Purple sweet potato milk pudding and processing method thereof

A milk pudding and processing method technology, applied in application, food preparation, food science and other directions, can solve the problems of rough taste, damage to the pudding structure, single variety of pudding, etc., and achieves fine and smooth taste, simple and smooth procedures, A refreshing and pleasant effect on the entrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The purple potato milk pudding of this embodiment, its raw material components include: 65g of fresh milk, 1g of whole milk powder, 10g of purple sweet potato, 10g of cream, 10g of sucrose, 0.45g of agar, 0.05g of rose essence, 1.5g of modified starch, water 2g.

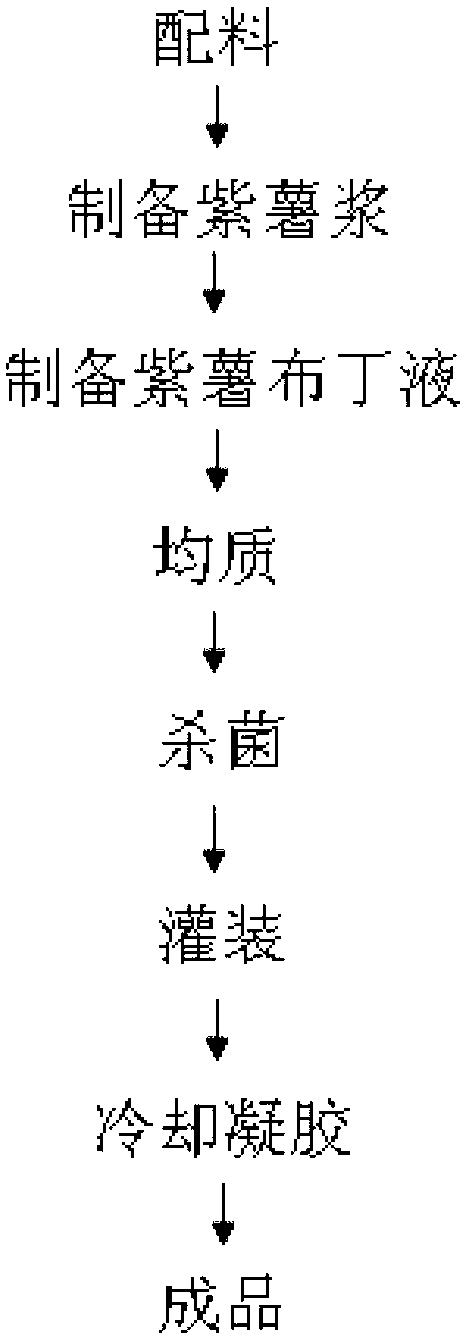

[0068] The preparation method of the purple sweet potato milk pudding of the present embodiment comprises the steps:

[0069] (1) Ingredients: Weigh each ingredient according to the formula and set aside;

[0070] (2) Preparation of purple sweet potato pulp: wash the purple sweet potato with clean water, cook with steam at 100°C for 40 minutes, add fresh milk twice the weight of the purple sweet potato after peeling, and filter the obtained purple sweet potato pulp with a double filter ,spare;

[0071] (3) Preparation of purple potato pudding liquid: heat up the remaining fresh milk to 50°C, slowly add whole milk powder, cream, and modified starch, stir at 1000r / min for 20min, then raise the temperature to 8...

Embodiment 2

[0077] The purple sweet potato milk pudding of this embodiment, its raw material components include: fresh milk 80g, whole milk powder 3g, purple sweet potato 5g, cream 4g, acesulfame potassium 0.2g, agar 0.40g, egg essence 0.125g, modified starch 0.8 g, water 1.65g.

[0078] The preparation method of the purple sweet potato milk pudding of the present embodiment comprises the steps:

[0079] (1) Ingredients: Weigh each ingredient according to the formula and set aside;

[0080] (2) Preparation of purple sweet potato pulp: wash the purple sweet potato with clean water, cook with steam at 121°C for 20 minutes, add fresh milk of 1 times the weight of the purple sweet potato after peeling, and filter the obtained purple sweet potato pulp with a double filter ,spare;

[0081] (3) Preparation of purple potato pudding liquid: heat the remaining fresh milk to 50°C, slowly add whole milk powder, cream, and modified starch, stir at 1000r / min for 15 minutes, then heat the liquid to 75...

Embodiment 3

[0087] The purple sweet potato milk pudding of this embodiment, its raw material components include fresh milk 70g, whole milk powder 2.9g, purple sweet potato 12g, cream 3.5g, maltose 10g, agar 0.50g, vanilla essence 0.1g, modified starch 1.0g.

[0088] The preparation method of the purple sweet potato milk pudding of the present embodiment comprises the steps:

[0089] (1) Ingredients: Weigh each ingredient according to the formula and set aside;

[0090] (2) Preparation of purple sweet potato pulp: wash the purple sweet potato with clean water, cook with steam at 115°C for 30 minutes, add fresh milk 1.5 times the weight of purple sweet potato after peeling, and filter the obtained purple sweet potato pulp with a double filter ,spare;

[0091] (3) Preparation of purple potato pudding liquid: heat the remaining fresh milk to 50°C, slowly add whole milk powder, cream, and modified starch, stir at 1000r / min for 25 minutes, then heat the liquid to 85°C, then add maltose The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com