazelnut powder required for enzymatic hydrolysis.

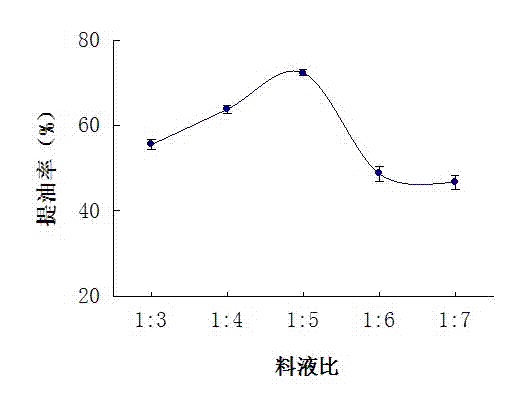

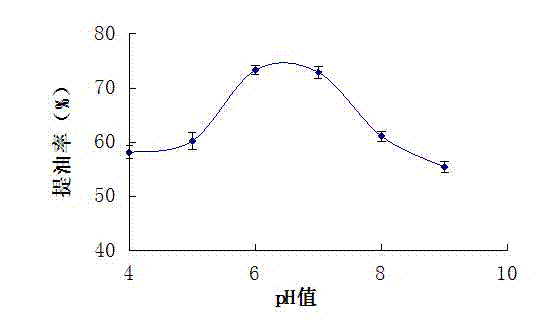

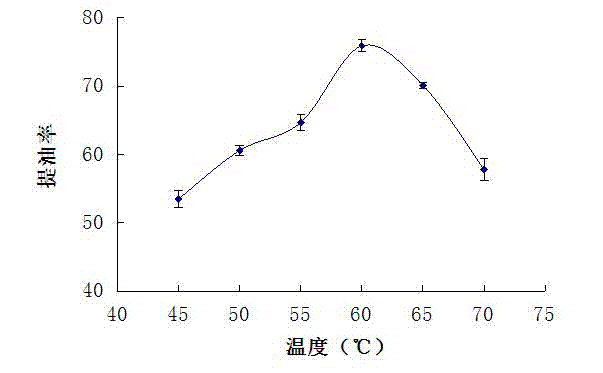

[0024] 4. Enzymatic hydrolysis: The ratio of material to liquid (mass ratio of hazelnut powder to deionized water) is 1:5, pH value is 6.3, and α-amylase and papain are used for compound enzymolysis, and the addition amount is calculated according to ...

Embodiment 2

[0029] 1. Drying of raw materials: Drying of raw materials: put the harvested hazelnuts in a warehouse with the following conditions for 2-3 months: low temperature (5-20°C), dry (relative humidity 60%-70%) and avoid light and ventilation , the moisture content of the fruit can be controlled to reach the standard of 5%-7%, and it can be stored continuously for 2 years without deterioration.

[0030] 2. Cleaning and shelling: clean and remove impurities, use TFXZ-500 hazelnut shelling machine to process raw materials, and the shelling rate is above 95%.

[0031] 3. Crushing: Put the shelled hazelnut kernels into ST-06 300g multifunctional pulverizer for crushing, and crush for 30 seconds to obtain the hazelnut powder required for enzymatic hydrolysis.

[0032] 4. Enzymolysis: The ratio of solid to liquid is 1:6, the pH value is 5, and the combined enzymolysis with α-amylase and papain is used. The addition amount is calculated according to the mass percentage of hazelnut powder...

Embodiment 3

[0037] 1. Drying of raw materials: Drying of raw materials: put the harvested hazelnuts in a warehouse with the following conditions for 2-3 months: low temperature (5-20°C), dry (relative humidity 60%-70%) and avoid light and ventilation , the moisture content of the fruit can be controlled to reach the standard of 5%-7%, and it can be stored continuously for 2 years without deterioration.

[0038] 2. Cleaning and shelling: clean and remove impurities, use TFXZ-500 hazelnut shelling machine to process raw materials, and the shelling rate is above 95%.

[0039] 3. Crushing: Put the shelled hazelnut kernels into ST-06 300g multifunctional pulverizer for crushing, and crush for 30 seconds to obtain the hazelnut powder required for enzymatic hydrolysis.

[0040] 4. Enzymolysis: The ratio of solid to liquid is 1:4, the pH value is 7, and the combined enzymolysis with α-amylase and papain is used. The addition amount is calculated according to the mass percentage of hazelnut powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com