Method for preparing lanthanum and iron composite absorbing phosphorous removal agent

A composite adsorption and dephosphorization agent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low phosphorus affinity, few adsorption sites, and low removal rate No high problems, to achieve the effect of fast adsorption rate, increase load capacity, and strengthen the transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

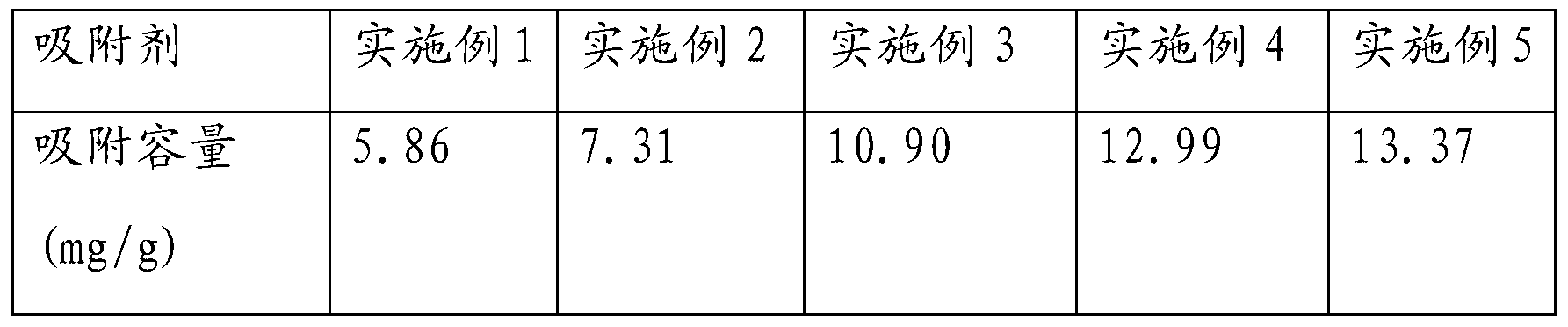

Examples

Embodiment 1

[0026] This embodiment relates to a method for preparing a lanthanum-iron composite adsorption dephosphorization agent, the method comprising the following steps:

[0027] Step 1, configure 20mL total molar concentration as ferric nitrate and ferric nitrate mixed solution of 0.1mol / L when the molar ratio of iron lanthanum ion is 9:1;

[0028] Step 2, cut the activated carbon fiber into 0.4-0.6cm cubes, wash with water for several times, soak in deionized water, filter and dry;

[0029] Step 3, weigh 0.2 g of the activated carbon fiber obtained in step 2, add ferric nitrate and ferric nitrate mixed solution, and use ultrasonic treatment to oscillate and mix for 10 minutes, and take out the solid;

[0030] Step 4, immersing the solid obtained in step 3 in 20% ammonia solution (pH=10) for 2 hours, so that the mixed metal ions are deposited on the carrier ACF;

[0031] In step 5, the solid obtained in step 4 is taken out and washed several times with deionized water until the pH ...

Embodiment 2

[0033] This embodiment relates to a method for preparing a lanthanum-iron composite adsorption dephosphorization agent, the method comprising the following steps:

[0034] Step 1, when configuring 20mL total molar concentration as 0.2mol / L ferric nitrate and ferric nitrate mixed solution when being 7:3 with iron lanthanum ion molar ratio;

[0035] Step 2, cut the activated carbon fiber into 0.4-0.6cm cubes, wash with water for several times, soak in deionized water, filter and dry;

[0036] Step 3, weighing 0.2 g of the activated carbon fiber obtained in step 2, adding ferric nitrate and ferric nitrate mixed solution, ultrasonic treatment and shaking and mixing for 20 minutes, and taking out the solid;

[0037] Step 4, immersing the solid obtained in step 3 in 25% ammonia solution (pH=12) for 5 hours, so that the mixed metal ions are deposited on the carrier ACF;

[0038] Step 5: Take out the solid obtained in step 4 and wash it several times with deionized water until the pH...

Embodiment 3

[0040] This embodiment relates to a method for preparing a lanthanum-iron composite adsorption dephosphorization agent, the method comprising the following steps:

[0041] Step 1, when configuring 20mL total molar concentration as 0.3mol / L ferric nitrate and ferric nitrate mixed solution when the iron lanthanum ion molar ratio is 1:1;

[0042] Step 2, cut the activated carbon fiber into 0.4-0.6cm cubes, wash with water for several times, soak in deionized water, filter and dry;

[0043] Step 3, weighing 0.2 g of the activated carbon fiber obtained in step 2, adding ferric nitrate and ferric nitrate mixed solution, using ultrasonic treatment to vibrate and mix for 30 minutes, and taking out the solid;

[0044] Step 4, immerse the solid obtained in step 3 in 28% ammonia solution (pH=13) for 3 hours, so that the mixed metal ions are deposited on the carrier ACF;

[0045] In step 5, the solid obtained in step 4 is taken out and washed several times with deionized water until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com