Method for producing crude tall oil by soap washing with calcium carbonate removal

A crude tall oil, calcium carbonate technology, applied in the production of fat, recycling technology, recovery of fat oil/fatty acid from waste, etc., can solve the problem of not mentioning the purification of concentrated brine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

comparative ) Embodiment 1

[0072] Basic Saponification and Tall Oil Recovery Process

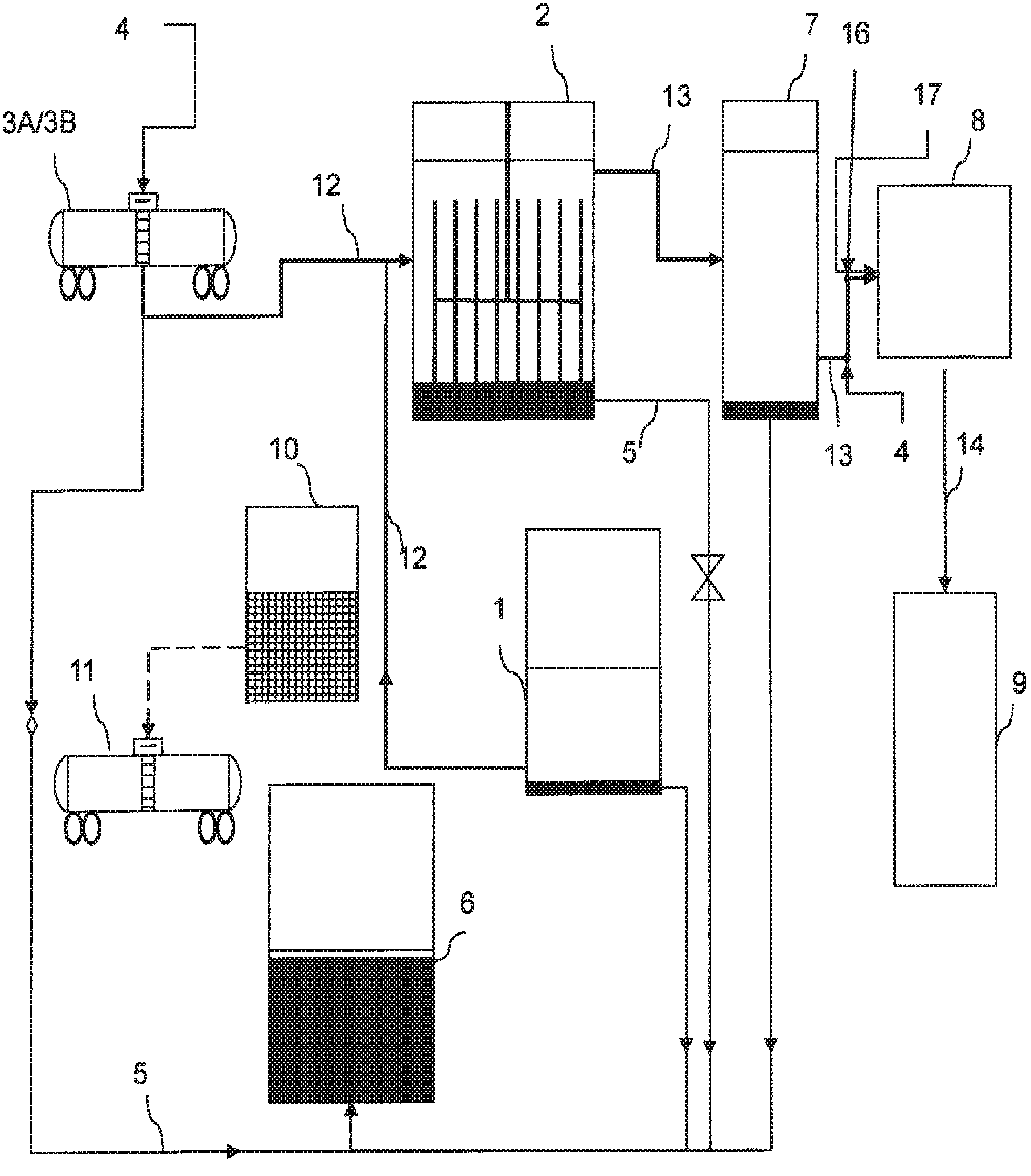

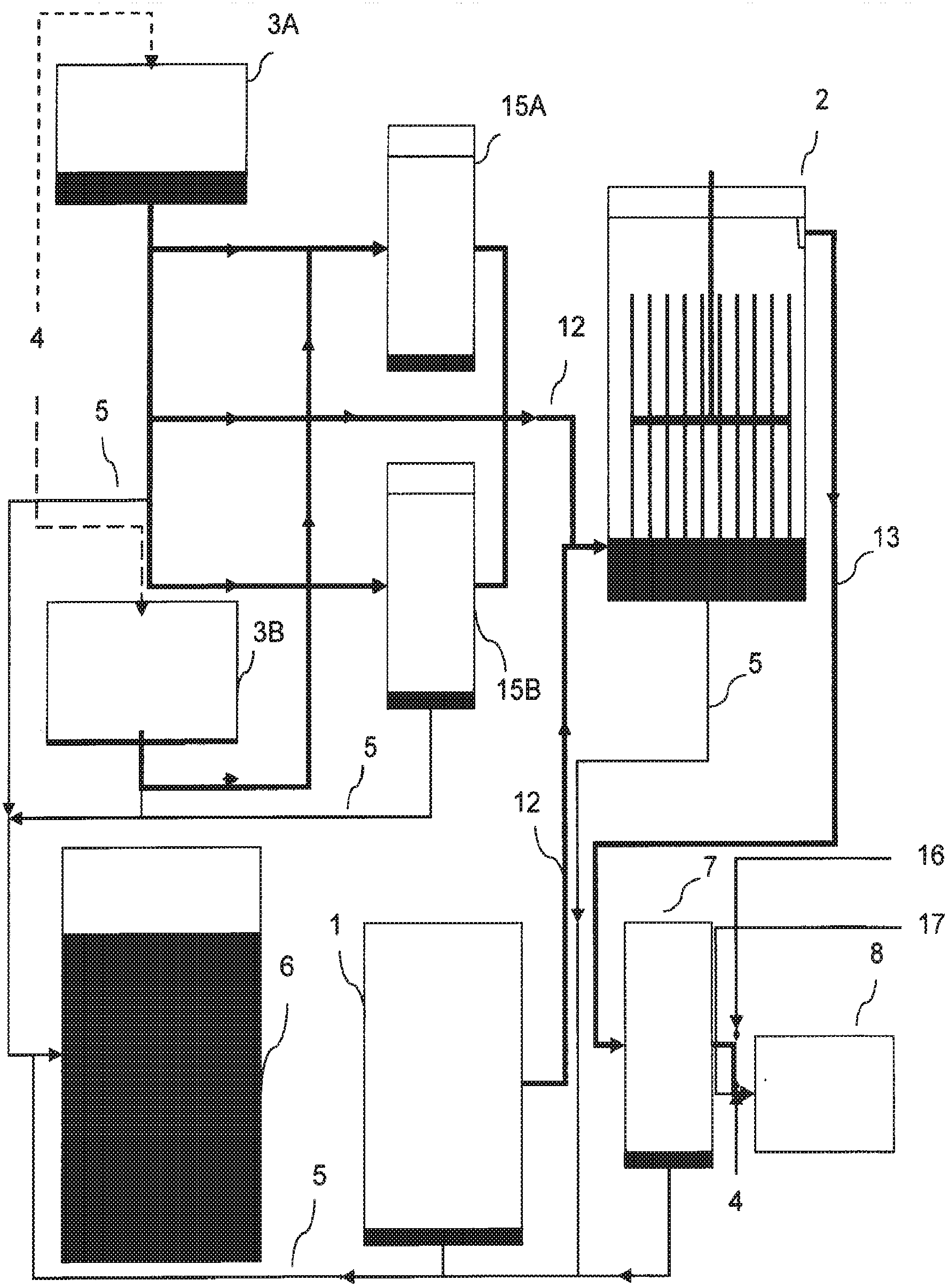

[0073] Black liquor soap is received from the main mill 1 and provided to the rake screen tank 2 together with black liquor soap in tank cars and rail cars received from other suppliers. The role of tank 2 is discussed below. refer to Figure 1-3 Might be helpful.

[0074] soap uninstall

[0075] refer to figure 1 , before the soap received from the rail cars and tank cars 3a / 3b is completely unloaded, the black liquor separated during transport to the bottom of these transport containers is drained and pumped to the main mill dilute black liquor storage system 6 . After the separated and drained liquid is removed, the soap can be pumped directly to tank 2 or into an intermediate storage tank and finally combined with the soap from the main mill before entering tank 2.

[0076] To assist in the pumping of viscous soaps from rail cars or tank cars, water is often added to the pump suction4. The added water red...

Embodiment 2

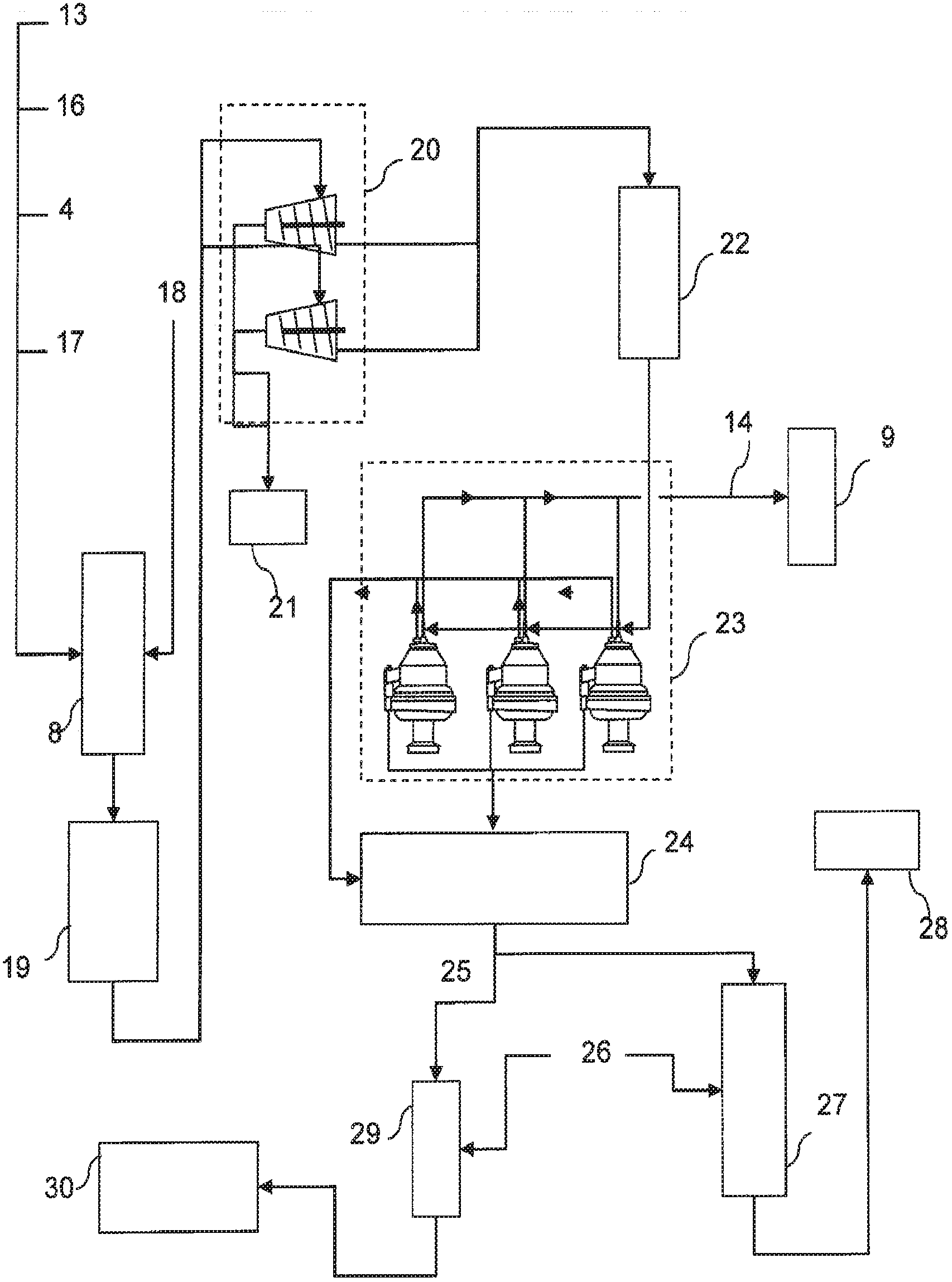

[0095] Soap wash test (see Figure 4-6 )

[0096] To test the invention, the water used in unloading tall oil soap was replaced with "clean" alkaline tall oil plant brine at about pH 12 from the causticizing unit 27 (here "clean" means low filterable in this example, this measured less than 30 ppm filterable solids and less than 0.6 wt% ligninate. The "clean" alkaline tall oil tested The ratio of factory brine wash medium to soap was about 0.25:1.00 by weight. The trial was run for 3 days, and about 2 of these days were considered necessary to ensure that any unwashed soap in the system was initially flushed out.

[0097] refer to Figure 6 , unlike the previous ones, in this embodiment the high solids shock stream from the jet centrifuge 23 is diverted from the influent brine collection tank 24 and collected in the agitated shock collection tank 34 (see Figure 6 ). About 10 gpm (40 L / min) of clean spent acid from brine collection tank 24 is sent to agitated impingement c...

Embodiment 3

[0117] Determination of (Total) Filterable Solids and Inorganic Filterable Solids in Cleaned Spent Acid (Adapted from TAPPI T635om-89)

[0118] (Total) Filterable Solids

[0119] Determination of clean spent acid filterable solids was performed as follows. Store the 5.5-cm G6 in a desiccator A glass fiber filter ring is added to an accurately weighed Buchner filter (approximately 5.8 cm inner diameter), and the Buchner filter and filter ring are accurately weighed on an analytical balance. The Buchner filter and glass fiber filter ring were placed on a 500-mL Erlenmeyer filter flask connected to a vacuum source.

[0120] Approximately 50 mL of a well-stirred clean spent acid sample was poured into a tared 100 mL beaker and the sample was accurately weighed.

[0121] After wetting the glass fiber ring in the Buchner filter with about 5 ml of deionized water, pour the cleaned spent acid sample in the beaker into the Buchner filter. Rinse the beaker several times with deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com