pot heat exchanger

A technology for heat exchangers and gas purification, applied in heat exchange equipment, heat exchangers, indirect heat exchangers, etc., to achieve low total system energy loss, uniform or balanced raw gas velocity, and reduce fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

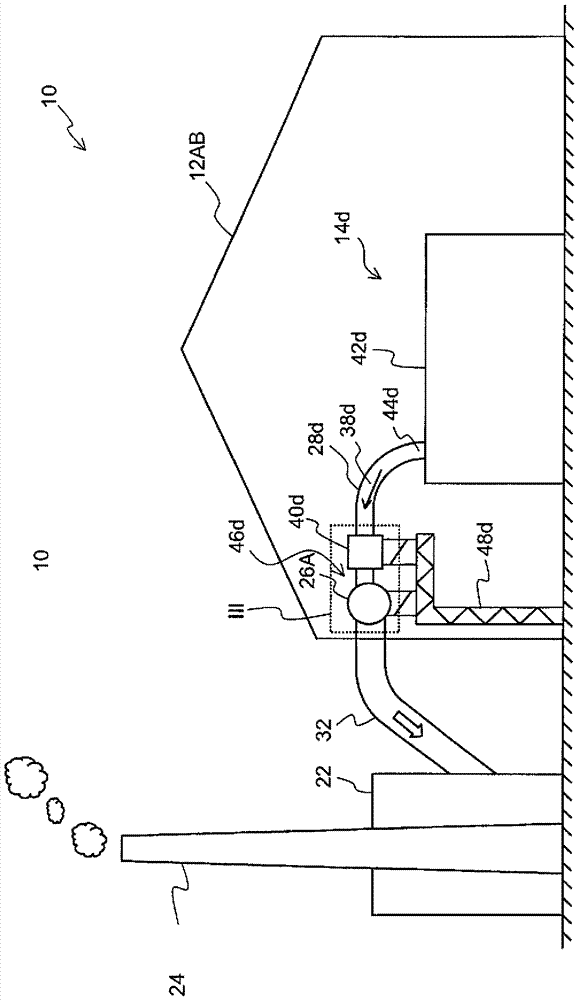

[0026] figure 1 is a schematic diagram of the aluminum manufacturing plant 10 viewed from above. Aluminum fabrication plant 10 includes a plurality of pot rooms or potrooms 12AB, 12CD, each pot room including a plurality of aluminum preparation melting pots or pots 14 . The electrolysis cells 14 are arranged in a series of electrolysis cells in a manner well known to those skilled in the art. The series of electrolysers comprises a plurality of electrolysers connected in series in a direct current (DC) loop. figure 1 A first electrolysis cell bay 12AB and a second electrolysis cell bay 12CD are shown, each housing a respective series of electrolysis cells 16AB, 16CD. although figure 1 The single series of pots 16AB, 16CD in are shown housed in a single pot room 12AB, 12CD, but a single series of pots defined as a plurality of melting pots electrically connected in series could also simply extend across several pot rooms 12 . For example, as an alternative to the configura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com