Ditetrahydrofurfuryl isophthalate-5-sulfonic acid and salt, preparation method and application thereof, and polylactic resin

A technology of ditetrahydrofurfuryl isophthalate and polylactic acid resin, applied in the field of preparation of polylactic acid resin, ditetrahydrofurfuryl isophthalate-5-sulfonic acid and its salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also discloses a preparation method of the ditetrahydrofurfuryl isophthalate-5-sulfonic acid, comprising the following steps:

[0041] Carrying out sulfonation reaction of isophthalic acid and sulfonating reagent to obtain 5-sulfoisophthalic acid;

[0042] The 5-sulfoisophthalic acid is acylated with an acylating agent, and then alcoholysed with tetrahydrofurfuryl alcohol to obtain ditetrahydrofurfuryl isophthalate-5-sulfonic acid.

[0043] In the process of preparing ditetrahydrofurfuryl isophthalate-5-sulfonic acid, the present invention uses isophthalic acid as a raw material to synthesize ditetrahydrofurfuryl isophthalate-5-sulfonic acid. According to the present invention, firstly, isophthalic acid is subjected to sulfonation reaction with a sulfonating agent to obtain 5-sulfoisophthalic acid. The sulfonating agent is preferably oleum, and the content of sulfur trioxide in the oleum is 20wt%-60wt%. The molar ratio of the sulfur trioxide to i...

Embodiment 1

[0062] Weigh 16.6 g of isophthalic acid, put it into a 250 mL three-necked round bottom flask equipped with a reflux condenser, add 25 mL of 20 wt % oleum, and heat the oil bath to 185 ° C for 6 hours under stirring conditions. After the reaction is over, remove the oil bath and cool to room temperature, dilute the reaction system, and cool sufficiently to precipitate 5-sulfoisophthalic acid. The excessive waste sulfuric acid was filtered off, and the obtained solid 5-sulfoisophthalic acid was added into a 250 mL three-neck round bottom flask. Add 70mL of thionyl chloride into a three-necked round-bottomed flask, heat and reflux at 80°C for 5 hours, after the reaction, transfer the reaction flask to an ice-water bath to cool, slowly add 15mL of tetrahydrofurfuryl alcohol dropwise to carry out the alcoholysis reaction, during the alcoholysis process Control the reaction temperature to 30°C. Ditetrahydrofurfuryl isophthalate-5-sulfonic acid can be obtained after separation and ...

Embodiment 2

[0066] Prepare ditetrahydrofurfuryl isophthalate-5-sulfonic acid according to the operation method described in Example 1. After the esterification reaction ends, add 40wt% potassium carbonate aqueous solution to the reaction system for neutralization, to pH After becoming neutral, filter and separate to obtain ditetrahydrofurfuryl isophthalate-5-potassium sulfonate.

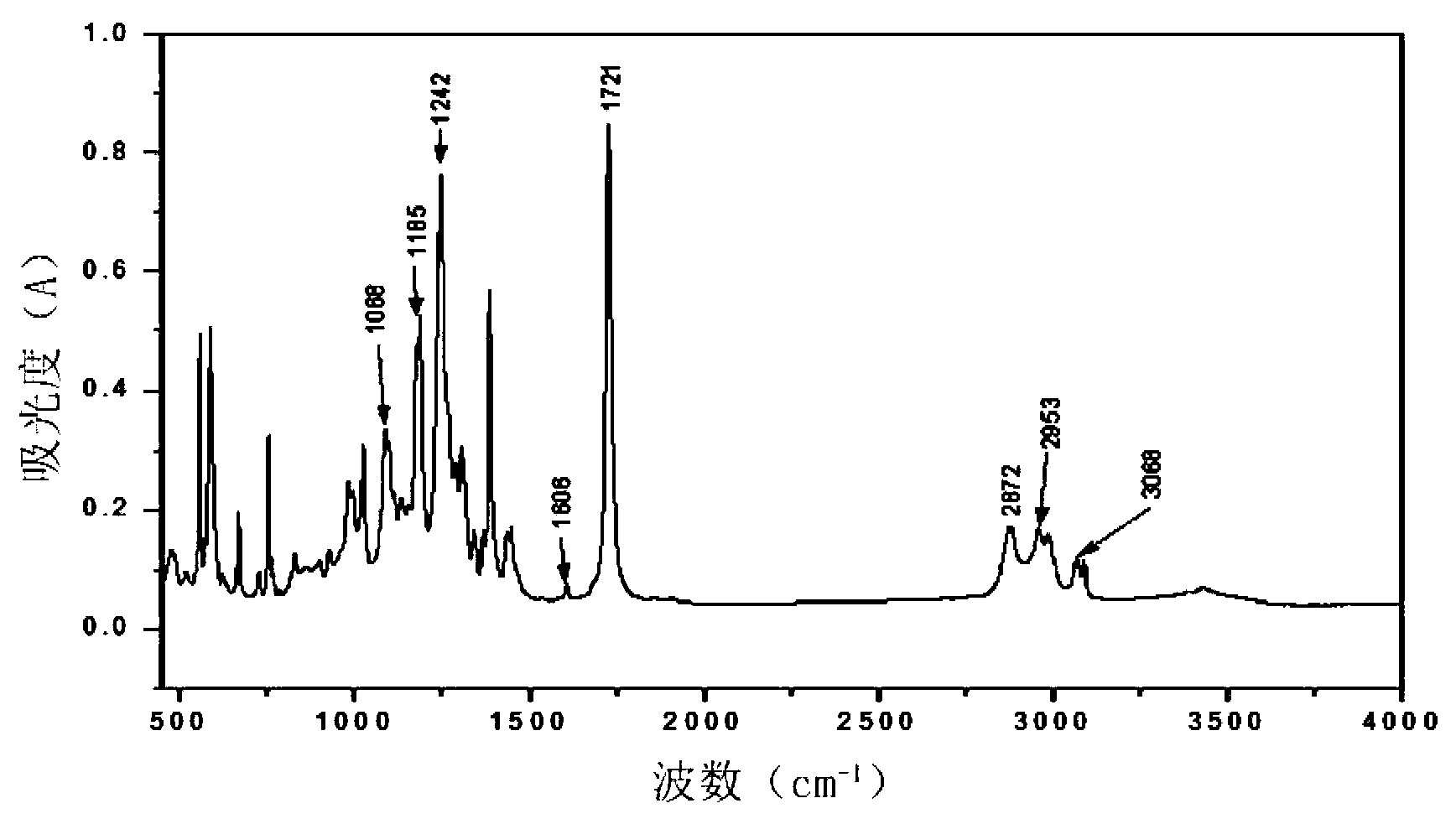

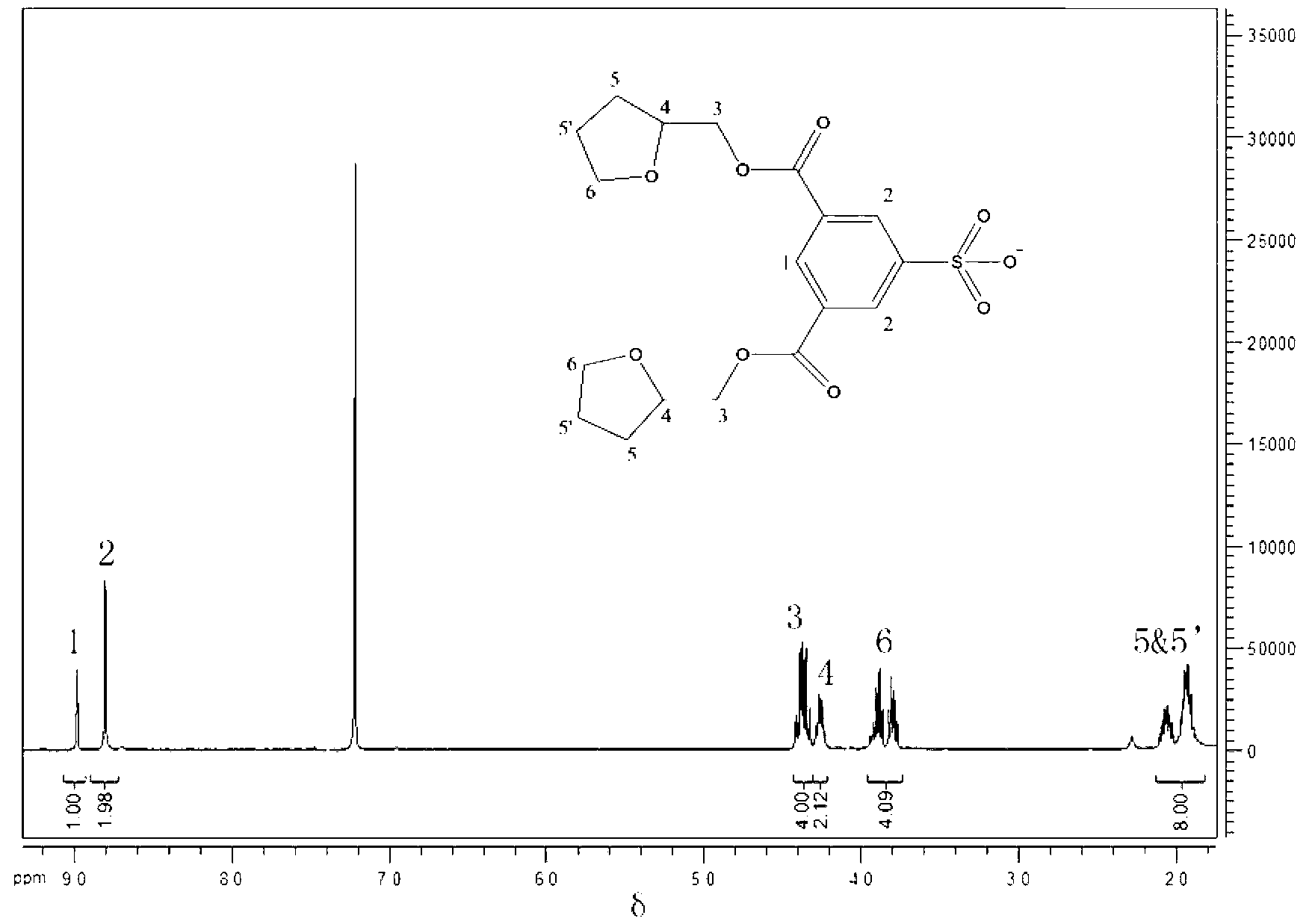

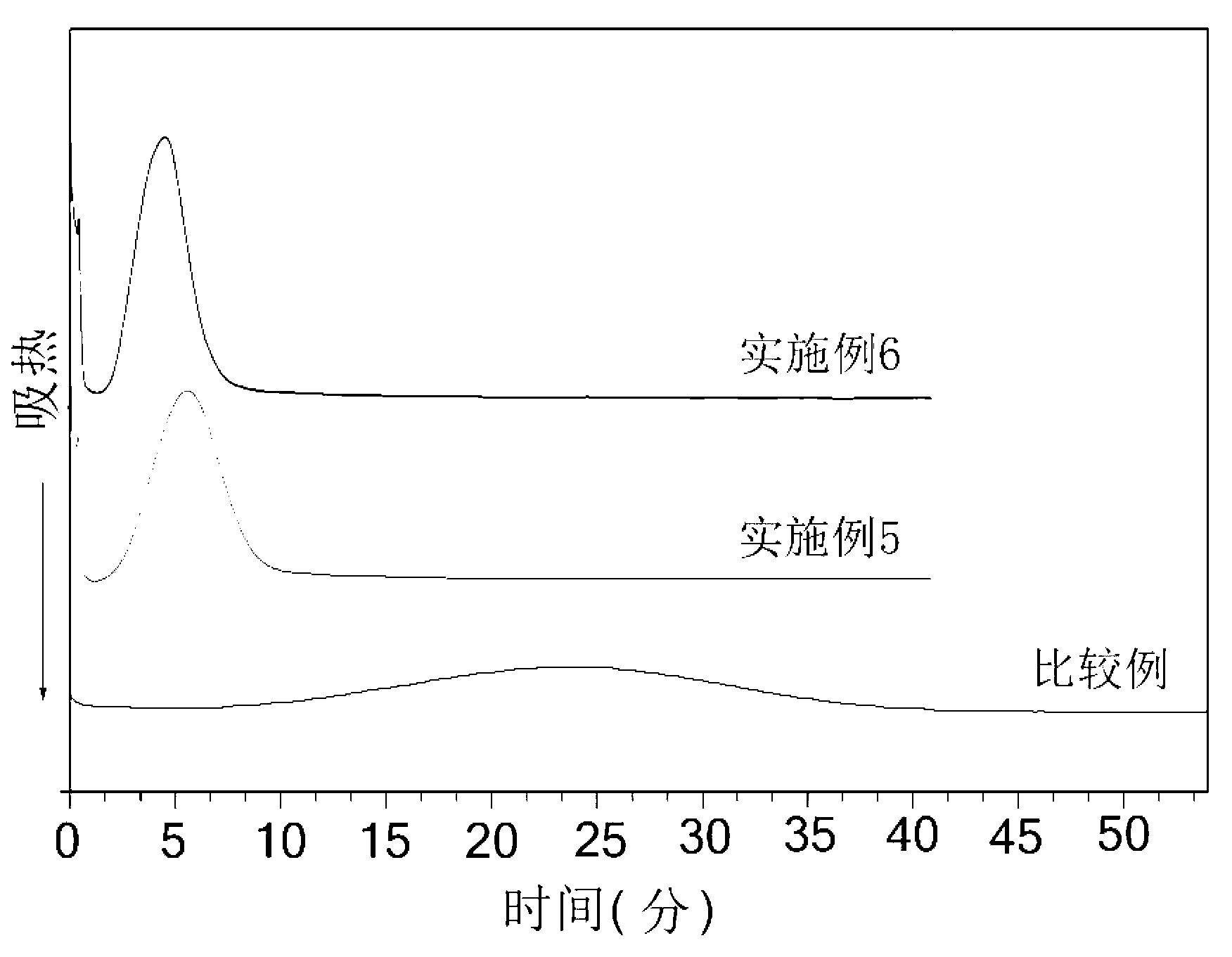

[0067] The ditetrahydrofurfuryl isophthalate-5-potassium sulfonate obtained is carried out by nuclear magnetic resonance and infrared spectrum analysis, and the results are as follows: figure 1 and figure 2 as shown, figure 1 For the infrared spectrogram of ditetrahydrofurfuryl isophthalate-5-potassium sulfonate prepared in Example 2 of the present invention, figure 2 For the ditetrahydrofurfuryl isophthalate-5-potassium sulfonate prepared in Example 2 of the present invention 1 H NMR spectrum. Depend on figure 1 It can be seen that 3068cm -1 The C-H stretching vibration peak of the benzene ring appears ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com