Preparation method of graphene radiating fins

A technology of graphene and heat sink, which is applied in the field of microelectronic packaging, can solve problems that affect the electrical performance, mechanical strength and reliability of the chip, reduce the stability of the chip, and increase the error rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

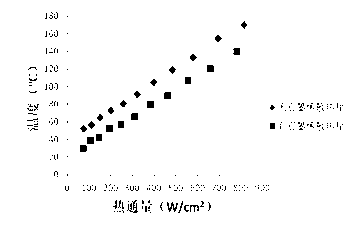

Image

Examples

Embodiment 1

[0011] (1) Deposit a layer of copper with a thickness of 1 micron on the surface of silicon dioxide by conventional electron beam evaporation method, and the purity of copper is 99.9%.

[0012] (2) Pass acetylene, hydrogen and argon into the reaction chamber of the Aixtron Black Magic deposition system, react at 900 degrees Celsius for 5-10 minutes, and grow graphene on the surface of silicon dioxide deposited with copper by chemical vapor deposition , The flow ratio of acetylene and hydrogen is 1:2 to 1:4, and the flow rate of acetylene is 5~10 standard cubic centimeters per minute (sccm).

[0013] (3) After cooling, spin-coat a layer of 300nm polymethyl methacrylate on the copper surface.

[0014] (4) Use 30% ferric chloride to etch copper for 20 minutes.

[0015] (5) Transfer the graphene spin-coated with polymethyl methacrylate to the target chip.

[0016] (6) The polymethyl methacrylate was removed with acetone, and finally the graphene heat sink was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com