Magnesium alloy pickling activator, pickling method and product

A technology of pickling activation and magnesium alloy, applied in the field of pickling activator and pickling, can solve the problems of animal and plant damage, non-compliance with environmental protection requirements, excessive manpower and working hours, etc., achieve mild reaction, save manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In order to achieve the above object, the magnesium alloy pickling activator provided by the present invention is used for pickling and activating treatment of magnesium alloys. The magnesium alloy pickling activator uses water as a solvent and includes the following components calculated by concentration:

[0030] 5-sulfosalicylic acid 10g / L;

[0031] Potassium fluoride 5g / L.

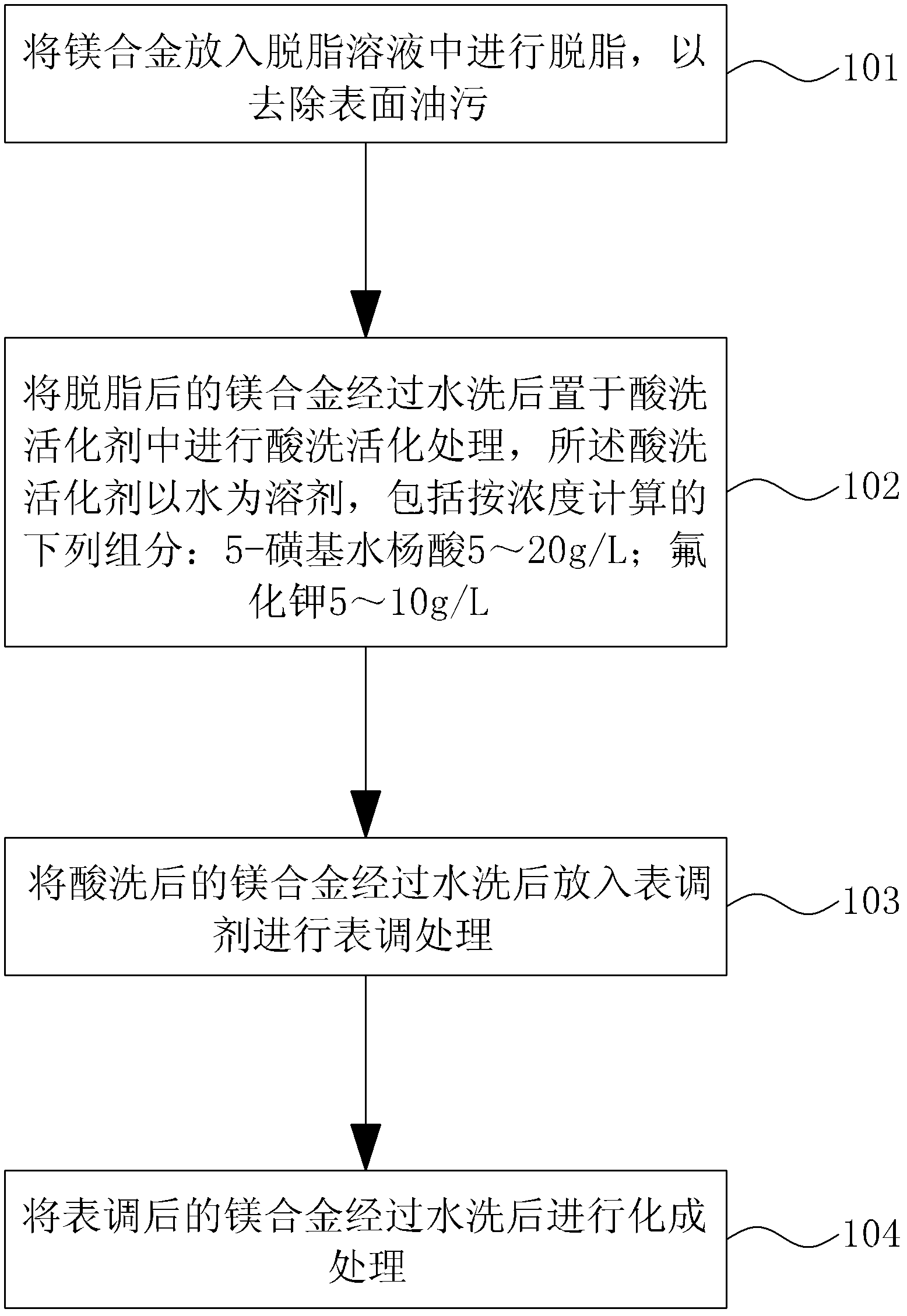

[0032] This embodiment also provides a magnesium alloy pickling method, the magnesium alloy pickling method comprising the following steps:

[0033] Step 101: Degreasing the magnesium alloy in a degreasing solution to remove surface oil, where the concentration of the degreasing solution is 30 g / L, the degreasing temperature is 60° C., and the degreasing time is 10 minutes;

[0034] Step 102: Wash the degreased magnesium alloy with water and place it in a pickling activator for pickling activation treatment. The pickling activator uses water as a solvent and includes the following components ca...

Embodiment 2

[0039] In order to achieve the above object, the magnesium alloy pickling activator provided by the present invention is used for pickling and activating treatment of magnesium alloys. The magnesium alloy pickling activator uses water as a solvent and includes the following components calculated by concentration:

[0040] 5-sulfosalicylic acid 15g / L;

[0041] Potassium fluoride 10g / L.

[0042] This embodiment also provides a magnesium alloy pickling method, the magnesium alloy pickling method comprising the following steps:

[0043] Step 101: Degreasing the magnesium alloy in a degreasing solution to remove surface oil, where the concentration of the degreasing solution is 30 g / L, the degreasing temperature is 60° C., and the degreasing time is 10 minutes;

[0044] Step 102: Wash the degreased magnesium alloy with water and place it in a pickling activator for pickling activation treatment. The pickling activator uses water as a solvent and includes the following components c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com