System and method for drying and carbonizing biomass raw material by using boiler flue gas

A technology of biomass raw materials and boiler flue gas, applied in chemical instruments and methods, biofuels, carbon compounds, etc., can solve problems such as difficult large-scale continuous production, high energy consumption, complex system and equipment structure, etc., and achieve easy Continuous production, enhanced heat transfer process, and the effect of avoiding excessive water content in flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

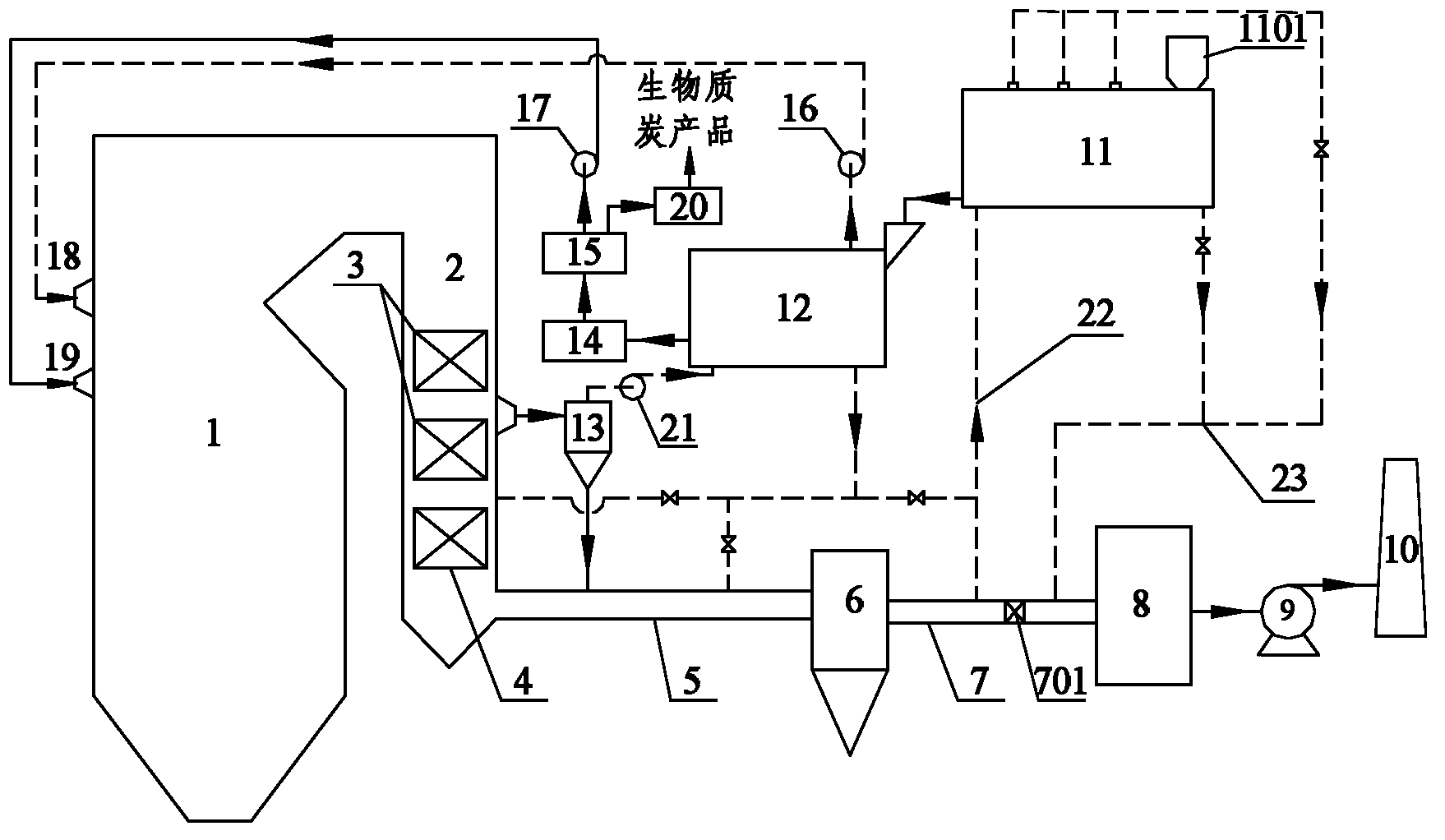

[0022] Such as figure 1 As shown, the system for drying and carbonizing biomass raw materials using boiler flue gas involved in the present invention mainly includes: boiler 1, tail flue 2, economizer 3, air preheater 4, dust removal device 6, desulfurization and dust removal device 8 , induced draft fan 9, biomass drying device 11, biomass carbonization device 12, high temperature pre-dust collector 13, biomass carbon cooling device 14, grinding device 15, pyrolysis gas fan 16, powder discharger 17, pyrolysis gas nozzle 18. Biomass charcoal powder nozzle 19, biochar forming and packaging device 20, etc.

[0023] Coal or biomass fuel is burned in the boiler 1 to generate high-temperature flue gas, and the heat exchange between the high-temperature flue gas and the heating surface (economizer 3, air preheater 4) in the boiler tail flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com