Thin film type optical collimator on basis of surface plasmon polaritons

A surface plasmon and light collimation technology, applied in optics, instruments, optical components, etc., can solve problems such as increased design costs and complex device structures, and achieve the effects of improving divergence angle, small size, and expanding beam width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

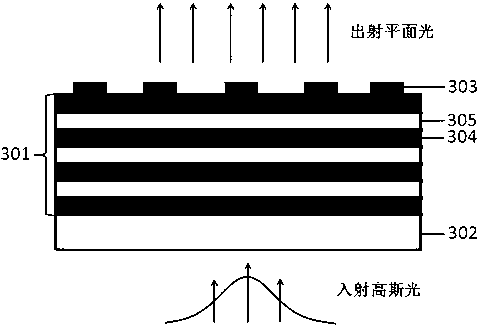

[0048] The wavelength of the Gaussian light source is taken as 595 nm, the metal is taken as silver, and the medium is taken as molybdenum oxide. After analysis, we get:

[0049] 1) When the ratio of the silver metal film 304 and the molybdenum oxide dielectric film 305 is 1:1.5 to 1:0.5, Gaussian light can obtain collimated light through the film light shaper; further, the silver metal film 304 and the molybdenum oxide dielectric film 305 The best effect is when the ratio is 1:1.2, that is, the transmittance is relatively high and the side lobes are relatively weak.

[0050] 2) When the thickness of the silver metal film 304 and the molybdenum oxide dielectric film 305 is 5-15 nm, Gaussian light can obtain collimated light through the film light shaper; further, the thickness of the silver metal film 304 and the molybdenum oxide dielectric film 305 are respectively Works best at 11 nm and 13.2 nm.

[0051] 3) When the total number of layers of the silver metal thin film 304...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com