Heat-conducting medium

A heat-conducting medium and anti-oxidant technology, applied in the field of heat conduction, can solve problems affecting the normal use of heating systems, corrosion of plastic seals, corrosion of pipes, etc., and achieve the effects of no corrosion, elimination of corrosion, and prevention of frost cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

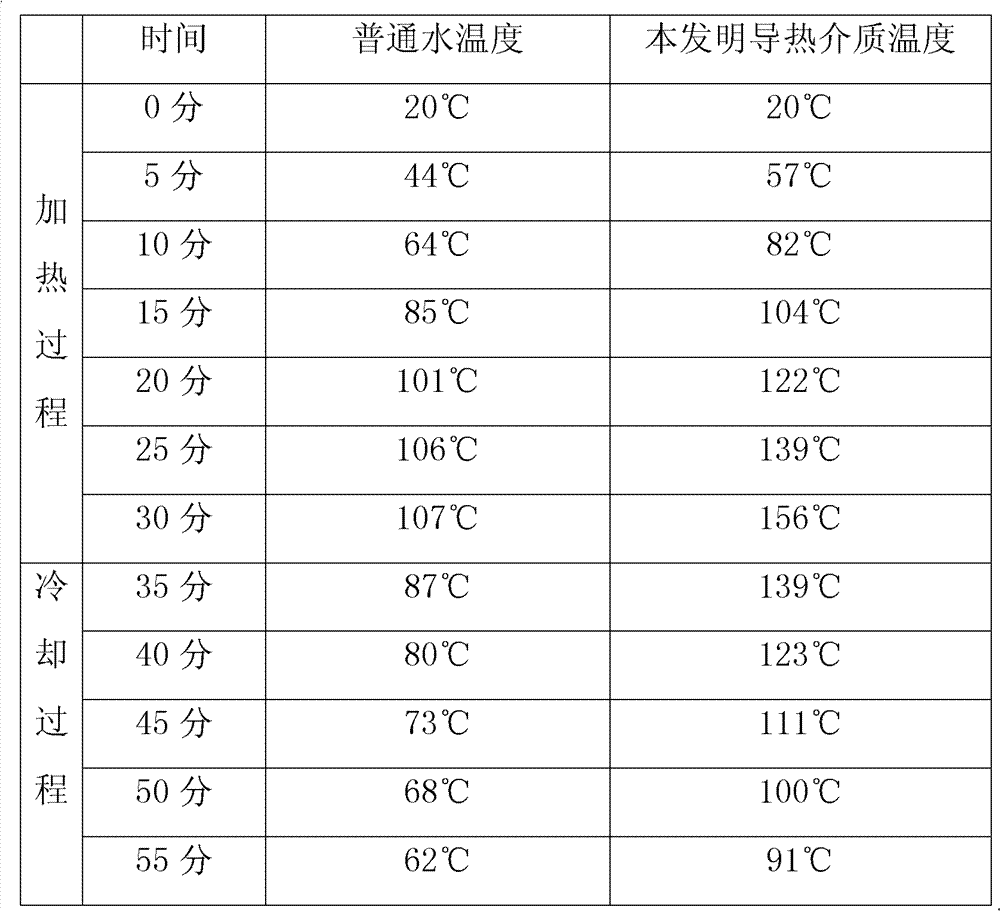

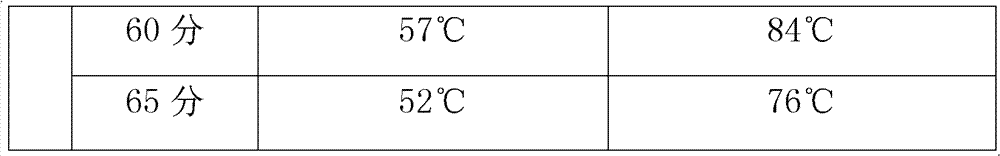

Image

Examples

Embodiment 1

[0014] The heat conduction medium provided by the present invention is mainly composed of ethylene glycol or propylene glycol plus pure water, the ratio of the mixed liquid is 65-90 parts by weight of ethylene glycol or propylene glycol, and 15-30 parts by weight of pure water, and the weight part of sodium benzoate is added thereto 0.55-1.0 parts by weight, 0.45-1.0 parts by weight of methyl benzotriazine, 0.65-1.0 parts by weight of sodium molybdate, 0.25-0.5 parts by weight of potassium hydroxide, 0.8-1.5 parts by weight of methanol, 0.8-1.2 parts by weight of silicone oil, 0.25-0.5 parts by weight of triethanolamine or monoethanolamine or diethanolamine, 0.95-1.3 parts by weight of sodium nitrate or magnesium nitrate, 0.2-3 parts by weight of stearic acid, and 0.2-0.5 parts by weight of antioxidant.

Embodiment 2

[0016] The invention provides a heat conducting medium, comprising the following components in parts by weight: 65-90 parts of ethylene glycol or propylene glycol, 15-30 parts of pure water, 0.55-1.0 parts of sodium benzoate, 0.45-1.0 parts of methyl benzotriazepam File, 0.65-1.0 parts of sodium molybdate, 0.25-0.5 parts of potassium hydroxide, 0.8-1.2 parts of methanol, 1.0-1.2 parts of silicone oil, 0.25-0.5 parts of triethanolamine or diethanolamine or monoethanolamine, 0.95-1.3 parts of sodium nitrate or Magnesium nitrate, 2.3-2.8 stearic acid, 0.3-0.4 antioxidant.

Embodiment 3

[0018] The heat conduction medium provided by the present invention is mainly composed of ethylene glycol plus pure water, the ratio of the mixed liquid is 65-90 parts by weight of ethylene glycol, 15-30 parts by weight of pure water, and 0.55-1.0 parts by weight of sodium benzoate is added thereto. , 0.45-1.0 parts by weight of methyl benzotriazine, 0.65-1.0 parts by weight of sodium molybdate, 0.25-0.5 parts by weight of potassium hydroxide, 0.8-1.5 parts by weight of methanol, 0.8-1.2 parts by weight of silicone oil, parts by weight of triethanolamine 0.25-0.5, sodium nitrate 0.95-1.3 by weight, stearic acid 2.3-2.8, antioxidant 0.3-0.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com