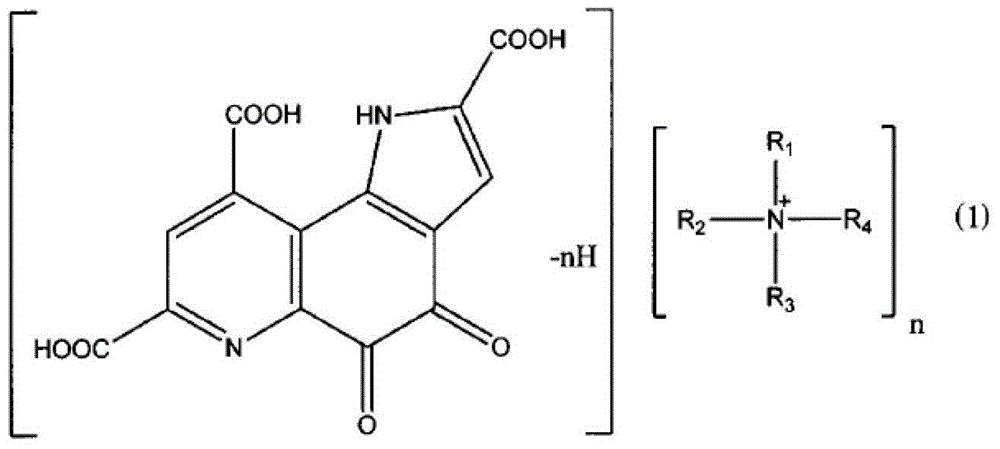

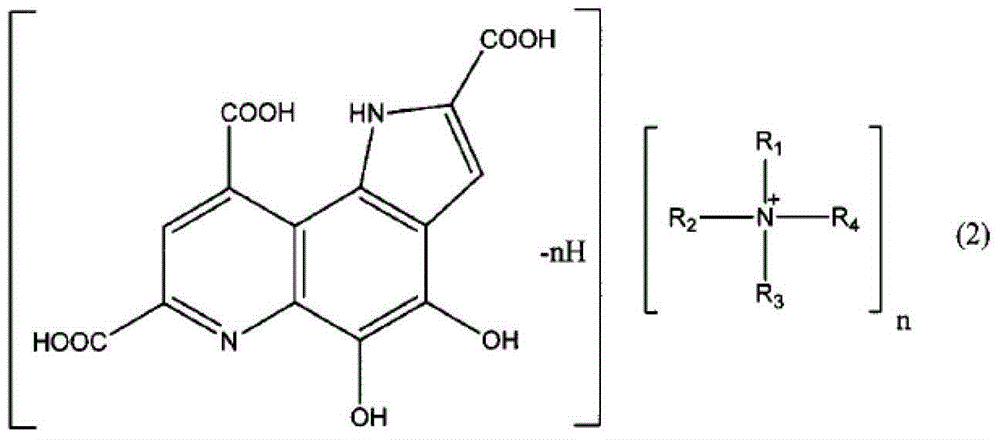

Pyrroloquinoline quinone salt with high solubility and production method thereof

A technology of pyrroloquinoline and its manufacturing method, which can be applied to medical preparations containing active ingredients, pharmaceutical formulas, allergic diseases, etc., and can solve the problems of low solubility and large amount of waste liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

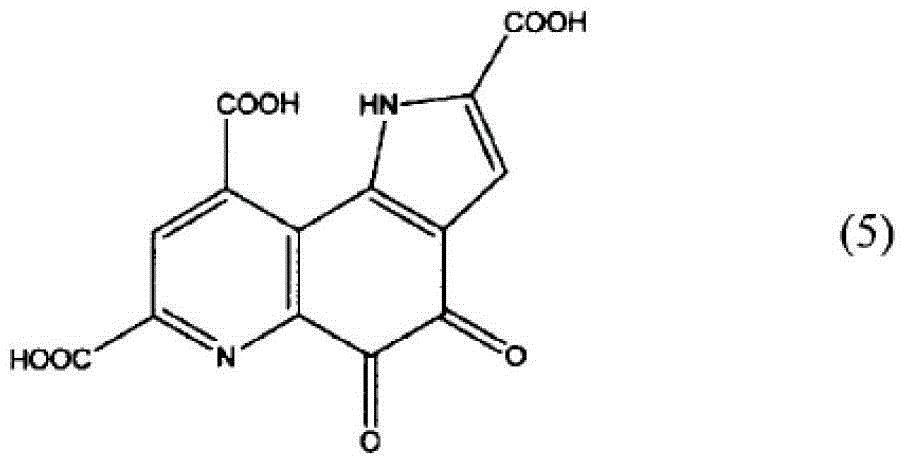

[0079] Embodiment 1: the synthesis of PQQ disodium salt and the modulation of PQQ single choline salt

[0080] Synthesis of PQQ Disodium Salt

[0081] Based on the embodiment 1 of the patent No. 2692167 bulletin, cultivating the denitrification Phycomicrobium ( Hyphomicrobium denitrificans ) DSM1869, the obtained culture solution was centrifuged to remove the bacteria, and the culture supernatant containing PQQ was obtained. This strain can be obtained from DSM (Deutsche Sammlung von Microorganismen (German Collection of Microorganisms and Cell Cultures)).

[0082] The culture supernatant was passed through a Sephadex G-10 (manufactured by Pharmacia) column to adsorb PQQ, and it was eluted with NaCl aqueous solution. NaCl was further added to the obtained PQQ aqueous solution at pH 7.5 so that the concentration was 60 g / L. Cool to give a solid. The obtained solid was dissolved in water, and the purity of PQQ obtained by UV absorption of high-speed liquid chromatography ...

Embodiment 2

[0089] Embodiment 2: the modulation of PQQ1.4 choline salt

[0090] The same free form of PQQ as in Example 1 was used. Suspend 0.47 g of the free substance in 100 ml of isopropanol. To this was added 0.98 g of an aqueous solution of choline hydroxide (48 to 50%) manufactured by Tokyo Chemical Industry. Becomes a solution as the reaction proceeds. This was put into a 300 ml eggplant-shaped flask, and the solvent was removed using an evaporator, washed with hexane, and dried to obtain 0.97 g of a solid. The solid obtained was soluble in ethanol with a ratio of PQQ to choline of about 1.4. That is, the molar ratio of PQQ and choline is about 1:1.4, which is a variable ratio of PQQ choline salt.

Embodiment 3

[0091] Embodiment 3: the modulation of PQQ dicholine salt

[0092] 1.20 g of the free form of PQQ similar to Example 1 was suspended in 100 ml of water. About 1.8 g of an aqueous solution of choline hydroxide (48 to 50%) manufactured by Tokyo Chemical Industry Co., Ltd. was added thereto, and the pH was adjusted to 3.2 after 30 minutes. This was added to a 300 ml eggplant-shaped flask, and the solvent was removed using an evaporator. The obtained solid was dissolved in a mixed solvent of ethanol and isopropanol, and hexane was added to precipitate a solid. The supernatant was removed using decantation to give a solid. The solid was dried under reduced pressure to obtain 2 g of solid. It was diluted to 0.025mM, and the ultraviolet-visible spectrum (220-700nm) was measured, and the result was the same spectrum as the oxidized sodium salt. The structure of the PQQ is maintained. From LC analysis and ion chromatography analysis, it can be known that the molar ratio of PQQ a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com