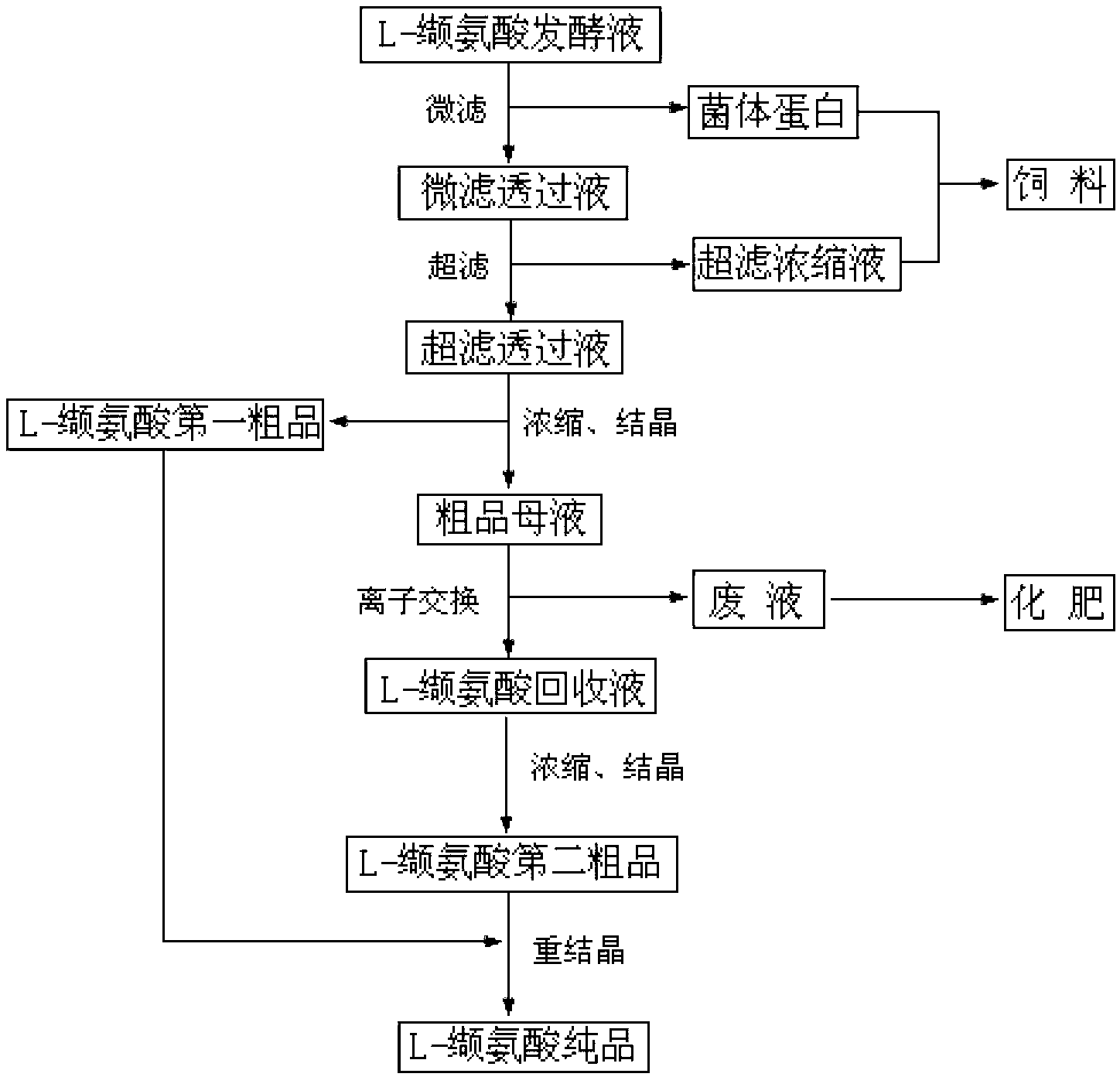

Method for separating and extracting L-valine from broth with high efficiency

A technology of valine and fermentation broth, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of incomplete decolorization of ordinary activated carbon, limited product purity, and many impurities, and achieve automatic control and clean production, environmental protection, and high economic value-added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Microfiltration treatment

[0038] Inject the L-valine fermentation broth into an organic membrane microfiltration separation system with a membrane pore size of 50-100nm, control the operating temperature to 40°C, the operating pressure to 0.6MPa, and the average membrane flux to 73L / m 2 h, after removing the bacteria and some proteins in the fermentation broth, the microfiltration permeate and bacterial protein are obtained; the microfiltration permeate is transparent and clear, without visible suspended matter, and the light transmittance is ≥ 90%. After drying, it can be used as a high-protein feed additive; among them, the yield of L-valine after microfiltration treatment is 95.0%, and the protein removal rate is 91.7%;

[0039] 2. Ultrafiltration treatment

[0040]The microfiltration permeate is injected into the organic membrane ultrafiltration separation system with a membrane pore size of 1-10nm, the operating temperature is controlled at 35°C, the operatin...

Embodiment 2

[0052] 1. Microfiltration treatment

[0053] Inject the L-valine fermentation broth into an organic membrane microfiltration separation system with a membrane pore size of 50-100nm, control the operating temperature to 30°C, the operating pressure to 0.4MPa, and the average membrane flux to 75L / m 2 h, after removing the bacteria and some proteins in the fermentation broth, the microfiltration permeate and bacterial protein are obtained; the microfiltration permeate is transparent and clear, without visible suspended matter, and the light transmittance is ≥ 90%. After drying, it can be used as a high-protein feed additive; among them, the yield of L-valine after microfiltration treatment is 93.5%, and the protein removal rate is 93.5%;

[0054] 2. Ultrafiltration treatment

[0055] The microfiltration permeate is injected into the organic membrane ultrafiltration separation system with a membrane pore size of 1-10nm, the operating temperature is controlled at 20°C, the operati...

Embodiment 3

[0067] 1. Microfiltration treatment

[0068] Inject the L-valine fermentation broth into an organic membrane microfiltration separation system with a membrane pore size of 50-100nm, control the operating temperature at 20°C, the operating pressure at 1.0MPa, and the average membrane flux at 76L / m 2 h, after removing the bacteria and some proteins in the fermentation broth, the microfiltration permeate and bacterial protein are obtained; the microfiltration permeate is transparent and clear, without visible suspended matter, and the light transmittance is ≥ 90%. After drying, it can be used as a high-protein feed additive; among them, the yield of L-valine after microfiltration treatment is 95.2%, and the protein removal rate is 91.2%;

[0069] 2. Ultrafiltration treatment

[0070] The microfiltration permeate is injected into the organic membrane ultrafiltration separation system with a membrane pore size of 1-10nm, the operating temperature is controlled at 45°C, the operati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com