White organic light emitting device with single light emitting layer structure

A technology for electroluminescent devices and light-emitting layers, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of complex preparation process, color drift, high cost, etc., achieve simplified device structure, reduce preparation cost, improve color Effects of Degree Stability and Efficiency Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

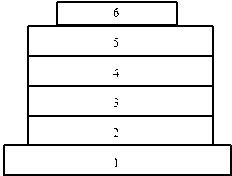

[0019] In this example, see figure 1 , a white light organic electroluminescent device with a single light-emitting layer structure, its structure is mainly composed of an ITO glass substrate 1, a hole transport layer 2, an electron blocking layer 3, a light-emitting layer 4, an electron transport layer 5 and a composite cathode 6, The light-emitting layer 4 is composed of a host-guest doping system to form a single-layer light-emitting layer. The host material constituting the light-emitting layer 4 is 1,3-bis (9-carbazolyl) benzene, that is, mCP, 2,6-bis(N-carbazolyl) pyridine , namely mCPy, the guest material constituting the light-emitting layer 4 is platinum [1,3-difluoro-4,6-di (2-pyridinyl) benzene] chloride, namely Pt-4, and the doping concentration of the guest material is 8 wt %, Its emission spectrum contains blue light peak and red light peak at the same time, blue light and red light are further mixed to form white light, and the thickness of the light-emitting la...

Embodiment 2

[0021] This embodiment is basically the same as Embodiment 1, especially in that:

[0022] In this embodiment, the host material in the light-emitting layer 4 is mCPy, and the guest material is platinum (II) [1, 3-difluoro-4, 6-di(2-pyridinyl) benzene] chloride, that is, the FPt doping concentration is 12 wt%, the electron blocking layer material is TCTA, the electron transport layer material is 2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline), that is, BCP. The white light emitted by the organic electroluminescent device in this embodiment has high brightness, high efficiency, high color purity and stable chromaticity.

Embodiment 3

[0024] This embodiment is basically the same as the previous embodiment, and the special features are:

[0025] In this embodiment, the host material in the light-emitting layer 4 is mCP, and the guest material is platinum N^C2^N-[1,3-di(4-methoxy-pyrid-2-yl)-4,6-difluorobenzene]chloride , that is, PtL 26 Cl, the doping concentration is 20 wt%, the electron blocking layer material is TCTA, and the electron transport layer material is TPBI. The white light emitted by the organic electroluminescent device in this embodiment also has the characteristics of high brightness, high efficiency, high color purity and stable chromaticity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com