Anoxic humic filler filter tank and method for treating nitrogen containing degradation-resistant wastewater

A humic filler, refractory technology, applied in anaerobic digestion treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of unsatisfactory nitrification and denitrification function, easy blockage, large floor space, etc. , to achieve the effect of simple structure, large saturated hydraulic permeability coefficient and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

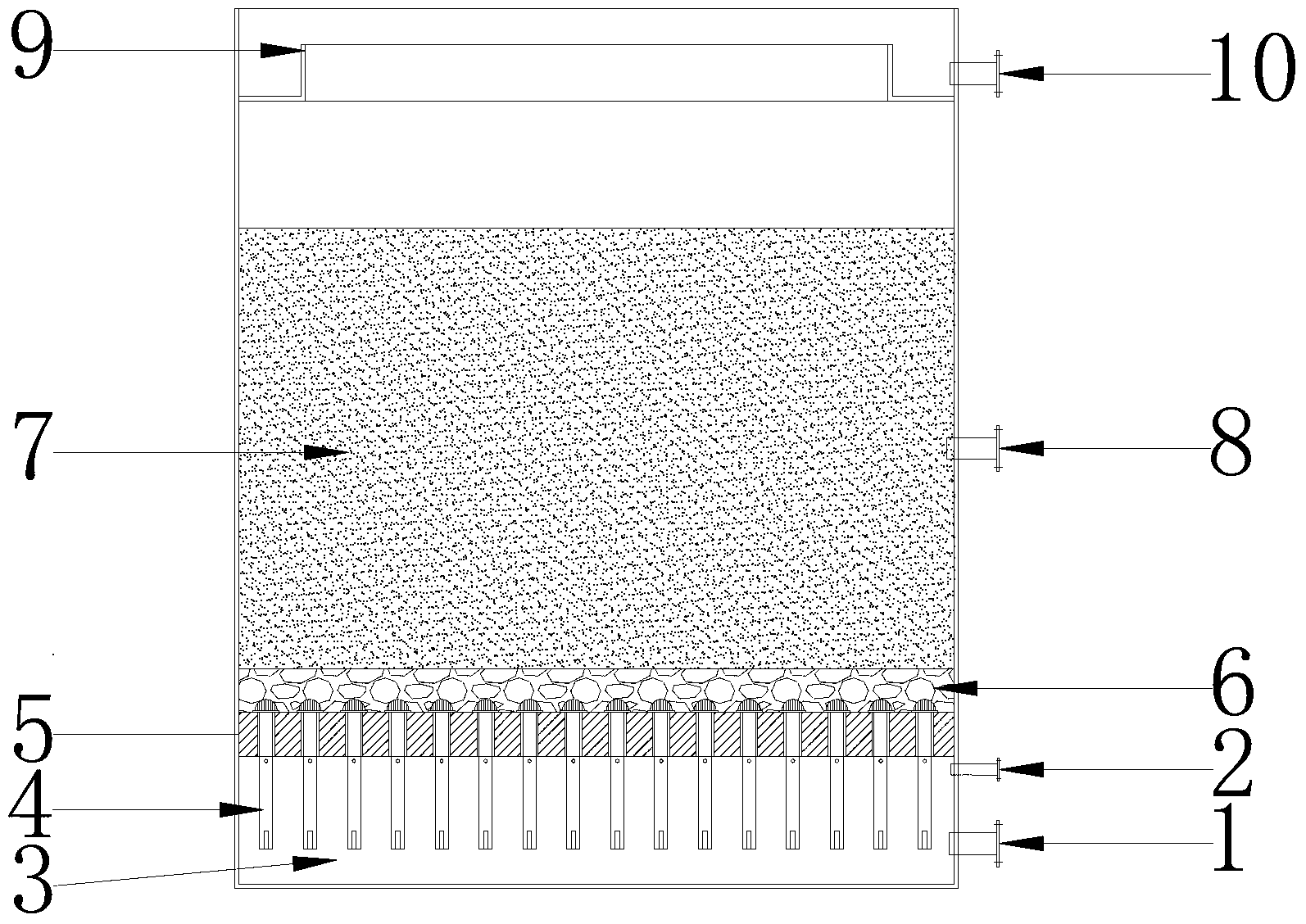

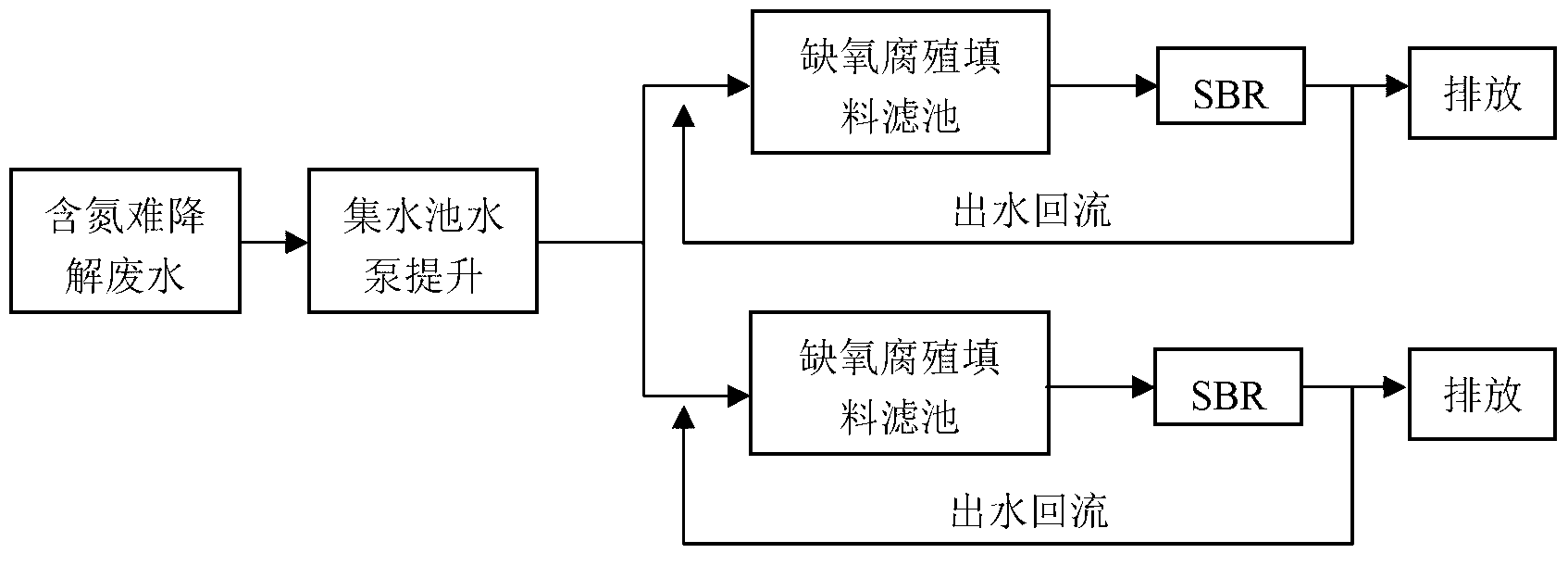

[0036] equipment such as figure 1 As shown, a filter tank with anoxic humic fillers includes a tank body, a water inlet pipe 1, a water distribution chamber 3, a supporting layer 6, a filler layer 7, a filler dosing pipe 8 and a drain pipe 10, and also includes an air inlet pipe 2, Long handle filter head 4, water distribution orifice plate 5 and overflow weir 9, water distribution chamber 3 is located at the bottom of the pool body; water inlet pipe 1 and air intake pipe 2 are connected to water distribution chamber 3; The upper part is the water distribution hole plate 5, the supporting layer 6 and the packing layer 7; the long handle filter head 4 passes through the water distribution hole plate 5, one end is connected with the supporting layer 6, and the other end is inserted into the water distribution chamber 3; the supporting layer 6 It is composed of natural pebbles or gravel; the filler feeding pipe 8 is connected to the filler layer 7 on one side of the pool body; th...

Embodiment 2

[0044] Same as Example 1, the difference is that the thicknesses of the four layers of natural gravel in the support layer 6 are 30mm, 30mm, 40mm, and 100mm from top to bottom, and the total thickness is 200mm. The height of the water distribution chamber 3 is 500 mm; the height of the packing layer 7 is 1000 mm; the height of the top of the packing layer 7 from the overflow weir 9 is 700 mm. The number of filter heads arranged is 56 / m 2 . In step B), 160 kg of slurry-like fresh peat filler is added to the filler layer 7 each time. In step D), the feeding time of each compressed air is 5min.

[0045] Process conditions and parameters: The influent water in this example is pretreated tannery wastewater, which has been treated for chromium removal and desulfurization. COD in influent water quality Cr The total nitrogen is 1250mg / L, the total nitrogen is 472mg / L, and the ammonia nitrogen is 225mg / L. The ambient temperature is 25°C, and the influent filtration rate is 3m / d. ...

Embodiment 3

[0048] Same as Example 1, the difference is that the thicknesses of the four layers of natural gravel in the support layer 6 are 30mm, 30mm, 40mm, and 100mm from top to bottom, and the total thickness is 200mm. The height of the water distribution chamber 3 is 450 mm; the height of the packing layer 7 is 1700 mm; the height of the top of the packing layer 7 from the overflow weir 9 is 630 mm. The number of filter heads arranged is 60 / m 2 . In step B), 240 kg of slurry-like fresh peat filler is added to the filler layer 7 each time. The feeding time of each compressed air in step D) is 10min.

[0049] Process conditions and parameters: The influent water in this example is pretreated tannery wastewater, which has been treated for chromium removal and desulfurization. COD in influent water quality Cr The total nitrogen is 906mg / L, the total nitrogen is 367mg / L, and the ammonia nitrogen is 139mg / L. The ambient temperature is 25°C, and the influent filtration rate is 6m / d.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com