Long-narrow trench mask plate for vapor plating

A mask plate, narrow and long technology, which is applied in the field of long and narrow trench mask plates for evaporation, can solve the problems of not being able to reach the substrate, and achieve the effects of improving service life, reducing costs, and avoiding deformation of the plate surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

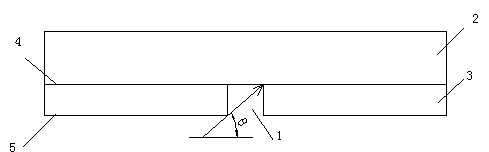

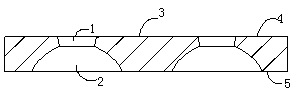

[0036] A 50μm-thick slit trench mask for evaporation, such as figure 2The shape shown is a rectangular metal plate, including the ITO surface in contact with the indium tin oxide (ITO) surface and the evaporation surface. The openings on the ITO surface coincide with the centers of the openings on the evaporation surface, and the groove-shaped openings are spaced apart from each other and parallel to each other; the area of the openings on the ITO surface is smaller than that on the evaporation surface.

[0037] Invar alloy is selected as the mask material, and the etching process is used to form half-cut from the ITO surface of the mask, such as Figure 5 The long and narrow opening 02, the depth of the opening 02 is 15 μm, and the lateral dimension of the opening 02 is 70 μm; it is formed by etching from the evaporation surface 5 of the mask plate as Figure 5 The middle opening 01 is narrow and long, and the centers of the openings on both sides are coincident. The ...

Embodiment 2

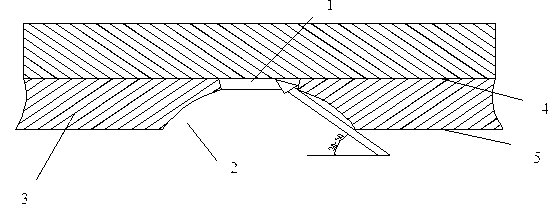

[0041] A long and narrow trench mask for evaporation, the transverse section is as follows figure 2 As shown, the thickness is 50 μm, and the shape is a quadrilateral metal plate, including two surfaces of the ITO surface 4 and the evaporation surface 5 that are in contact with the indium tin oxide (ITO) surface. The mask plate has a through ITO surface and the evaporation surface The size of the grid-shaped openings 1 on the ITO surface is smaller than the size of the narrow groove-shaped openings 2 on the evaporation surface. Invar alloy is selected as the mask material, and the double-sided etching process is adopted. image 3 It is a schematic diagram of the cooperation between the mask plate and the ITO surface.

[0042] 4 etch from the ITO side of the mask to form as figure 2 Opening 1 on the ITO surface of the middle mask, the depth of opening 1 is 15 μm, and the lateral dimension is 70 μm, etched from the evaporation surface 5 of the mask to form figure 2 Opening...

Embodiment 3

[0045] A long and narrow groove mask plate for evaporation, with a thickness of 100 μm and a shape of a quadrilateral metal plate, including two surfaces of an ITO surface and an evaporation surface. The size of the opening on the ITO surface is smaller than that on the evaporation surface.

[0046] The long and narrow groove mask for evaporation is a quadrilateral nickel-cobalt alloy metal plate, the opening depth of the ITO surface of the mask is 25 μm, and the lateral dimension is 50 μm. The centers of the slot-shaped openings coincide, and the centers of the openings on the evaporation surface are symmetrical, with a depth of 75 μm and a lateral dimension of 100 μm, and the walls of the openings on the evaporation surface have a certain concave arc, forming an evaporation angle of 30°. By separately controlling the etching time of the ITO surface and the evaporation surface, the required depths of the ITO surface opening and the evaporation surface opening are obtained. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com