Device and method for preparing sustainable-released antibacterial real-silk braided suture line

A technology for preparing devices and sutures, which is applied in textiles and papermaking, textile material processing, and continuous processing of textile materials. It can solve the problems of antibacterial performance decline, complicated operation, and environmental pollution, and achieve uniform dryness and compact structure. , the effect of gap reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

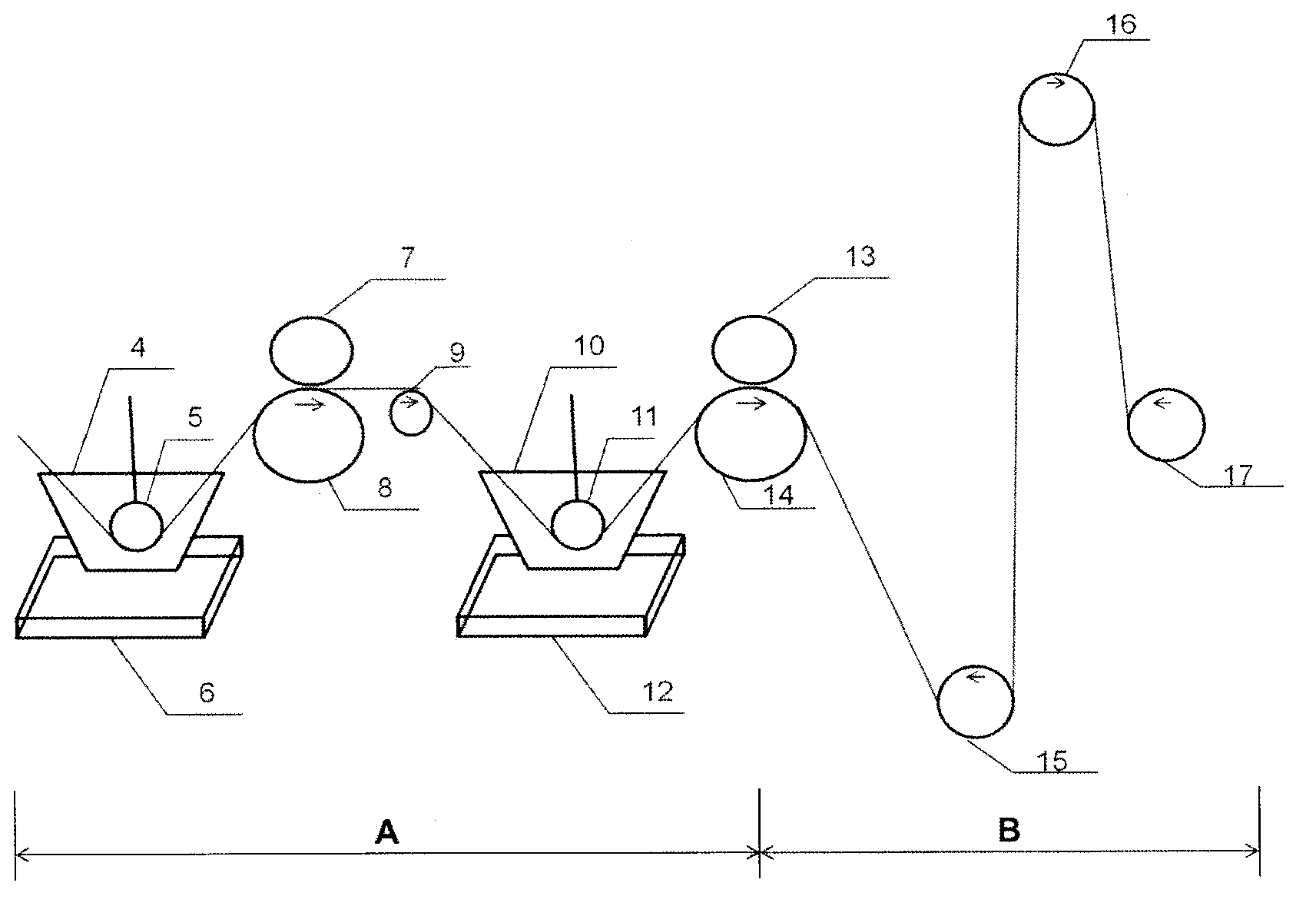

[0026] Such as figure 2 As shown, it is a schematic structural diagram of the preparation device of the antibacterial silk braided suture of the present invention, and the preparation device of the antibacterial silk braided suture is composed of a coating area A and a drying area B. The coating area A includes the first impregnation roll 5, the first pressure roll, the first guide roll 9, the second impregnation roll 11 and the second pressure roll, and the drying area B includes the second guide roll 15, the first Three guide rollers 16 and cylinder 17, the first dipping roller 5 is arranged in the first dipping tank 4, the first dipping tank 4 is arranged on the first heating device 6, and the first pressure roller is formed by the rubber roller 7 and the first pressure roller. The first stainless steel roller 8 under the first rubber roller 7 is composed of the second dipping roller 11 located in the second dipping tank 10, the second dipping tank 10 is located on the sec...

Embodiment 2

[0035] Such as figure 2 As shown, it is a schematic structural diagram of the preparation device of the antibacterial silk braided suture of the present invention, and the preparation device of the antibacterial silk braided suture is composed of a coating area A and a drying area B. The coating area A includes the first impregnation roll 5, the first pressure roll, the first guide roll 9, the second impregnation roll 11 and the second pressure roll, and the drying area B includes the second guide roll 15, the first Three guide rollers 16 and cylinder 17, the first dipping roller 5 is arranged in the first dipping tank 4, the first dipping tank 4 is arranged on the first heating device 6, and the first pressure roller is formed by the rubber roller 7 and the first pressure roller. The first stainless steel roller 8 under the first rubber roller 7 is composed of the second dipping roller 11 located in the second dipping tank 10, the second dipping tank 10 is located on the sec...

Embodiment 3

[0043] Such as figure 2 As shown, it is a schematic structural diagram of the preparation device of the antibacterial silk braided suture of the present invention, and the preparation device of the antibacterial silk braided suture is composed of a coating area A and a drying area B. The coating area A includes the first impregnation roll 5, the first pressure roll, the first guide roll 9, the second impregnation roll 11 and the second pressure roll, and the drying area B includes the second guide roll 15, the first Three guide rollers 16 and cylinder 17, the first dipping roller 5 is arranged in the first dipping tank 4, the first dipping tank 4 is arranged on the first heating device 6, and the first pressure roller is formed by the rubber roller 7 and the first pressure roller. The first stainless steel roller 8 under the first rubber roller 7 is composed of the second dipping roller 11 located in the second dipping tank 10, the second dipping tank 10 is located on the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com