Synthesis method of titanium-silicon molecular sieve TS-1

A titanium-silicon molecular sieve, TS-1 technology, applied in the direction of crystalline aluminosilicate zeolite, etc., to achieve the effect of good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

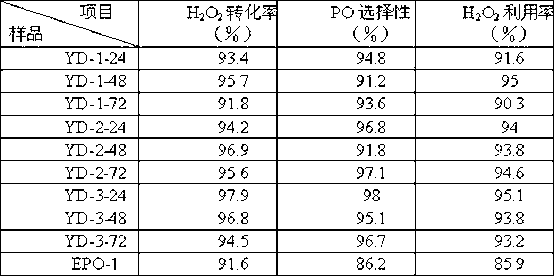

Embodiment 1

[0037] In this example, the feeding is carried out according to the following ratio: n (tetraethyl orthosilicate): n (tetrabutyl titanate): n (tetrapropylammonium bromide): n (H 2 O):n(IPA)=1:0.025:0.4:40:0.6. First, tetraethyl orthosilicate and distilled water were mixed under the condition of mechanical stirring, and dilute acid was added to adjust the pH value of the solution to 3.0, and the temperature was kept at 40° C. for 1 hour. Add the isopropanol solution of tetrabutyl titanate and dilute ammonia solution to the silicon source hydrolyzate at the same time, then add the template agent to the above hydrolyzate, and adjust the pH value of the solution to 13 with triethylamine solution, and then 40 °C Constant temperature 1h. The temperature of the reaction solution was raised to 85°C, and the alcohol was purged with nitrogen. Cool down and replenish water after alcohol catching. The obtained titanium-silicon precursor gel was divided into three sealed stainless steel...

Embodiment 2

[0039] In this example, the feeding is carried out according to the following ratio: n (tetrabutyl orthosilicate): n (tetraethyl titanate): n (tetrapropylammonium bromide): n (H 2 O):n(IPA)=1:0.03:0.3:60:0.8. Firstly, tetrabutyl orthosilicate and distilled water were mixed under the condition of mechanical stirring, and dilute acid was added to adjust the pH value of the solution to 3.0, and the temperature was kept at 40° C. for 1 hour. Add the isopropanol solution of tetraethyl titanate and dilute ammonia solution to the silicon source hydrolyzate at the same time, then add the templating agent to the above hydrolyzate, and adjust the pH value of the solution to 13 with triethylamine solution, then 40 °C Constant temperature 1h. The temperature of the reaction solution was raised to 85°C, and the alcohol was purged with nitrogen. Cool down and replenish water after alcohol catching. The obtained titanium-silicon precursor gel was divided into three sealed stainless steel ...

Embodiment 3

[0041] In this example, the feeding is carried out according to the following ratio: n (tetraethyl orthosilicate): n (tetrabutyl titanate): n (tetrapropyl ammonium hydroxide): n (H 2 O):n(IPA)=1:0.035:0.5:50:1. First, tetraethyl orthosilicate and distilled water were mixed under the condition of mechanical stirring, and dilute acid was added to adjust the pH value of the solution to 3.0, and the temperature was kept at 40° C. for 1 hour. Add the isopropanol solution of tetrabutyl titanate and dilute ammonia solution to the silicon source hydrolyzate at the same time, then add the templating agent to the above hydrolyzate, and adjust the pH value of the solution to 13 with triethylamine solution, and then 40°C Constant temperature 1h. The temperature of the reaction solution was raised to 85°C, and the alcohol was purged with nitrogen. Cool down and replenish water after alcohol catching. The obtained transparent titanium-silicon precursor gel was divided into three sealed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com