Thin film transistor, manufacturing method thereof, array substrate and display device

A technology of thin film transistors and substrates, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, and electric solid-state devices. It can solve the problems of reducing the performance of Oxide TFT, not simple enough structure, and complicated process flow, and achieve simplified TFT structure, good electrical performance, The effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

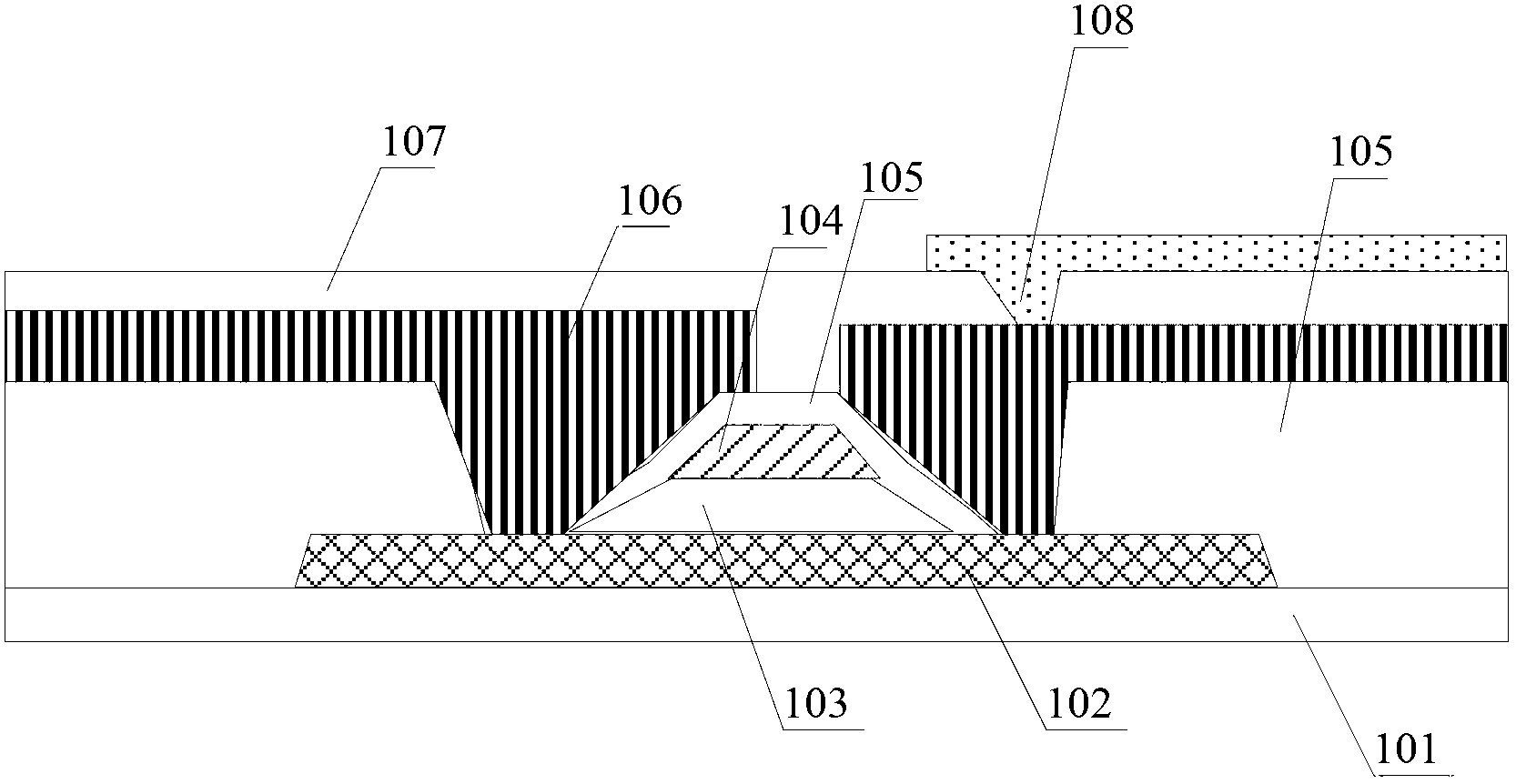

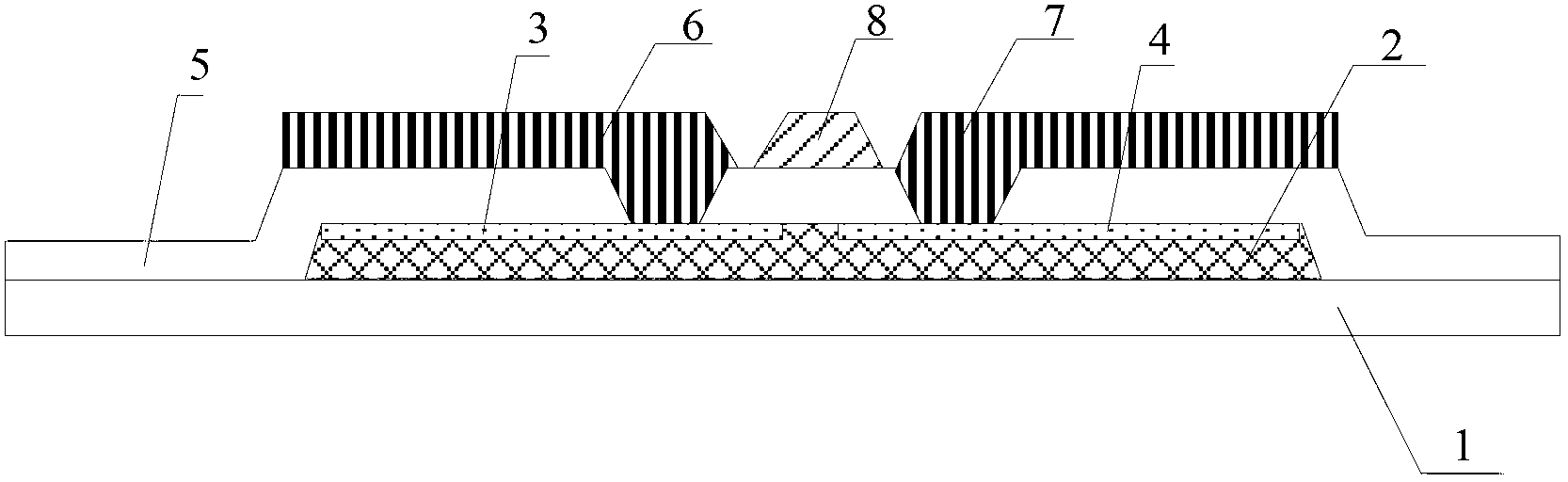

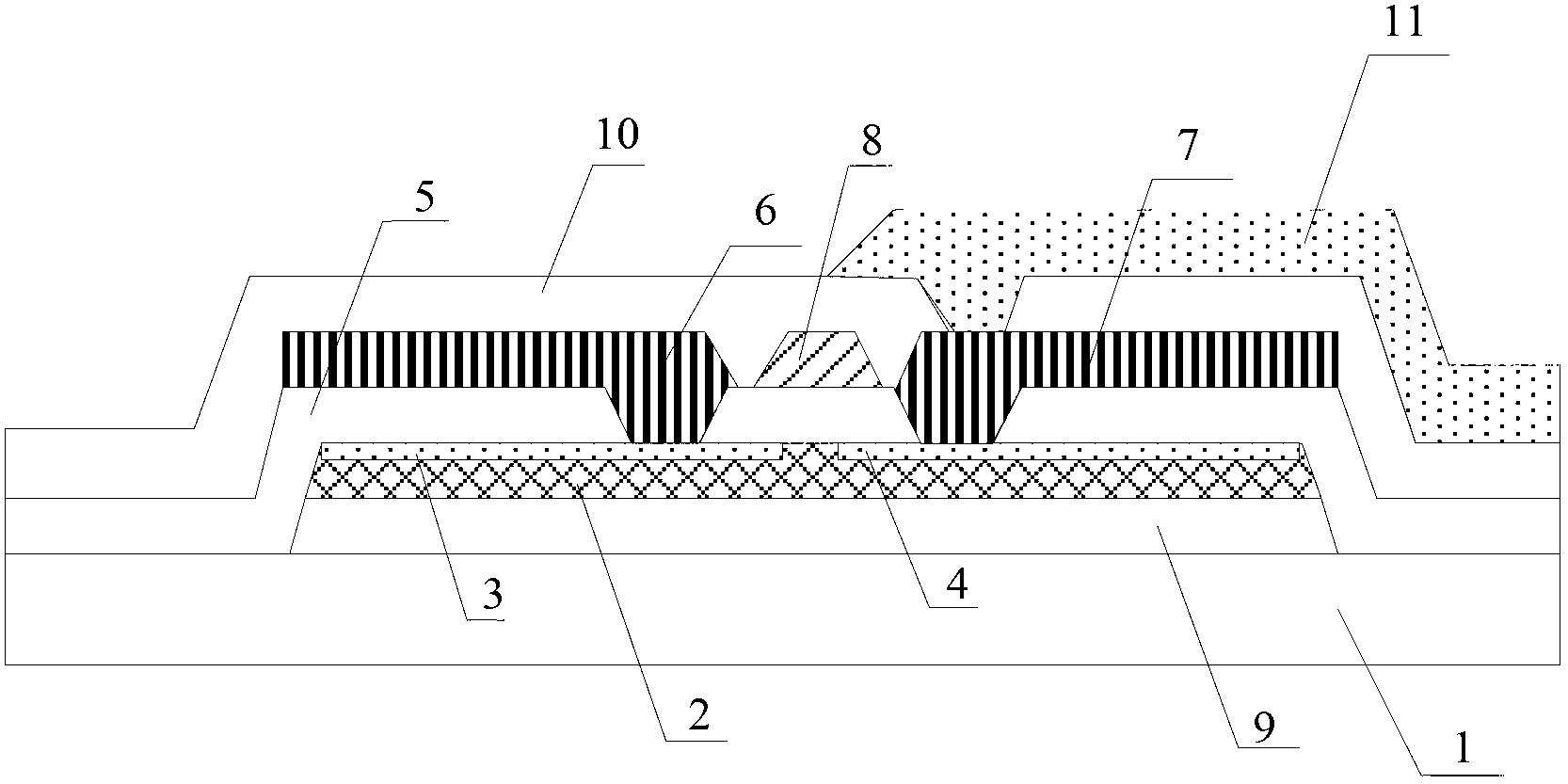

[0061] Embodiments of the present invention provide a thin film transistor and a manufacturing method thereof, an array substrate and a display device, so as to provide a TFT with a simple structure and better performance.

[0062] The embodiment of the present invention simplifies the structure of the TFT by making the source, the drain and the gate of the TFT in the same layer, and the process of making the TFT adopts a 5Mask process, which simplifies the manufacturing process of the TFT. The active layer is provided with a first contact layer connected to the source and a second contact layer connected to the drain to avoid the generation of non-channel high-resistance regions, and to avoid the gap between the gate and the source or between the gate and the drain. The formation of parasitic capacitance between them ensures the good electrical performance of TFT.

[0063] The TFT provided by the embodiment of the present invention will be specifically described below with refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com