Composite phosphorous removal agent for sewage treatment and preparation method thereof

A technology of sewage treatment and phosphorus removal agent, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The problem of high phosphorus cost is achieved, and the effect of low treatment cost, convenient use and storage, and high phosphorus removal effect is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

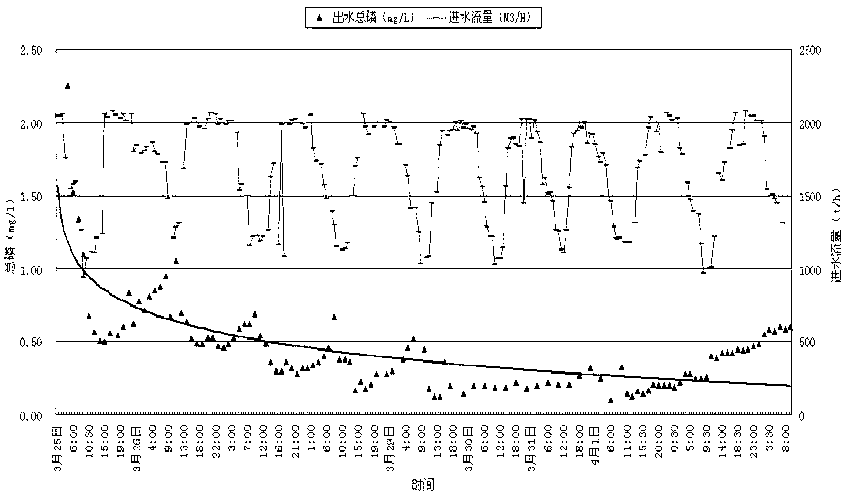

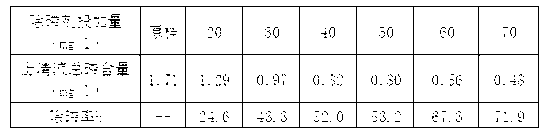

Image

Examples

Embodiment 1

[0026] Step 1: Put the aluminum processing waste with an alumina content greater than 80% in the acid solution, the mixing ratio of the aluminum processing waste and the acid solution is 0.6:1, carry out self-heating reaction under normal pressure stirring conditions, and control the temperature at 90°C ;

[0027] The acid solution is a mixed acid of sulfuric acid and hydrochloric acid, the mass fraction of sulfuric acid is 98%, the mass fraction of hydrochloric acid is 31%, and the proportion is 0.2:1.

[0028] Step 2: After two hours of reaction, add ferric chloride so that the molar ratio of iron and aluminum in the added material is 1:1.5, stir for 30 minutes, stop stirring, and stand still for 8 hours of polymerization.

[0029] Step 3: Extract the supernatant liquid in the compounding tank to prepare an aluminum oxide ferric sol solution containing aluminum, iron, sulfate, and chloride, and its alkalization degree is controlled at 30%;

[0030] Step 4: When the temperat...

Embodiment 2

[0033] Step 1: Put the aluminum processing waste with an alumina content greater than 80% in the acid solution, the mixing ratio of the aluminum processing waste and the acid solution is 0.75:1, carry out self-heating reaction under normal pressure stirring conditions, and control the temperature at 95°C ;

[0034] The acid solution is a mixed acid of sulfuric acid and hydrochloric acid, the mass fraction of sulfuric acid is 98%, the mass fraction of hydrochloric acid is 31%, and the proportion is 0.5:1.

[0035] Step 2: After reacting for two hours, add ferric chloride so that the molar ratio of iron and aluminum in the added material is 1:2.2, and then stop stirring after stirring for 30 minutes, and statically polymerize for 8 hours.

[0036] Step 3: extract the supernatant liquid in the compound pool to prepare an aluminum oxide ferric sol solution containing aluminum, iron, sulfate, and chloride, and its alkalinity is controlled at 45%;

[0037] Step 4: When the temperat...

Embodiment 3

[0040] Step 1: Put the aluminum processing waste with an alumina content greater than 80% in the acid solution, the mixing ratio of the aluminum processing waste and the acid solution is 0.9:1, carry out self-heating reaction under normal pressure stirring conditions, and control the temperature at 100°C ;

[0041] The acid solution is a mixed acid of sulfuric acid and hydrochloric acid, the mass fraction of sulfuric acid is 98%, the mass fraction of hydrochloric acid is 31%, and the proportion is 0.8:1.

[0042] Step 2: After reacting for two hours, add ferric chloride so that the molar ratio of iron and aluminum in the added material is 1:3, and then stop stirring after stirring for 30 minutes, and statically polymerize for 8 hours.

[0043] Step 3: Extract the supernatant liquid in the compounding pool to prepare an aluminum oxide ferric sol solution containing aluminum, iron, sulfate, and chloride, and its alkalization degree is controlled at 60%;

[0044] Step 4: When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com