Spontaneous heating coating for substrate surface and preparation method of spontaneous heating coating

A substrate surface, self-heating technology, applied in the field of coatings, can solve the problems of limited anti-icing time, heavy workload, delayed flights, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

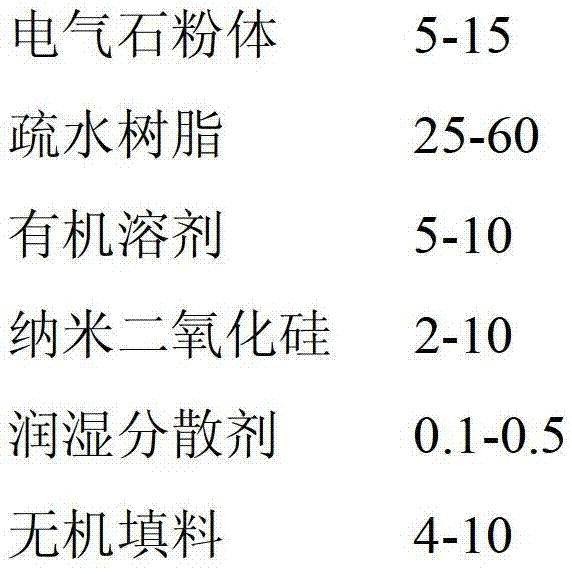

[0065] ① Grind the tourmaline so that it reaches the micron level, and screen it with a 200-mesh filter sieve; mix 9g of tourmaline, 30g of resin, and 7g of organic solvent, disperse in the grinder at a high speed of 4000r / min for 30min, and discharge the material to obtain tourmaline heating paint;

[0066] ②Mix 5g of nano-silica, 30g of organic solvent and 0.1g of wetting and dispersing agent and disperse in an ultrasonic disperser for 15 minutes; add 1.5g each of iron red, titanium dioxide, calcium carbonate, talcum powder and kaolin, Disperse and grind in the grinder for 30min at a speed of 1000r / min for 30min; add 30g of hydrophobic resin, then disperse and grind for 30min at 1000r / min, and discharge to obtain a superhydrophobic coating;

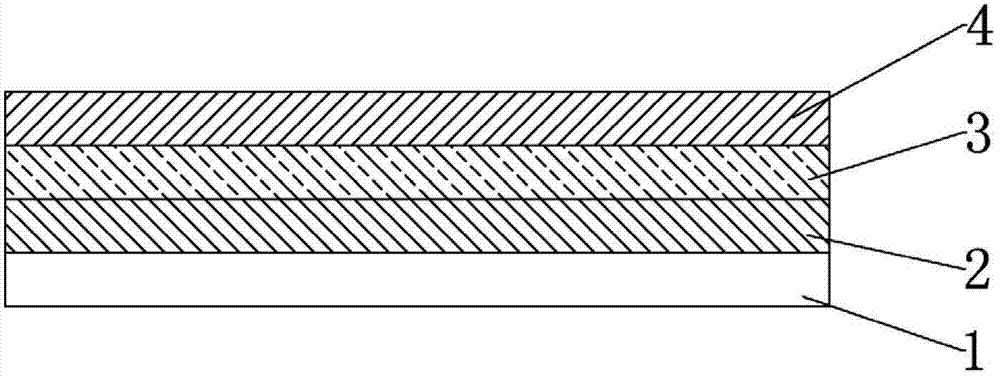

[0067] ③ Coating: first coat the base material with YA-631 organic insulating paint to obtain the insulating bottom layer 1, place the carbon fiber excitation layer 2 on it, and then apply the self-heating layer coating on the carbon fi...

Embodiment 2

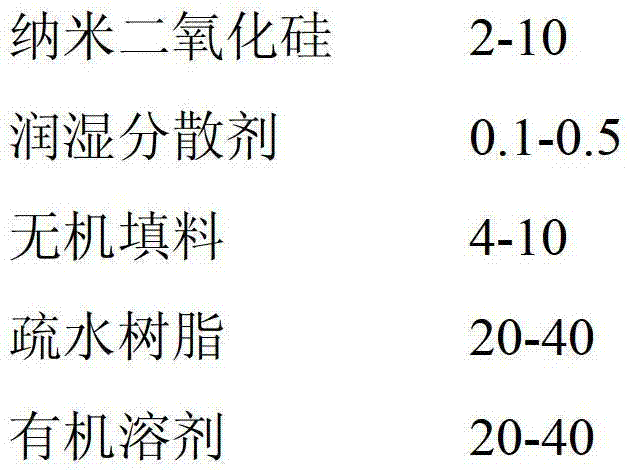

[0071] ①Mix 5g of nano-silica, 30g of organic solvent and 0.1g of wetting and dispersing agent and disperse in an ultrasonic disperser for 15 minutes; add 2.5g each of iron red, titanium dioxide, talcum powder, and 9g of tourmaline powder, grinder Disperse in the grinding machine at a speed of 4000r / min for 30min; add 50g of resin and 10g of solvent, then disperse and grind at 1000r / min for 30min, and discharge to obtain a superhydrophobic and self-heating integrated coating.

[0072] ② First, apply YA-631 organic silicon insulating coating on the base material to make an insulating bottom layer, place the carbon fiber excitation layer on it, and after drying, apply a super-hydrophobic and self-heating integrated coating, place it at room temperature, and dry.

[0073] In the above steps, the organic solvent is a mixed solution composed of butyl acetate, n-butanol and xylene in a mass ratio of 1:2:3.

[0074] This implementation case can be used for anti-icing and de-icing of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com