Fermentation process of culturing excrement

A fermentation process and excrement technology, applied in the field of fermentation process, can solve the problems that it is difficult to meet the needs of farmers in large-scale treatment of cultured excrement, it is difficult for farmers to form a scale, and the process steps are cumbersome, so as to shorten the fermentation time, shorten the fermentation cycle, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

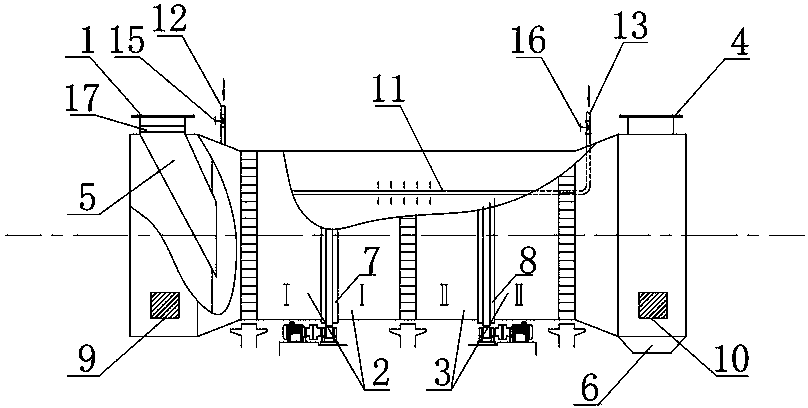

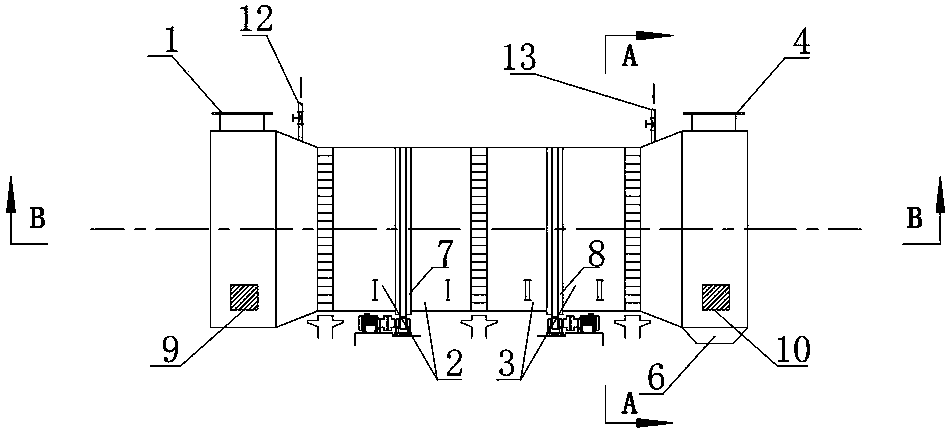

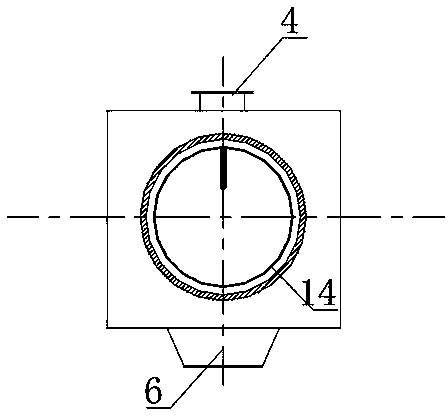

[0036] A kind of fermenting process of culture excrement of the present invention, this fermenting process uses such as Figure 1 to Figure 5 The shown fermenting device for cultured excrement includes a feed port 1 (which doubles as an air inlet), a discharge port 6, an air introduction port 4 and a fermentation device body. From figure 1 It can be seen that the body of the fermentation device is cylindrical, and the exterior is a horizontal cylindrical container as a whole. There are hatches at both ends of the body of the fermentation device to facilitate inspection and maintenance. The feed port 1 is a circular interface, which is located on the upper left side of the fermentation device, and the lower part of the feed port 1 leads to the inner cavity of the fermentation device body through an inclined feed pipe 5 . The discharge port 6 is a circular interface, located on the lower right side of the fermentation device, and the discharge port 6 is provided with a block pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com