Glass production device and forming process method

A technology for production equipment and glass, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of unstable waviness quality, restricting technology development, and difficulty in crystallization, and achieve excellent thermal expansion coefficient properties and thermal expansion coefficient. Low, the effect of preventing devitrification and crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

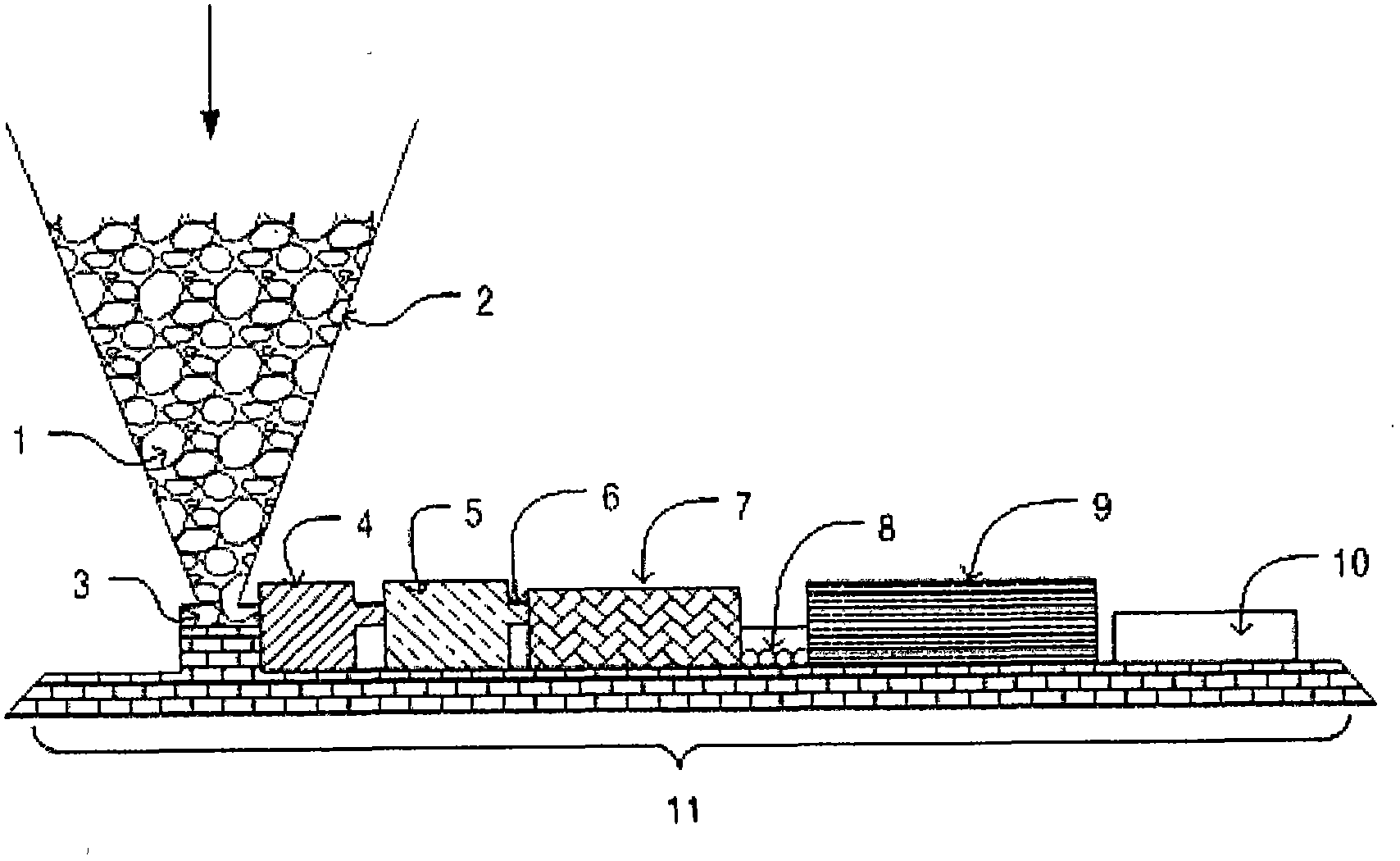

[0068] S101: Mix the raw materials sodium oxide, aluminum oxide, silicon oxide, magnesium oxide and calcium oxide, put them into the silo 2, enter the mixing device 3 along with the hopper, and the mixing device 3 stirs them. Wherein, by weight percentage, the content of sodium oxide is 6%, the content of aluminum oxide is 25%, the content of silicon oxide is three times that of calcium oxide, and the content of calcium oxide is 1.4 times that of magnesium oxide.

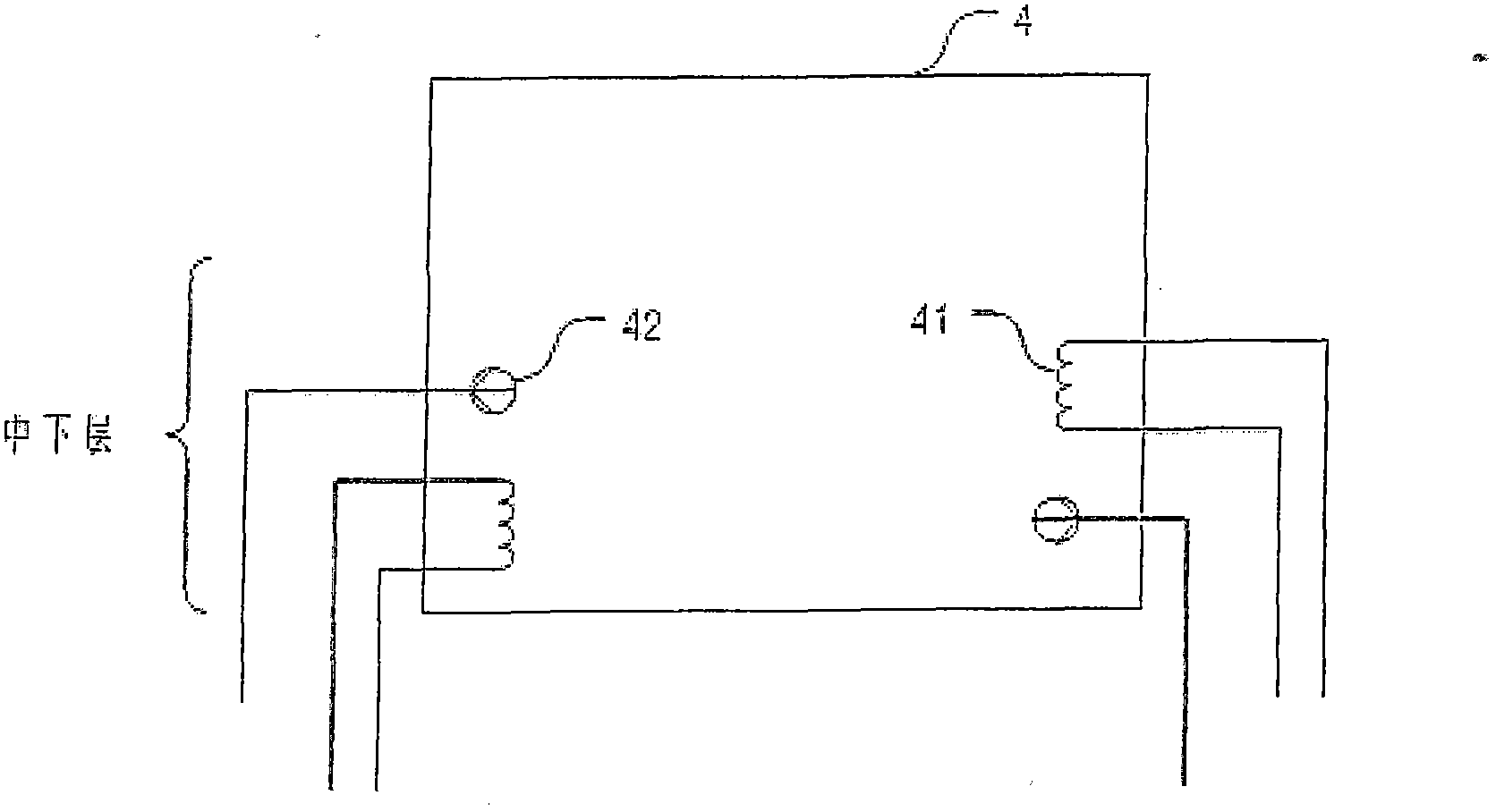

[0069] S102: Install 40 electric heating devices and temperature measuring devices with a distance of 1.5m in the middle and lower layers of the melting device 4, and install 40 electric heating devices and temperature measuring devices with a distance of 1.5m in the middle and lower layers of the cooling unit 5 The device and the electric heating device and the device for measuring temperature are installed in the range of 0.6m at the two corners of the left and right sides in the direction of the tin kiln in the mi...

Embodiment 2

[0083] S201: Mix sodium oxide, aluminum oxide, silicon oxide and calcium oxide, put them into the silo 2, enter the mixing device 3 along with the silo, and the mixing device 3 stirs them. Wherein, by weight percentage, the content of sodium oxide is 0.1%, the content of aluminum oxide is 15%, the content of silicon oxide is 4 times that of calcium oxide, and the content of calcium oxide is 1.8 times that of magnesium oxide.

[0084] S202: Install 160 electric heating devices and temperature measuring devices with a distance of 0.5m in the middle and lower layers of the melting device 4; install 160 electric heating devices and temperature measuring devices with a distance of 0.5m in the middle and lower layers of the cooling unit 5 The device and the electric heating device and the device for measuring temperature are installed in the range of 0.3m at the two corners of the left and right sides in the direction of the tin kiln in the middle and lower layers of the cooling unit...

Embodiment 3

[0098] S301: Mix sodium oxide, aluminum oxide, silicon oxide and calcium oxide, put them into the silo 2, enter the mixing device 3 along with the silo 2, and the mixing device 3 stirs them. Wherein, by weight percentage, the content of sodium oxide is up to 14%, the content of aluminum oxide is up to 10%, the content of silicon oxide is up to 7 times that of calcium oxide, and the content of calcium oxide is up to 1 time that of magnesium oxide. .

[0099] S302: Install 110 electric heating devices and temperature measuring devices with a distance of up to 1m in the middle and lower layers of the melting device 4, and install 110 electric heating devices and temperature measuring devices with a distance of up to 1m in the middle and lower layers of the cooling unit 5 The device and the electric heating device and the device for measuring temperature are installed in the range of 1m at the two corners of the left and right sides of the cooling unit in the direction of the tin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com