Low carbon nitrogen ratio micro contaminated water nitrogen removal method

A technology with slightly polluted water and low carbon-to-nitrogen ratio, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low proliferation rate of autotrophic microorganisms and long hydraulic retention time HRT , sulfur consumption and other problems, to achieve the effect of reducing excessive sulfate ion content, short breeding time, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Concrete steps of the present invention are as follows:

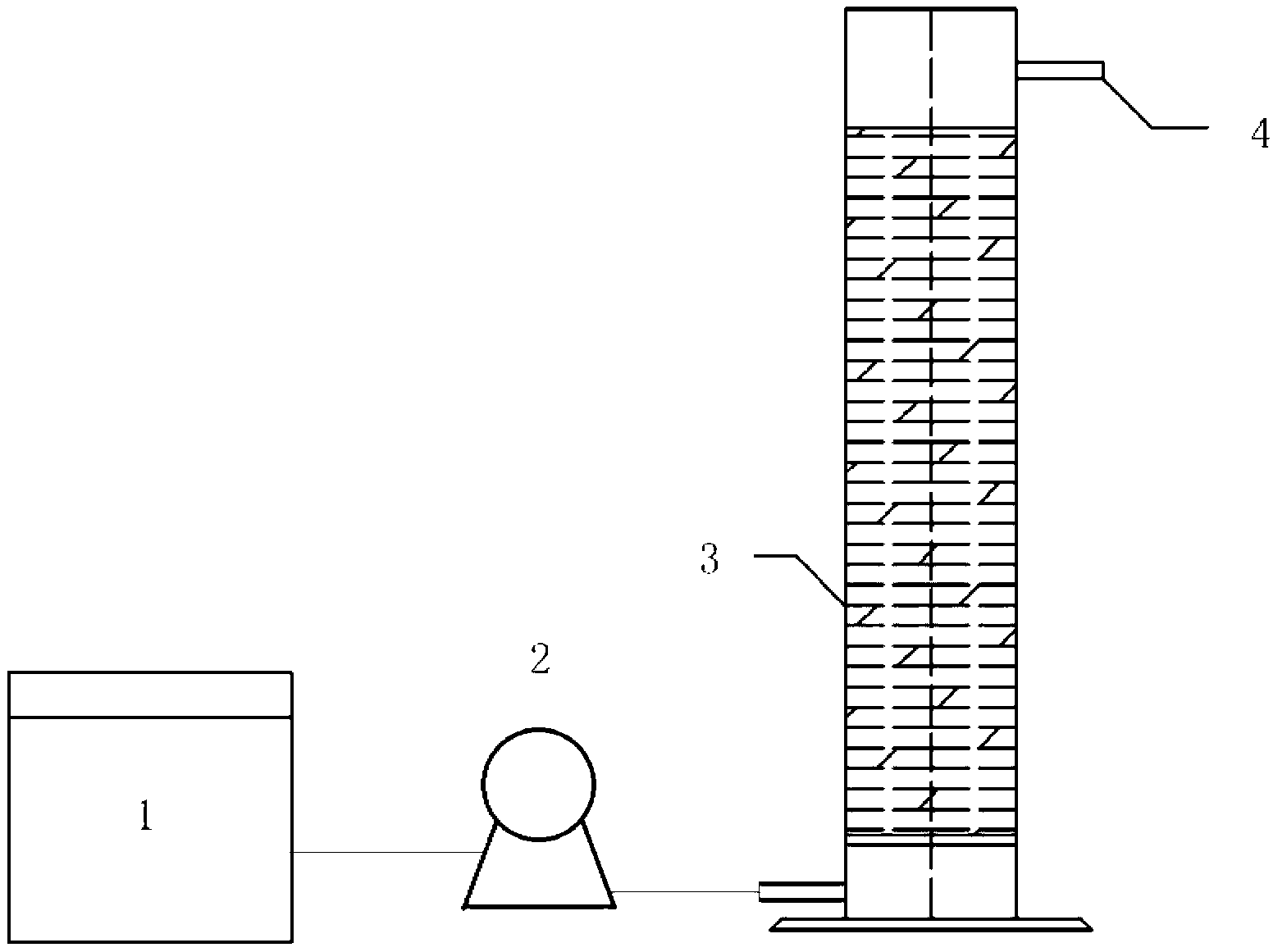

[0022] 1) Place composite denitrification filler in layers in the upward flow reactor (see attached picture), the composite denitrification filler is sulfur / limestone / forest waste, the volume ratio is 1:0.2~0.5:0.5~2, specifically sulfur The volume ratio of limestone / wood residue is 1:0.2:0.5, 1:0.2:1, 1:0.2:2, 1:0.5:0.5, etc.

[0023] The sulfur is melted and molded, and processed into a small cylinder with a bottom diameter of about 1-1.5 cm and a height of about 1-1.5 cm. The limestone is crushed into granules with a volume roughly equivalent to that of sulfur granules. Forest waste is discarded in forestry production. shavings, plant residues, etc.

[0024] 2) Start the first stage, inoculate the filler with anaerobic sludge equal to the volume of the filler, set the start-up HRT to 8 h, pump the raw water into the upward flow reactor, and continuously feed Thiobacillus denitrification The medium was used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com