Dyhydroxyl cage-type silsesquioxane monomer and preparation method thereof

A technology of silsesquioxane and polysilsesquioxane, applied in the direction of silicon organic compounds, etc., can solve the problems of complex process, gap between mechanical properties and thermal properties, complicated operation, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add DDSQ (5.0g, 0.004mol) and eugenol (1.31g, 0.008mol) into a nitrogen-protected container, add toluene (20mL) as a solvent in the system, raise the temperature to 65°C, and dropwise add Pt with a mass fraction of 0.3 0.2ml of Castel’s Reagent, react at 65°C for 6 hours, then cool down to room temperature, add the reaction mixture to a vacuum distillation device, and distill under reduced pressure at 80°C to remove unreacted eugenol and solvent toluene, then drop to After reaching room temperature, 3.1 g of light yellow solid 2Si-OH was obtained with a yield of 48.2%.

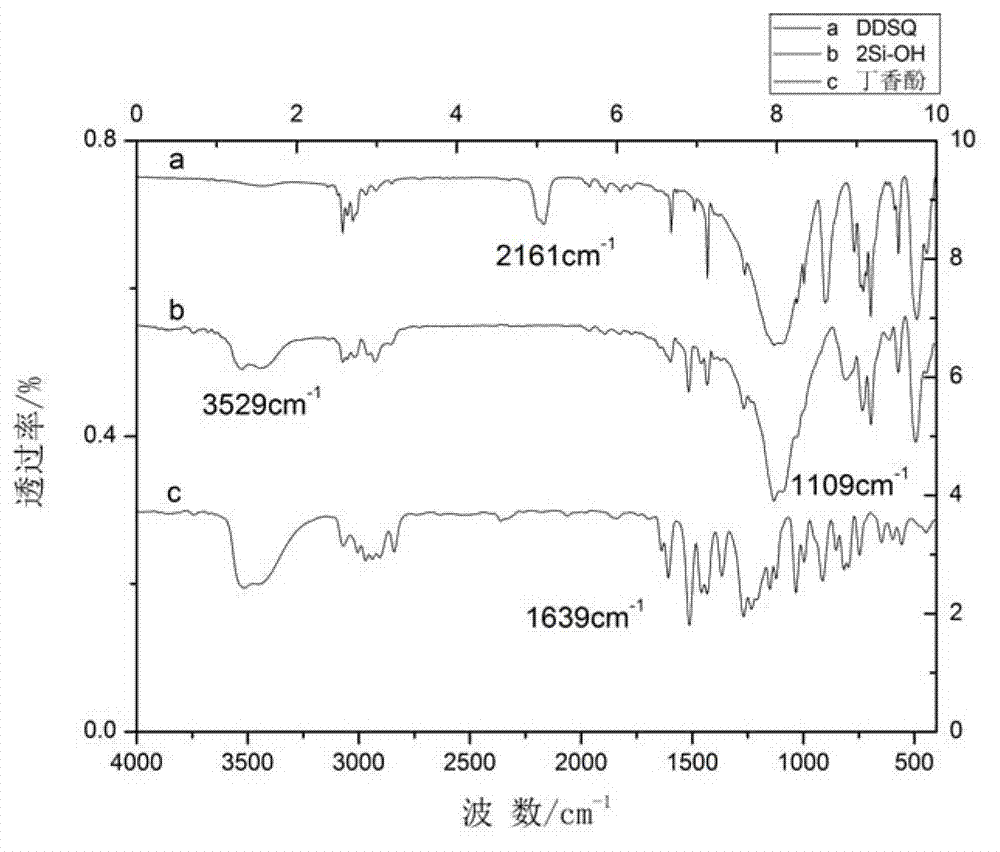

[0017] Use NicoletImpact410 Fourier transform infrared spectrometer to measure the infrared spectrum of 2Si-OH and eugenol, the scanning range is 4000~400cm -1 , resolution 4cm -1 , KBr tablet, see the results figure 1 . Depend on figure 1 It can be seen that the 1639cm in eugenol -1 The C=C bond absorption peak and the 2161cm in DDSQ -1 The Si-H bond absorption peak has disappeared in 2Si-OH, and...

Embodiment 2

[0021] Add DDSQ (5.0g, 0.004mol) and eugenol (1.48g, 0.009mol) into a nitrogen-protected container, add toluene (20mL) as a solvent in the system, raise the temperature to 65°C, and dropwise add Pt with a mass fraction of 0.3 0.2ml of Castel’s reagent, react at constant temperature for 12h and then cool down to room temperature, add the reaction mixture into a vacuum distillation device, and distill under reduced pressure at 90°C to remove unreacted eugenol and solvent toluene, and obtain 3.3g Pale yellow solid 2Si-OH, yield 51.3%.

Embodiment 3

[0023] Add DDSQ (5.0g, 0.004mol) and eugenol (1.64g, 0.01mol) into a nitrogen-protected container, add toluene (20mL) as a solvent in the system, raise the temperature to 70°C, and dropwise add Pt with a mass fraction of 0.3 0.2ml of Castel’s Reagent, react at constant temperature for 12h and cool down to room temperature, add the reaction mixture into a vacuum distillation device, and distill under reduced pressure at 90°C to remove unreacted eugenol and solvent toluene, and obtain 3.4g Pale yellow solid 2Si-OH, yield 53.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com