Method for separating alcohol-water system by extracting through using hydrophobic Fe-based ionic liquid

A technology of iron-based ionic liquid and water system, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of high energy consumption, inability to meet clean production, large investment, etc., and achieve recycling , low saturated vapor pressure and high extraction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Chlorinated 1-butyl-3-methylimidazole ([bmim]Cl) and ferric chloride hexahydrate (FeCl) in a molar ratio of 1:2 3 ·6H 2 O) as a raw material, placed in an open environment and stirred for 24 hours, and removed the water phase after centrifugation to obtain the hydrophobic ionic liquid [bmim]FeCl 4 ([n-C 4 h 9 -C 3 h 3 N 2 -CH 3 ]FeCl 4 ), and dried in a vacuum oven at 343.2K for 24 hours before use.

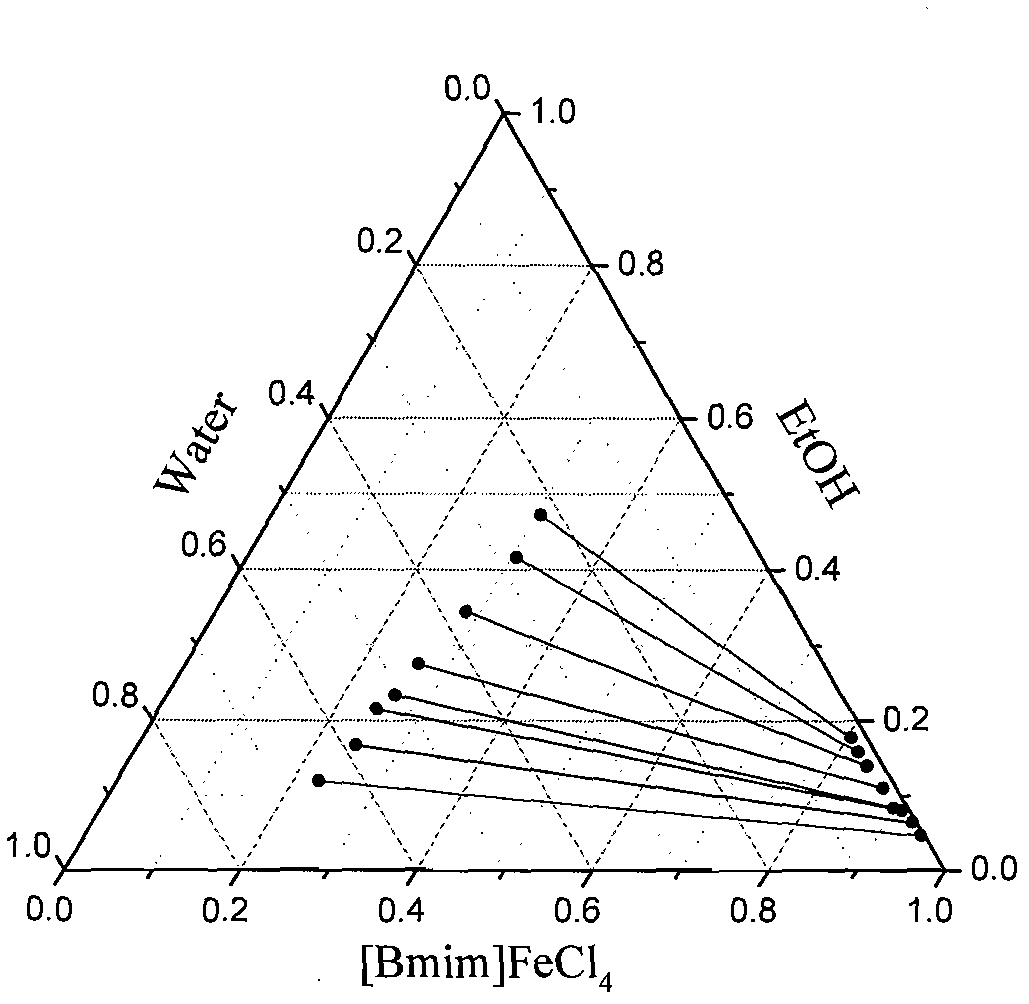

[0046] Add 10 g of ionic liquid [bmim]FeCl to a jacketed mixing kettle 4 , 10g deionized water and 1g ethanol, control the system temperature to 273.2K±0.1K through an ice bath device, place the mixing kettle on a magnetic stirring device, stir magnetically for 2 hours and then let it stand to achieve phase equilibrium.

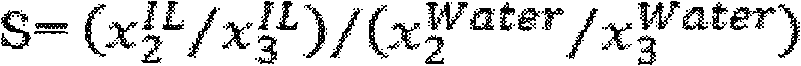

[0047] The system is divided into two layers, and the upper water-rich phase and the lower ionic liquid-rich phase are sampled and analyzed, and the upper and lower phase samples taken out are diluted with deionized water to ionic liquid [bmim]Fe...

Embodiment 2

[0057] Separation was carried out in a method similar to that of Example 1, except that the temperature of the system was controlled at 298.2K.

[0058] As a result, the hydrophobic ionic liquid [bmim]FeCl 4 The selectivity to ethanol is 6.47, and the distribution coefficient of ethanol in the upper and lower phases is 0.1047.

Embodiment 3

[0060] Separation was carried out in a method similar to that of Example 1, except that the temperature of the system was controlled at 313.2K.

[0061] As a result, the hydrophobic ionic liquid [bmim]FeCl 4 The selectivity to ethanol is 19.28, and the distribution coefficient of ethanol in the upper and lower phases is 0.1354.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com