Method for preparing cubic phase li4mn5o12

A cubic phase, 24-hour technology, applied in the direction of manganese oxide/manganese hydroxide, manganate/permanganate, etc., can solve the problems of long preparation cycle and complicated operation process, and achieve stable properties and cheap and easy-to-obtain raw materials , the effect of less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

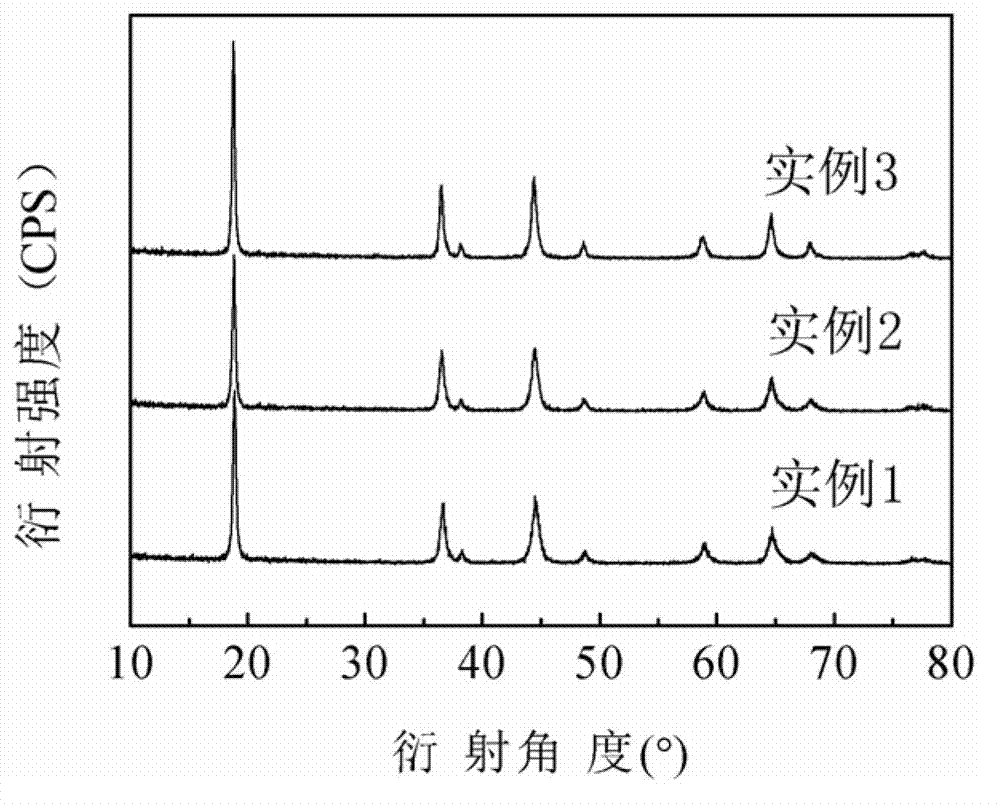

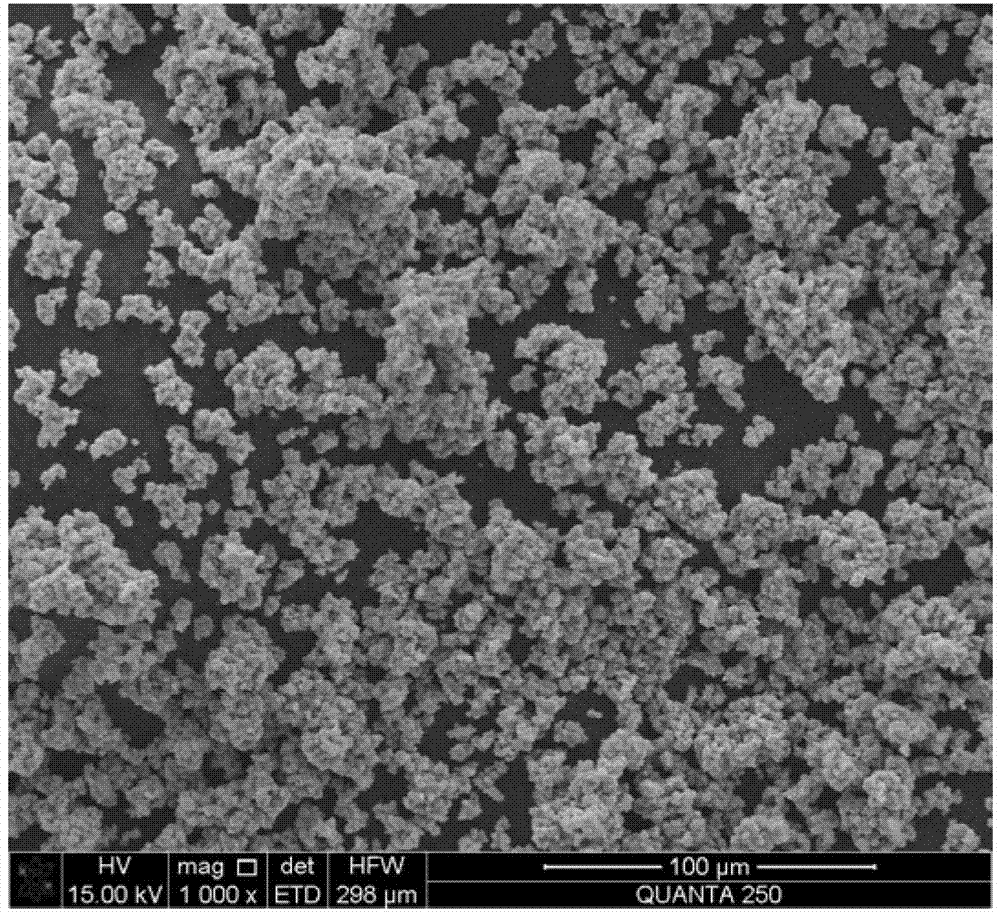

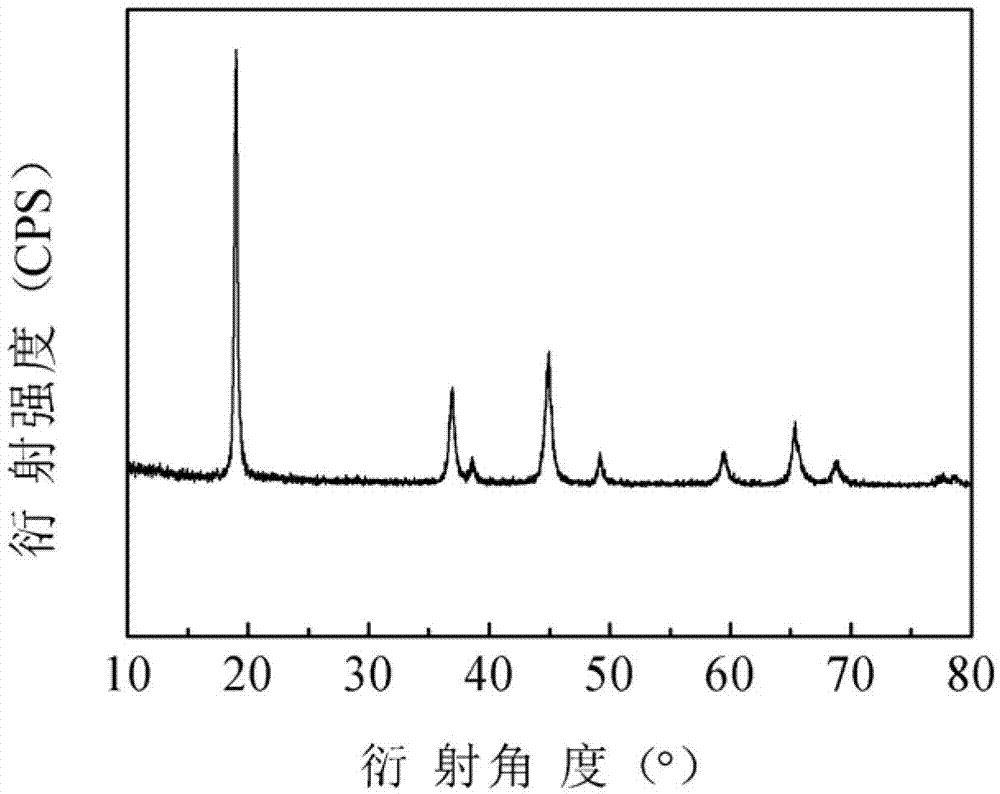

[0031] Grind 14.9g manganese sulfate monohydrate and 3.7g lithium hydroxide monohydrate evenly in a mortar; transfer the obtained mixture to a muffle furnace, and calcinate at 350°C for 24 hours, wherein the air flow rate is 50mL / min, Get the cubic phase Li 4 mn 5 o 12 , the XRD pattern of the product is shown in figure 1 , SEM image see figure 2 ;Depend on figure 1 , 2 It can be seen that the pure phase of Li can be obtained under the calcination conditions adopted 4 mn 5 o 12 , and the particle size of the product is relatively uniform.

Embodiment 2

[0033] Grind 4.6g of manganese carbonate and 1.7g of lithium carbonate in a mortar and mortar; transfer the resulting mixture to a muffle furnace and calcinate at 400°C for 24 hours with an air flow rate of 50mL / min to obtain Li 4 mn 5 o 12 , the XRD pattern of the product is shown in figure 1 .

Embodiment 3

[0035] Grind 4.6g of manganese chloride and 1.7g of lithium chloride in a mortar and mortar; transfer the resulting mixture to a muffle furnace and calcinate at 450°C for 24 hours with an air flow rate of 100mL / min to obtain Li 4 mn 5 o 12 , the XRD pattern of the product is shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com